|

设计描述:

文档包括:

说明书一份,122页,75000字左右.

CAD版本图纸,共6张

摘 要

本设计包括两部分,即矿井设计部分(一般部分)和专题部分。一般部分是邯郸矿业集团陶二矿180万吨井型的设计,其内容共包括五部分:

1. 矿区概述及井田地质特征:介绍了本设计井田的位置交通,本矿地质构造较为复杂,井田东西走向长为9.3公里,南北倾斜宽约为5.3公里,煤层倾角平均约为170,煤厚平均5.8米,矿井服务年限为58年,井田面积约为23平方公里。

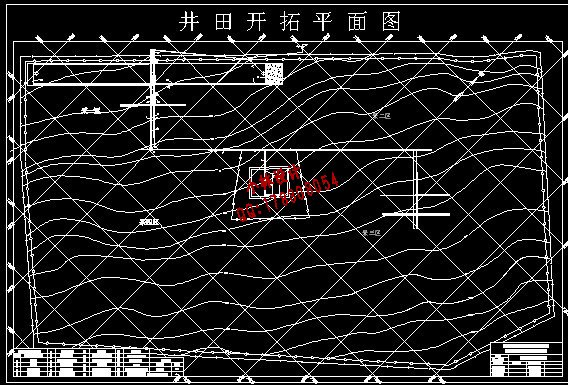

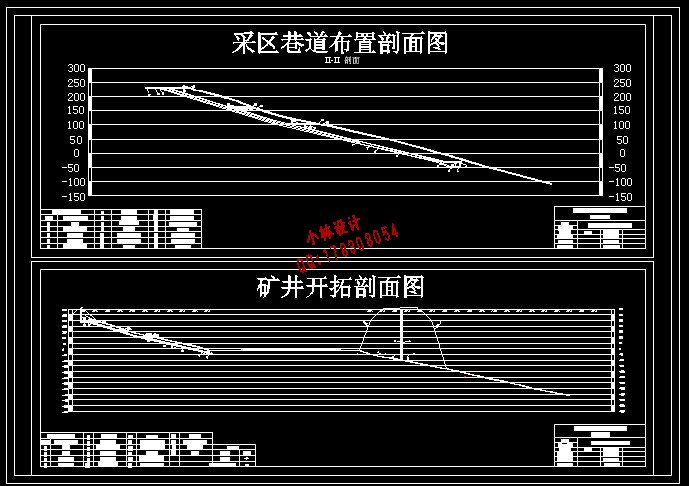

2. 井田开拓:根据陶二矿的煤层赋存条件及矿井设计规范确定本设计矿井采用立井单水平开拓,上、下山开采的开拓开采的方式。

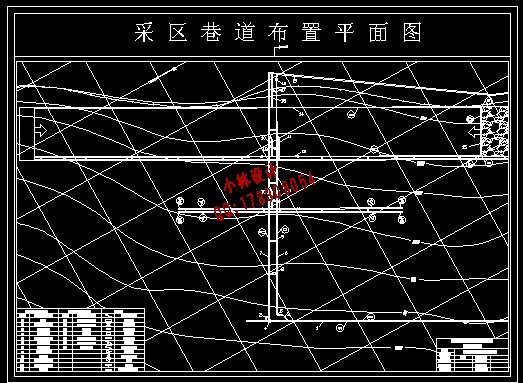

3. 采煤方法设计:由于本设计矿井煤层赋存稳定,倾角较大,平均煤厚5.8米。因此设计采用综采放顶的采煤工艺,采煤工作面长218米,日进6刀,采用走向长壁采煤法的采煤方法。

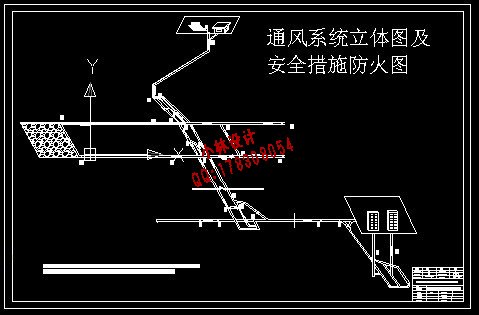

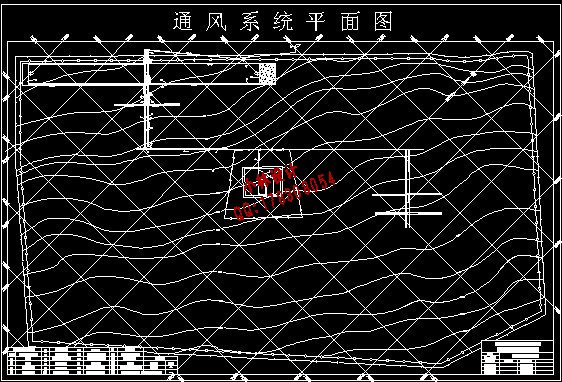

4. 矿井通风设计:根据矿井的开拓开采的条件,设计矿井前期采用中央分列式抽出式通风,后期在保留前期风井的同时采用两翼对角式通风。矿井的风量分配由内向外计算,工作面采用“U型通风”,掘进工作面采用局扇进行抽出式通风,根据矿井通风容易和困难时期的阻力选择主扇,矿井利用反风道反风。

