|

设计描述:

文档包括:

设计说明书1份,共154页,约88000字左右

CAD版本图纸,共5张

毕业设计任务书

毕业论文题目: 国投新集刘庄煤矿1.5Mt/a新井设计

毕业论文专题题目: 低透气性煤层群无煤柱煤与瓦斯共采技术

毕业论文主要内容和要求:

摘 要

本设计包括三个部分:一般部分、专题部分和翻译部分。

一般部分为国投新集刘庄煤矿1.5Mt/a新井设计。刘庄煤矿位于安徽省阜阳市颍上县北部,南距县城约20km,西至阜阳市40km左右。井田走向(东西)长度约6.35km,倾斜(南北)宽度约2.25km,井田总面积约13.3km2。主采煤层为13-1煤和11-2煤,其中13-1煤位于11-2煤上部,两煤层间距平均约70m,煤层倾角为4°~17.5°,平均约12°,属于缓倾斜煤层,煤层平均总厚为13-1煤4.24m、11-2煤3.29m。井田地质条件较为简单。

井田工业储量为140.28Mt,矿井可采储量106.68Mt。矿井服务年限为54.7a,第一水平服务年限54.7a。矿井正常涌水量为550m3/h,最大涌水量为960m3/h。矿井最大相对瓦斯涌出量8.7 m3/t,属于低瓦斯矿井。

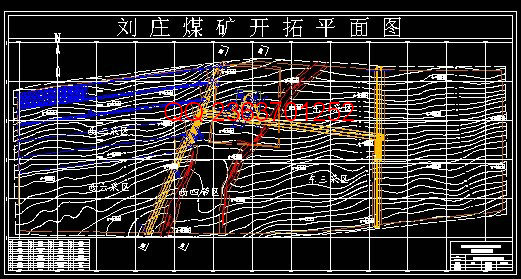

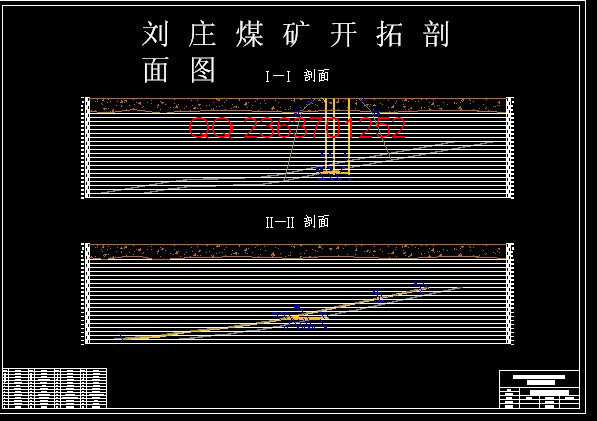

井田开拓方式为立井单水平上下山开拓。大巷采用胶带输送机运煤,辅助运输采用电机车牵引固定矿车运料。矿井通风方式为中央并列式通风。

矿井年工作日为330d,工作制度为“四六”制。

一般部分共包括10章:1、矿区概述及井田地质特征;2、井田境界和储量;3、矿井工作制度及设计生产能力;4、井田开拓;5、准备方式—采区巷道布置;6、采煤方法;7、井下运输;8、矿井提升;9、矿井通风与安全技术;10、矿井基本技术经济指标。

专题部分题目是低透气性煤层群无煤柱煤与瓦斯共采技术。

翻译部分主要内容是一种新型的无支护水力冲洗长壁采煤方法,其英文题目为:Hydraulic Sluiced Longwall Mining Without Supports。

关键词:单水平;井田开拓;中央并列式通风;无支护;水力采煤

ABSTRACT

This design consists of three parts: the general part, special subject part and translated part.

The general part is a new design for LiuZhuang mine. LiuZhuang mine is located in the North of YingShang county in FuYang city of AnHui province. It is about 20 km south to the county and 40 km west to the city. The length of the minefield is about 6.35 km and the width is about 2.25 km with a total area of 13.3 km2. The 13# and 12# is the main coal seam. And the 13# is above the 12# with a vertical distanceof about 70 m. The dip angle of the coal is 4~17.5 degree and the average one is 12 degree. The average thickness of the coal is 4.24 m in 13# and 3.29 m in 12#. The geologic structure of this minefield is simple.

The proved recoverable reserves of the minefield are 140.28 million tons, and the minable reserves are 106.68 million tons. The designed productive capacity is 1.5 million tons per year, and the service life of the mine is 54.7 years. The normal flow of the mine is 550 m3 per hour and the max flow of the mine is 960 m3 per hour. The relative mine gas gush is 8.7 m3/t, It is a low gas mine.

The mine is a single level in three shafts to develop. The central laneway uses Belt Conveyor to transit coal, and trolley wagons are used for accessorial transportation in the roadway.The ventilation mode of this mine is center juxtapose form.

The “four-six” working system is used in the mine. It produces for 330 days a year.

