|

设计简介 |

设计描述:

文档包括:

说明书一份,139页,83000字左右.

CAD版本图纸,共5张

………………

毕业设计题目:阳煤新元公司120万吨新井设计

毕业设计专题题目:新元矿巷道贯通时防突措施

毕业设计主要内容和要求:

根据毕业设计大纲的要求,设计的一般部分是阳煤集团新元矿120万吨新井设计,包括五部分。第一部分矿区概述及井田地质特征,第二部分井田开拓,第三部分采煤方法及带区巷道布置,第四部分矿井通风及安全,第五部分矿井安全技术措施。专题部分是对新元矿巷道贯通时防突措施做了介绍。

独立完成上述设计内容、方案论证、计算。分析要正确,主题要有自己的见解。结论要合理,说明书条理要清楚。论述充分,语句通顺。符合专业技术要求,图表完备、正确。

摘 要

本设计包括三个部分,即矿井新井设计部分(一般部分)、专题部分和翻译部分。

一般部分是山西阳煤集团新元矿120万吨井型的新井设计。其内容主要有:

1.井田概况:矿井位于山西省寿阳县境内,地理位置优越,交通便利。井田走向长5.5km,倾斜长3.7km,主要可采煤层有15号煤层,煤层倾角6°左右,属高瓦斯矿井。井田地质条件比较简单。

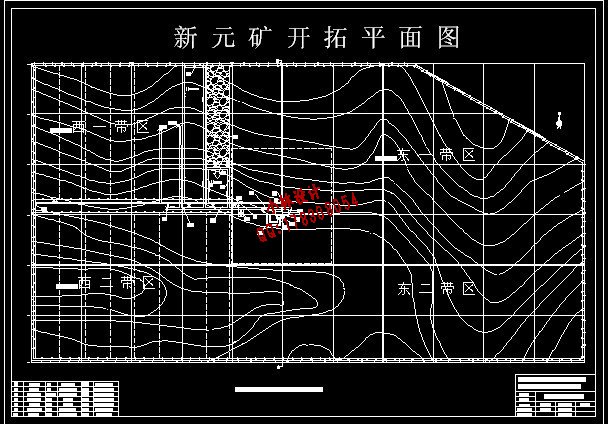

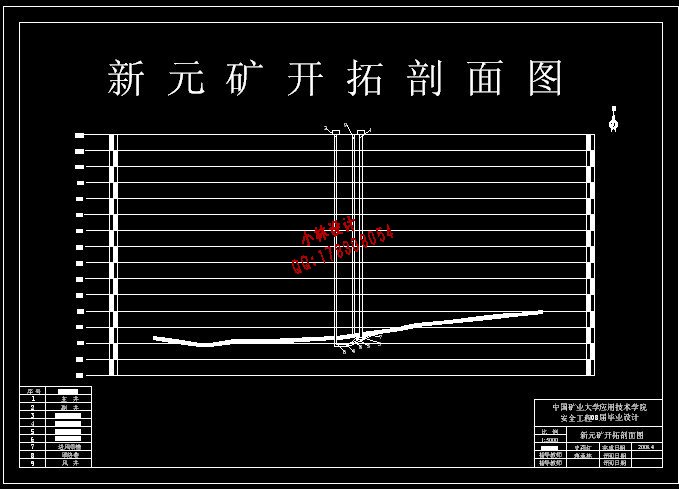

2.开拓开采设计:根据新元矿煤层储存条件及煤炭部设计规范,确定井田采用双立井开拓,水平标高为+670m,矿井服务年限为56年。

3.采煤方法设计:设计工作面采用倾斜长壁采煤法,采用综采采煤工艺,一次采全高,采空区用全部垮落法处理。由一个工作面达到设计产量,工作面生产能力为120.2万t/a。设计工作面采用三八制工作。

