|

设计描述:

文档包括:

说明书一份,47页,22000字左右.

工艺过程卡片一套

工序卡一套

CAD版本图纸,共9张

………………

摘 要

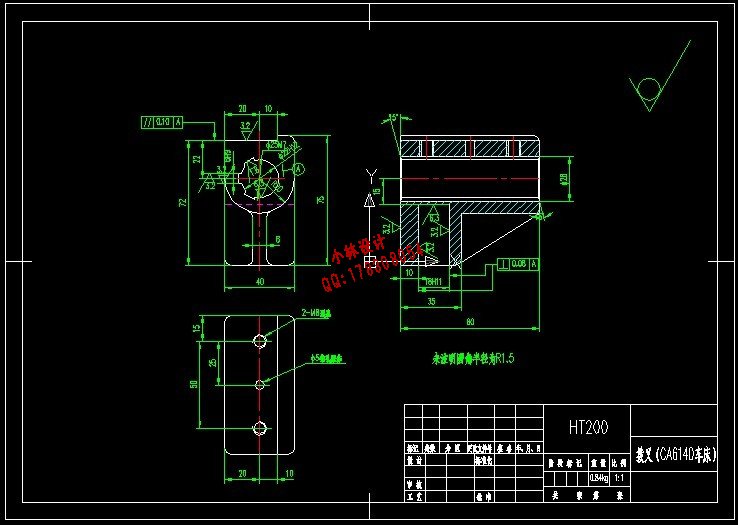

此次设计任务是对拨叉C零件的加工工艺、夹具以及拉刀设计,该工件由于上端面和底槽均与花键孔中心有位置关系,因此在工序安排上,先加工花键孔,再通过花键孔定位加工底槽和上端面,最后攻螺纹孔,其中各种夹具均采用专用夹具,由于该零件的尺寸小,所需的夹紧力不大,因此都采用手动夹紧,它的机构设计简单、方便,且满足夹紧要求。在设计拉刀时,根据零件材料、切削余量等,选择并计算拉刀的各种参数,如拉刀的容屑槽、拉刀齿升量、拉刀齿型及齿数等并根据这些参数画出拉刀工作图。

关键词 拨叉C,加工工艺,定位,夹紧,拉刀

ABSTRACT

This design is to analyze the processing of plectrum C,tongs designs,and pulling knife designs,Because during the machining process,the top end and bottom slot of the workpiece are related to the core position of the key bore.then passes to spend key bore fixed position process the bottom slot with top end,offend the chread bore finally.And every kind of tongs adopt the appropriation tongs.Because such workpiece is small in its size and calls for a little clip tight,therefore all tongs adopt moving to clip tight.Its arganization design is simple,convenience,and satifly to clip tight,when designing the broaching cutting tool,this design choses and computes every kind of parameters,such as,the material of the broaching cutting tool,the rising level of the broaching cutting tool,the type of the pulling knife gear,and the number of the gears and so on,through the material of spare parts and cutting remaining measures,

Key words Plectrum C, the processing craft, position, clip tight, broaching cutting tool.

目 录

摘要…………………………....………………….……………………...Ⅰ

ABSTRACT.....................................................................................................Ⅱ

1 绪论..........................................................................................................3

2 拨叉C的分析.............................................................................................4

2.1拨叉C的作用...........................................................................................4

2.2拨叉C的工艺分析.....................................................................................4

2.3拨叉C的工艺要求.....................................................................................4

2.4毛坯的选择..............................................................................................5

2.5 本章总结................................................................................................5

3 工艺规程设计.............................................................................................6

3.1加工工艺过程...........................................................................................6

3.2确定各表面加工方案..................................................................................6

3.2.1选择加工方法时,需考虑的因素.............................................................6

3.2.2面的加工...........................................................................................6

3.2.3孔的加工...........................................................................................7

3.2.4槽的加工...........................................................................................7

3.3确定定位基准...........................................................................................7

3.3.1粗基准的选择.....................................................................................7

3.3.2精基准选择的原则...............................................................................8

3.4工艺路线的拟订........................................................................................8

3.4.1工序的合理组合..................................................................................8

3.4.2工序的集中与分散...............................................................................9

3.4.3加工阶段的划分................................................................................10

3.4.4加工工艺路线方案的比较....................................................................11

3.5拨叉C的偏差,加工余量,工序尺寸及毛坯尺寸的确定.......................................12

3.5.1毛坯的结构工艺要求..........................................................................12

3.5.2拨叉C的偏差计算.............................................................................13

3.6确定切削用量及基本工时(机动时间)..........................................................14

3.7时间定额计算及生产安排..........................................................................22