5.矿井抽放设计:陶二矿是低瓦斯矿井,矿井瓦斯相对涌出量为11m3/min ,因此在工作面生产过程中无须进行抽放,才能确保矿井的安全生产。根据工作面生产时的瓦斯涌出量和抽放量确定抽放管材和抽放泵,以及确定矿井的抽放系统。

专题部分是《掘进工作面防突技术现状及问题分析》,并对淮南矿结果同传统的预测方法进行对比分析,从而提出自己的看法。

关键词:瓦斯; 通风; 抽放

ABSTRACT

The design includes two parts, which are mine design part (ordinary part) and special subject part.

The ordinary part is the new mine design of 1800000 tons per year in TAO ER of HANDAN MINING BUREAU, which consists five parts

Part one: Mine fields’ general conditions, which consists locations and transportations of the mine. The geological structure in this mine is much more complicated. Mine field’s strike is about 9.3 kilometers from east to west, and dip direction length is about 5.3 kilometers from north to south. Slope angle is 170 in average .Coal seam thickness is 5.8 meters in average .This mine may be used for 58 years.

Part two: Opening—up and exploiting design. According to the occurrence of coal seam of TAO ER and design norms of the MINISTRY of COAL INDUSTRY, exploiting means of one—level rise and down— dip mining by vertical shaft is used.

Part three: Design of exploiting coal method .The designer uses fully mechanized mining to fit the production capacity. Fully mechanized mining face is 218 meters long; three round ships per day .Long wall caving method along the strike is applied.

Part four: Design of mine ventilation. On the basis of opening—up exploiting conditions of TAO ER, the designer decides to apply the central split exhaust ventilation system at initial mine and diagonal of two wings exhaust ventilation system at last. The method of splitting air flow quantity is based on calculating from interior to exterior. A “U” ventilation system is used in face. Driving faces make use of local fan to precede exhausting method .By biggest resistance of easy or difficult period of ventilation to select the main fan. Revering tunnel is applied to reverse air flow.

Part five: Design about methane exhaust system of coal mine. Because coal seam in TAO ER contains particularly gassy, and they emit relatively about 11m3/t from the coal mines. Hence must be exhaust in coal mine production .Based on the flow of methane to select the system and pump.

Part of the topic is 《Heading Face-process Technology and the Issue of the Status Quo》 and mine in Hainan the forecast results with traditional methods of comparative analysis, which put forward their views.

Key words: gas; ventilation; drainage

目 录

一般设计部分

1矿区概述及井田地质特征............................................1

1.1矿区概述....................................................1

1.2井田地质特征................................................3

1.3煤层特征....................................................6

2井田开拓..........................................................9

2.1井田境界及可采储量..........................................9

2.1.1井田境界..................................................9

2.1.2可采储量..................................................9

2.1.3矿井设计生产能力及服务年限...............................13

2.2 井田开拓..................................................15

2.2.1井田开拓的基本问题.......................................15

2.2.2矿井基本巷道.............................................24

2.2.3矿井提升.................................................34

3采煤方法及采区巷道布置...........................................36

3.1煤层的地质特征.............................................36

3.2采区巷道布置及生产系统.....................................37

3.3采煤方法...................................................41

3.3.1采煤工艺方式.............................................41

3.3.2回采巷道布置.............................................47

4矿井通风.........................................................49

4.1矿井通风系统选择...........................................48

4.2采区通风...................................................53

4.3掘进通风...................................................56

4.4矿井所需风量...............................................60

4.5矿井通风阻力...............................................67

4.6矿井主要通风机选型.........................................72

4.7矿井反风措施及装置.........................................77

4.8概算矿井通风费用...........................................79

4.9防止特殊灾害的安全措施.....................................80

5矿井安全技术措施.................... .............. .............90

5.1矿井安全技术概况...........................................90

5.2矿井火灾...................................................90

5.2.1矿井自然发火概况.........................................90

5.2.2矿井自然发火分析.........................................90

5.3矿井瓦斯...................................................94

5.3.1矿井瓦斯地质条件............... .........................94

5.3.2矿井及采区瓦斯涌出概况...................................94

5.3.3矿井瓦斯防治措施.........................................95

专题设计部分

1.引言............................................................102

2.突出现状分类....................................................102

3.延期性突出的分析................................................103

4.瓦斯抽放技术....................................................111

5.存在的问题及思考................................................115

6.结语............................................................116

参考文献..........................................................118

致 谢............................................................120

|