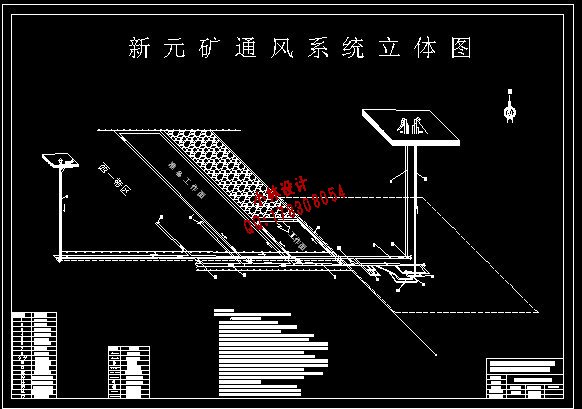

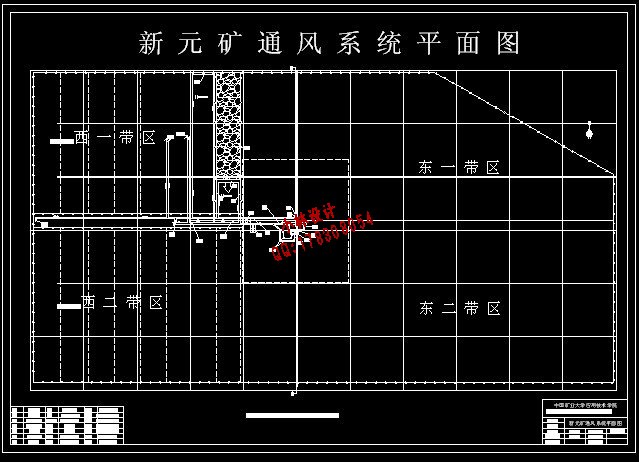

4.矿井通风设计:根据本矿开拓开采条件,采用中央边界式通风,风量分配由内向外计算,工作面采用“U”型通风方式。掘进面用局扇进行压入式通风。根据通风容易、困难时期的通风阻力BDNo24型轴流式风机。矿井通过风机反转反风。

5.井下运输与提升:运煤采用1.2m强力皮带,辅助运输统一采用无轨胶轮车运输方式。主井采用钢丝绳强力皮带提煤,副井采用无轨胶轮车辅助运输。

6.矿井其他安全技术措施的设计:主要包括防水、瓦斯、煤尘等方面的内容。

专题部分针对新元煤矿属高瓦斯矿井,煤层埋藏深,矿井瓦斯涌出量大,严重影响矿井的安全生产。摸清新元矿瓦斯涌出规律,并制定出一套科学、可靠的瓦斯防治技术,提高矿井瓦斯防治技术水平,确保矿井安全生产。

关键词:高瓦斯 ;倾斜长壁采煤法 ;轴流式风机 ;无轨胶轮车

ABSTRACT

The paper consists of three parts, namely the design of a new mine (the general part), the special part and the part of translation.

The general part is about designing a new mine with production capacity of 1800 thousand tons of Xinyuan Coal Mine in YANGQUAN COAL INDUSTRY GROUP in Shanxi Province. The main is as following:

1. The general of the mine. It is located within the boundaries of Shouyang County in Shanxi Province, with ascendant geographic location and convenient transportation. The mine trend covers 5.5 kilometers long and 3.7kilometers wide. No.15 coal seam is the main minable one, and its dip angle is at an angle of 6 or so, belonging to the type of high density of gas. It has comparatively simple geological conditions.

2. The design for opening up and mining. According to the storage conditions of Xinyuan Coal Mine’s coal seam and the specification for design the Ministry of Coal issued, it is decided that it adopts inclined shaft and vertical shaft to open up the mine, with +670m above level, and that the service life of the mine is 56-year.

3. The design for the method of coal mining. The designed coal faces are adopted long wall mining method along dip and totally mechanized coal mining technique, and to deal with the empty it is used the method of the whole caving in. At a coal face it can reach the planned yield and the average production capacity of the coal faces can reach up to 1200 thousand tons per year. It is used four-shift system.

4. The design for ventilation. In accordance with the conditions of opening up and mining, it is appropriate to adopt divisional ventilation, and the distribution of the wind is computed from the inside to the outside. The coal faces are used “W” type to ventilate. Partial blowers are used for ventilation by high pressure on the stub entry. BDNo24master blowers are suitable for the ventilating resistance of both easy and hard ventilating times. Blowers’ reversal can realize reversal ventilation in the mine.

5. Underground haulage and hoisting. It makes use of 1.2-meter-wide high-power rubber belt to transport coal, and uniformly uses trackless conveyors with rubber wheels as aided-transportation. It uses wire ropes and high-power rubber belts to hoist coal in main shaft, while trackless vehicles with rubber wheels as aided-transportation in auxiliary shaft.

6. The design for other safe techniques in mine. It mainly comprises anti-water, anti-gas, anti-coal dust and so on.

The special part refers to that, Xinyuan Coal Mine is a high-gas mine with a mass of gas emission and its coal seam is very deep, which severely affect the safe production of the mine. Because of the great seam gas content and release on the drifting faces, the over limit gas accidents occur easily in the process of breaking through roadways. To analysis the reason why gas accidents occur in

high gas outburst mines during breaking through roadways, is significant for making efficient safety measures and avoiding gas accidents. I suggest some views on the integrative control over the gas in the galleries of high-gas mines theoretically. It need to find out the regularity of gas emission in Xinyuan Coal Mine and formulate a suit of scientific and reliable technology of gas prevention and cure to heighten the technical level of gas prevention and cure in mine and insure its safe production.

