|

|

|

|

设计名称 |

铝合金薄壁异型件数控加工及工装设计 |

|

|

设计编号 |

v264 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

13000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

目 录 6.1 数控加工程序……………………………………………… 17

全文总结………………………………………………………… 28

铝合金薄壁异形件主要应用在航空航天等机载设备中,因此要求壁厚薄以达到减轻重量的目的,同时需要保证一定的强度与刚度。通过它将若干只微波器件按一定的相互位置关系装配在一起,按电信设计要求实现微波信号的发射与接收。因此该类零件的加工精度要求更高。铝合金薄壁异形件的种类很多,其尺寸、大小和结构形式随其用途的不同也有很大的差异。一般来说铝合金薄壁异形件的主要结构特点是:有加工精度要求高的安装孔;结构复杂、形状怪异、没有明显基准面;壁厚薄而且不均匀;铝合金材料与一般钢件相比,切削后容易产生切削应力,导致变形等。

关键词:薄壁 异形 机载设备 专用工装 疲劳强度 残余拉应力

The aluminum metal alloy thin wall abnormal shape piece main application at aviation aerospace etc. the machine carries an equipments in, therefore request the wall the purpose that the degree of thickness eases by attaining weight, need to promise certain strength in the meantime with just degree. Pass it press some microwave spare parts certain mutual position to relate to assemble together and press the telecommunication design to request to carry out the blast-off of microwave signal and receives. Therefore that type of spare parts processes accuracy to have higher request. The category of the aluminum metal alloy thin wall abnormal shape piece is a lot of, its size, size and structure form therewith the dissimilarity of use also has very great difference. Generally speaking the main structure characteristics of the aluminum metal alloy thin wall abnormal shape piece Behaves the gearing bore to process accuracy request Goatee structure is complicated, weird shape and have no obvious base level; Wall degree of thickness and asymmetry; The aluminum metal alloy material easily produces to slice to pare in response to the dint after slicing to pare compared with the general steel piece, cause to transform etc.. |

|

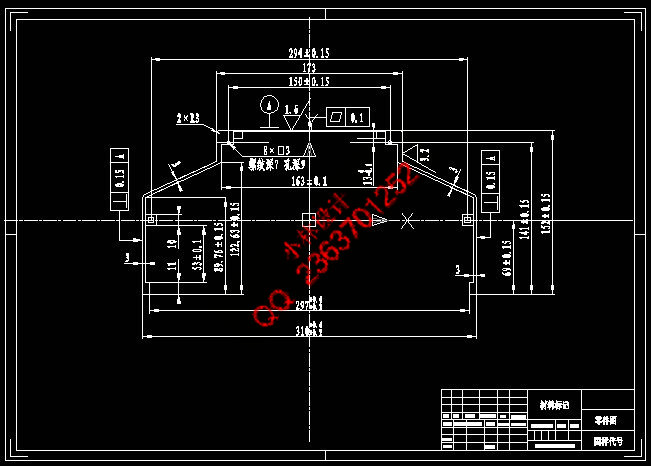

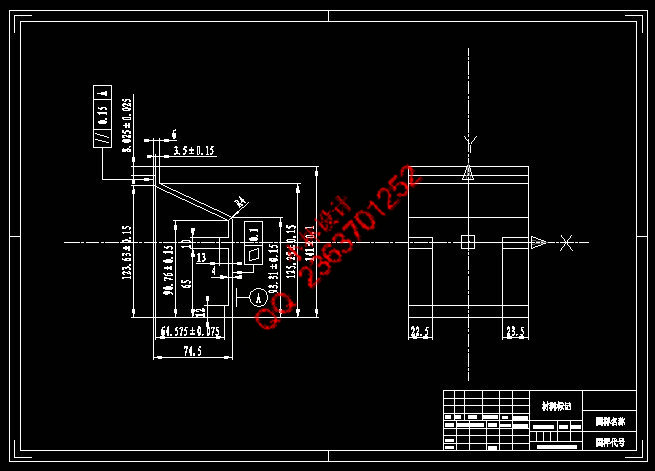

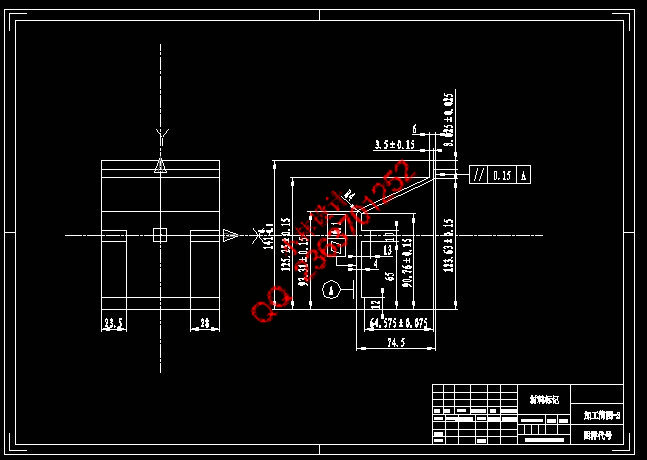

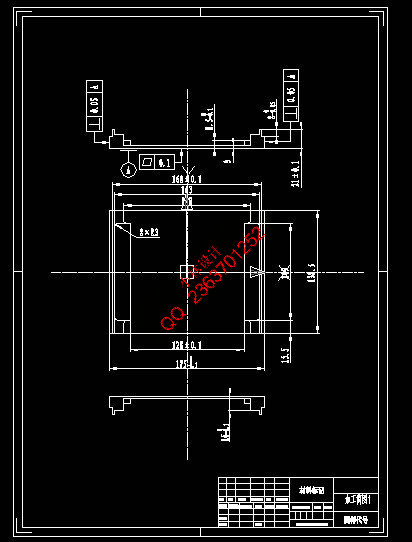

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!