|

设计描述:

文档包括:

设计说明书1份,共136页,约67000字左右

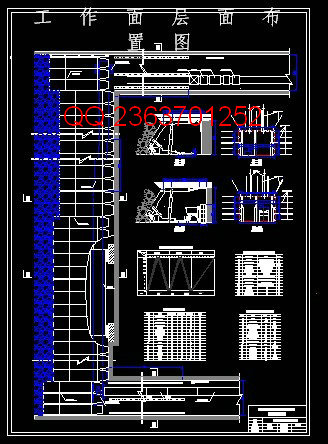

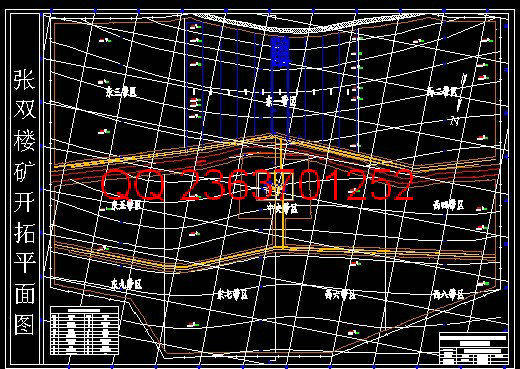

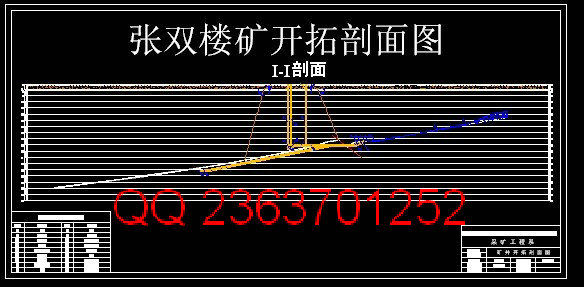

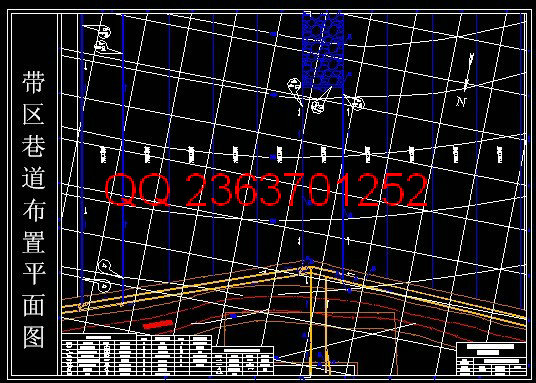

CAD版本图纸,共6张

毕业设计任务书

毕业论文题目: 张双楼煤矿1.2 Mt/a新井设计

毕业论文专题题目: 特殊地段的煤巷支护技术

毕业论文主要内容和要求:

按照采矿工程专业毕业设计大纲要求,完成一般部分张双楼煤矿1.2Mt/a新井设计和专题部分特殊地段的煤巷支护技术,英译汉中文字数3000以上。

摘 要

本设计包括三个部分:一般部分、专题部分和翻译部分。

一般部分为张双楼煤矿1. 2 Mt/a新井设计。一般部分共包括10章:1.矿区概述及井田地质特征;2.井田境界和储量;3.矿井工作制度及设计生产能力、服务年限;4.井田开拓;5.准备方式-带区巷道布置;6.采煤方法;7.井下运输;8.矿井提升;9.矿井通风与安全技术;10.矿井基本技术经济指标。

张双楼煤矿位于徐州市西北,距徐州市约79 km,交通甚为便利。井田走向长约5.2 km,倾向长约2.9 km,面积约20.28 km2。井田内主采煤层为一层,为7#煤。煤层倾角平均为9°,平均厚度5.0 m。井田地质条件较为简单。

矿井工业储量为147.68 Mt,可采储量为108.54万t。矿井设计生产能力为1.2Mt/a。矿井服务年限64.6 a。矿井正常涌水量为320 m3/h,最大涌水量为340 m3/h。矿井相对瓦斯涌出量为0.77 m3/t,属低瓦斯矿井。矿井煤尘有爆炸危险性,煤层无自然发火危险性。

矿井采用立井两水平暗斜井延深开拓。一矿一面,采煤方法为综合机械化一次采全高开采。全矿采用胶带运输机运煤,辅助运输采用矿车。矿井通风方式为中央并列式。

矿井年工作日为330 d,日净提升时间16h,工作制度为“三八制”。

专题部分题目是特殊地段的煤巷支护技术。针对特殊地段的煤巷支护问题,分析特殊地段下围岩变形机理、应力分布规律以及巷道支护原理,确定合理的支护方式,进而保证煤巷围岩的稳定,矿井的生产安全。

翻译部分是一篇关于软岩巷道支护强度与围岩变形关系的论文,英文题目为The optimal support intensity for coal mine roadway tunnels in soft rocks。

关键词:立井两水平;暗斜井延深;带区;一次采全高;中央并列式通风

ABSTRACT

This design includes three parts: the general part, special subject part and translation part.