Keywords:high gasses ;incline longwall method ;axial flow fan ;railless plastic core-rubber-tires vehicle

目 录

1 矿区概述及井田地质特征 1

1.1 矿区概述 1

1.1.1交通位置 1

1.1.2地形地貌 2

1.1.3 河流及水体 2

1.1.4 气象及地震 2

1.1.5矿区工农业生产概况 2

1.1.6煤田开发情况 3

1.1.7水源及电源 3

1.2 井田地质特征 3

1.2.1 井田地质构造 3

1.2.2 水文地质 6

1.2.3 其它有益矿产 8

1.2.4地质勘探程度 9

1.3 煤层特征 10

1.3.1 煤层 10

1.3.2 煤质 11

1.3.3瓦斯 12

1.3.4煤尘及煤的自燃性 12

1.3.5矿井地温 13

2 井田开拓 14

2.1井田境界及可采储量 14

2.1.1井田范围 14

2.1.2可采储量 14

2.1.3矿井设计生产能力及服务年限 17

2.2井田开拓 18

2.2.1井田开拓的基本问题 18

2.2.2井口及工业场地位置的选择 19

2.2.3井田开拓方案: 27

2.2.4矿井基本巷道 28

2.2.5大巷运输设备选择: 38

2.2.6矿井提升 42

3 采煤方法及带区巷道布置 44

3.1煤层的地质特征 44

3.1.1 煤层 44

3.1.2 煤质 45

3.1.3瓦斯 45

3.1.4煤尘及煤的自燃性 45

3.1.5邻近矿井及本井田瓦斯 45

3.2 带区巷道布置及生产系统 46

3.2.1带区走向长度 46

3.2.2分带斜长及数目 46

3.2.3煤柱尺寸的确定 46

3.2.4确定带区巷道的联络方式 47

3.2.5开采顺序 47

3.2.6带区生产系统 47

3.2.7带区生产能力 48

3.3采煤方法 52

3.3.1采煤工艺方式 52

3.3.2回采工作面主要参数的确定 53

3.3.3 带区巷道布置 54

4 矿井通风 60

4.1矿井通风系统选择 60

4.1.1设计原则及考虑因素 60

4.1.2通风方式确定 60

4.1.3通风方法确定 64

4.2带区通风 65

4.2.1带区通风总体要求 65

4.2.2带区通风的基本要求 65

4.2.3工作面通风方式 66

4.3掘进通风 67

4.3.1掘进通风方法 67

4.3.2掘进面需风量计算 69

4.3.3掘进面的设计 70

4.4矿井需风量 72

4.4.1矿井需风量计算的标准及原则 72

4.4.2矿井需风量的计算 73

4.4.3风量分配 77

4.4.4通风构筑物 78

4.5矿井通风阻力计算 78

4.5.1矿井通风阻力 78

4.5.2矿井总风阻、等积孔计算 83

4.6矿井主要风机选型 84

4.6.1主要风机选型 84

4.6.2电动机选型 89

4.7矿井反风措施及装置 90

4.7.1矿井反风的目的和意义 90

4.7.2反风方法及反风装置 90

4.7.3区域性反风和局部反风 91

4.7.4通风机房布置图 91

4.8概算矿井通风费用 92

4.9阻止特殊灾害事故的安全措施 95

4.9.1防治瓦斯爆炸的措施 95

4.9.2防火措施 95

4.9.3防水制度 95

4.9.4防尘制度 96

4.9.5预防自燃的措施 96

4.9.6 预防井下水灾的措施 96

5粉尘灾害防治 98

5.1粉尘 98

5.2防尘措施 98

5.2.1防尘措施 98

5.2.2采掘工作面防尘、降尘措施 99

5.2.3煤层注水防尘及注水系统 100

5.2.4井下消防、洒水(给水)系统 102

5.3防爆措施 104

5.3.1预防煤尘爆炸的一般性措施 104

5.3.2井下电气设备防爆措施 104

5.4隔爆措施 105

5.4.1隔爆措施 105

5.4.2隔爆水棚 106

5.5矿井地面生产系统防尘 109

5.5.1防尘系统简介 109

5.5.2防尘措施及装备 109

5.6煤尘爆炸 116

5.6.1煤尘爆炸的机理及特征 116

5.6.2煤尘爆炸的条件 117

5.6.3影响煤尘爆炸的因素 118

5.6.4煤尘爆炸性鉴定 119

5.6.5预防煤尘爆炸的措施 119

5.6.6煤尘爆炸区别于瓦斯爆炸的特有标志 119

5.7事故预防及处理计划 118

5.7.1避灾路线 118

5.7.2事故期间通风方法 119

参考文献 131

专题 122

新元矿巷道贯通防突措施 122

1. 问题的提出 122

2. 巷道贯通时瓦斯事故隐患分析 123

2.1 矿井瓦斯概况 123

2.2 巷道贯通时瓦斯事故隐患的形成 123

2.3 原因分析 124

3. 解决的办法和措施 124

3.1选择巷道贯通地点应注意的几个问题 124

3.2 巷道贯通要采取的措施 125

4.工作面与尾巷(回风斜巷)贯通安全技术措施 128

致谢 132

|