3.7.1钻预制孔.........................................................................................22

3.7.2钻预制孔.........................................................................................23

3.7.3拉 25H7内花键................................................................................23

3.7.4粗、精铣18H11底槽........................................................................................23

3.7.5粗、精铣上端面...............................................................................................24

3.7.6钻、攻2-M8螺纹孔.........................................................................................25

3.8 本章总结..............................................................................................................26

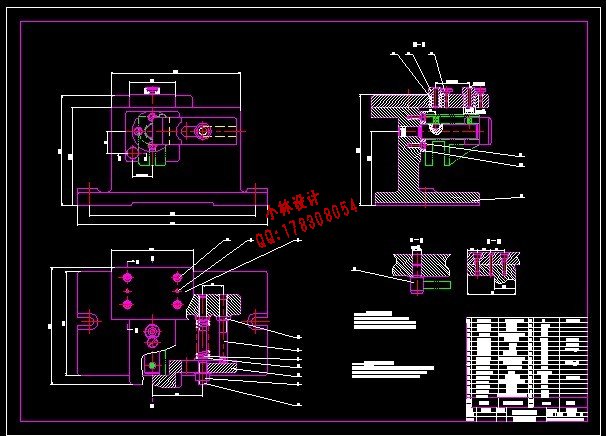

4 专用夹具设计..........................................................................................................27

4.1铣槽夹具设计........................................................................................................27

4.1.1研究原始质料.................................................................................................27

4.1.2定位基准的选择..............................................................................................27

4.1.3夹具方案的设计选择.......................................................................................27

4.1.4切削力及夹紧分析计算...................................................................................27

4.1.5误差分析与计算..............................................................................................29

4.1.6夹具设计及操作的简要说明............................................................................29

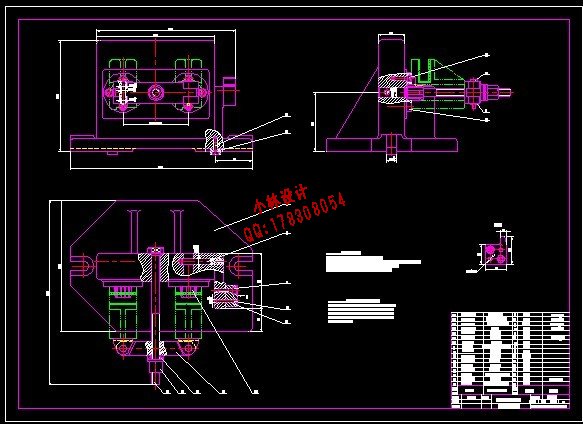

4.2钻、攻2—M8螺纹孔夹具设计..................................................................................30

4.2.1研究原始质料.................................................................................................30

4.2.2定位基准的选择..............................................................................................30

4.2.3夹具方案的设计选择.......................................................................................30

4.2.4切削力及夹紧力的计算...................................................................................30

4.2.5误差分析与计算..............................................................................................31

4.2.6夹具设计及操作的简要说明............................................................................32

4.3 本章总结..............................................................................................................32

5 花键孔 25H7拉刀设计..........................................................................................33

5.1拉刀的结构参数....................................................................................................33

5.1.1拉削特点........................................................................................................33

5.1.2拉刀类型选择.................................................................................................33

5.1.3拉刀材料选择.................................................................................................33

5.1.4拉床类型选择.................................................................................................33

5.2拉刀切削部分的设计.............................................................................................33

5.2.1拉削方式选择.................................................................................................33

5.2.2齿型确定........................................................................................................33

5.2.3拉削余量的确定.............................................................................................34

5.2.4刀齿几何参数选择..........................................................................................34

5.2.5确定齿升量....................................................................................................34

5.2.6确定齿距及同时工作齿数...............................................................................35

5.2.7确定容屑槽形状和尺寸...................................................................................35

5.2.8设计分屑槽.............................................................................../....................36

5.2.9确定拉刀齿数和直径......................................................................................37

5.3拉刀其他部分设计................................................................................................38

5.3.1拉刀柄部设计................................................................................................38

5.3.2颈部与过渡锥部设计......................................................................................38

5.3.3前导部、后导部设计......................................................................................39

5.3.4拉刀总长度....................................................................................................39

5.4拉刀强度及拉床拉力校验......................................................................................40

5.4.1 拉削力..........................................................................................................40

5.4.2 拉刀强度校验................................................................................................41

5.4.3 拉床拉力校验................................................................................................41

5.5 本章总结..............................................................................................................42

6 结论..........................................................................................................................43

参考文献......................................................................................................................44

致 谢............................................................................................................................45

|