The general part is a new design of Zhang Shuanglou mine. This design includes ten chapters: 1.An outline of the mine field geology; 2.Boundary and the reserves of mine; 3.The service life and working system of mine; 4.Development of mine; 5.The layout of mining area; 6.The method used in coal mining; 7. Transportation of the underground; 8.The lifting of the mine; 9. The ventilation and the safety operation of the mine; 10.The basic economic and technical norms.

Zhang Shuanglou mine locates at the northwest of XuZhou, 79 km away from the center of the town. And it has convenience transportations. Minefield has a length of 5.2 km in the east and west direction while a width of 2.9 km in the south and north direction on average. The total area is Approximately 20.28 km2. The main coal seam in the mine is only one, which is the 7# coal seam. The average angle is 9 degree, while the thickness is about 5.0 m. The minefield geological condition is simple.

The proved reserves of the minefield are 147.68 million tons. The recoverable reserves are 108.54 million tons. The designed productive capacity is 1.2 million tons per year. The service life is 64.6 years. The normal flow of the mine is 320 m3 per hour and the max flow of the mine is 340 m3 per hour. The Relative gas discharge quantity is 0.77 m3 per ton. Thus it is Low gaseous mine. The coal dust of the mine has explosion hazard. But the coal seam has no spontaneous combustion.

The development of the mine is two level of vertical shaft,deepening with Inclined Shaft. The number of the working faces is only one. Fully mechanized mining overall high extraction is the mining method. Several belt conveyers undertake the job of coal transport in the mine, while the auxiliary transportation system depends on the mine cars. The ventilation type is centralized juxtapose.

The working days in a year are 330. Everyday it takes 16 hours in lifting the coal. The working system in the mine is “three-eight”.The title of the special subject part is “Support technology in special lot of roadway”. In view of roadway special lot’s support issues, analysising mechanism of rock deformation, stress distribution and roadway support principle, determining reasonable support patterns, thus ensuring the stability of surrounding rock, production safety of coal mine.

The translated academic paper is about the relationship between support intensity and rock deformation of roadway tunnels in soft rock. Its title is “The optimal support intensity for coal mine roadway tunnels in soft rocks”.

Keywords: two level of vertical shaft; deepening with Inclined Shaft;strip district; Comprehensive Mechanized mining overall high extraction; centralized juxtapose ventilation

目 录

一般部分

1 矿区概述及井田地质特征 3

1.1矿区概述 3

1.2井田地质特征 3

1.3煤层特征 3

2 井田境界和储量 3

2.1井田范围 3

2.2 矿井工业储量 3

2.3矿井可采储量 3

3 矿井工作制度、设计生产能力及服务年限 3

3.1矿井工作制度 3

3.2矿井设计生产能力及服务年限 3

4 井田开拓 3

4.1井田开拓的基本问题 3

4.2 矿井基本巷道 3

5 准备方式——带区巷道布置 3

5.1煤层地质特征 3

5.2 带区巷道布置及生产系统 3

5.3带区车场选型设计 3

6 采煤方法 3

6.1 采煤工艺方式 3

6.2回采巷道布置 3

7 井下运输 3

7.1概述 3

7.2带区运输设备选择 3

7.3大巷运输设备选型 3

8 矿井提升 3

8.1矿井提升概述 3

8.2主副井提升 3

9 矿井通风及安全 3

9.1矿井地质、开拓、开采概况 3

9.2矿井通风系统的确定 3

9.3带区及矿井所需风量 3

9.4全矿通风阻力计算 3

9.5矿井通风设备选型 3

9.6安全灾害的预防措施 3

10设计矿井基本技术经济指标 3

专题部分

特殊地段的煤巷支护技术 3

0引言 3

1巷道支护体破坏的力学过程 3

2常见巷道支护方法 3

3 特殊地段的煤巷支护 3

4总结 3

参考文献 3

翻译部分

英文原文 3

中文译文 3

致 谢 3

|