This design includes ten chapters: 1. An outline of the mine field geology; 2. Boundary and the reserves of mine; 3. The service life and working system of mine; 4. Development engineering of coalfield; 5. The layout of panels; 6. The method used in coal mining; 7. Underground transportation of the mine; 8. The lifting of the mine; 9. The ventilation and the safety operation of the mine; 10. The basic economic and technical norms of the designed mine.

The topic of special subject parts is Technique of Integrated Pillarless Coal Production and Methane Extraction in Multiseams of Low Permeability.

Translation part is about a kind of mining method using hydraulic sluicing technique. Its English title is “Hydraulic Sluiced Longwall Mining Without Supports”.

Keywords:Single level; Development engineering of coalfield; Center juxtapose ventilation; Without supports; Hydraulic mining

目 录

一般部分

1 矿区概况及井田地质特征 3

1.1矿区概况 3

1.2井田地质特征 3

1.3煤层特征 3

2 井田境界与储量 3

2.1井田境界 3

2.2矿井储量计算 3

3 矿井工作制度、设计生产能力及服务年限 3

3.1矿井工作制度 3

3.2矿井设计生产能力及服务年限 3

4 井田开拓 3

4.1井田开拓的基本问题 3

4.2矿井基本巷道 3

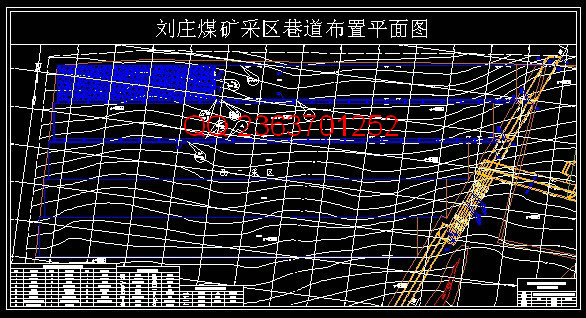

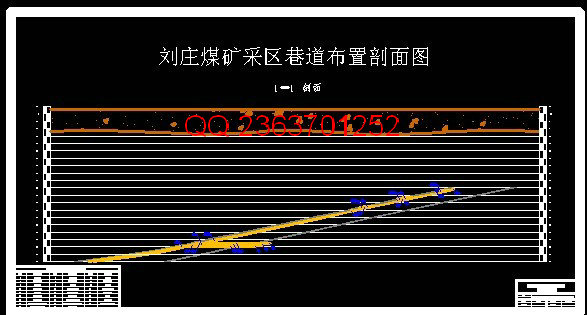

5 准备方式 采区巷道布置 3

5.1煤层的地质特征 3

5.2采区巷道布置及生产系统 3

5.3采区车场选型设计 3

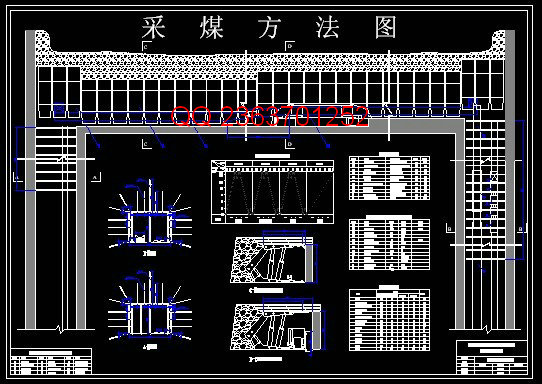

6 采煤方法 3

6.1采煤工艺方式 3

6.2回采巷道布置 3

7 井下运输 3

7.1概述 3

7.2采区运输设备选择 3

7.3大巷运输设备选择 3

8 矿井提升 3

8.1概述 3

8.2主副井提升 3

9 矿井通风及安全技术 3

9.1矿井概况、开拓方式及开拓方法 3

9.2矿井通风系统的确定 3

9.3矿井风量计算 3

9.4矿井阻力计算 3

9.5选择矿井通风设备 3

9.6安全灾害的预防措施 3

10 设计矿井基本技术经济指标 3

参考文献 3

专题部分

低透气性煤层群无煤柱煤与瓦斯共采技术 3

1 引言 3

2 无煤柱煤与瓦斯共采技术思路的提出 3

3 无煤柱留巷钻孔法抽采瓦斯技术 3

3.1留巷钻孔法抽采卸压瓦斯机理 3

3.2抽采首采关键层采空区瓦斯技术 3

3.3抽采远程卸压煤层瓦斯技术 3

4 谢一煤矿望峰岗井煤与瓦斯共采实践 3

4.1试验工作面概况 3

4.2沿空留巷设计 3

4.3立体瓦斯抽采设计 3

4.4工作面设备及参数 3

4.5煤与瓦斯共采效果考察与分析 3

4.6结论及建议 3

5 主要结论 3

参考文献 3

翻译部分

英文原文 3

HYDRAULIC SLUICED LONGWALL MINING WITHOUT SUPPORTS 3

中文译文 3

无支护水力冲洗长壁采煤法 3

致谢 3

|