|

设计简介 |

设计描述:

文档包括:

PDF版设计说明书1份,共114页

CAD版本图纸,共5张

毕业设计说明书

毕业设计题目: 张双楼煤矿1.8 Mt/a 新井设计

毕业设计专题题目: 煤岩冲击倾向性及物理力学性质测定

毕业设计主要内容和要求:

以实习矿井张双楼煤矿条件为基础,完成张双楼煤矿1.8 Mt/a 新井设计。

主要内容包括:矿井概况、矿井工作制度及设计生产能力、井田开拓、首采

区设计、采煤方法、矿井通风系统、矿井运输提升等。

结合煤矿生产前沿及矿井设计情况,撰写一篇关于煤岩冲击倾向性及物

理力学性质测定的专题论文。

完成冲击矿压电磁辐射监测方面的科技论文翻译一篇,题目为“EME

rock burst monitoring in coal mine huafeng”。

摘 要

本设计包括三个部分:一般部分、专题部分和翻译部分。

一般部分为张双楼矿1.8 Mt/a 的新井设计。井田走向(东西)长平均约10.27 km,倾

向(南北)长平均约3.29 km,井田水平面积为32.04 km2。主采煤层一层,即7#煤层,平

均倾角18°,厚约5.0 m。井田工业储量224.678 Mt,可采储量153.331 Mt,矿井服务年限

为65.53 a。井田地质条件简单;表土层平均厚度约50 m;矿井正常涌水量为200 m3/h,最

大涌水量为280 m3/h;煤层硬度系数2~3,煤质牌号为气煤44;矿井绝对瓦斯涌出量为

3.73 m3/min,属低瓦斯矿井;煤层有自燃发火倾向,发火期3~6 个月,煤尘具有爆炸危险

性。

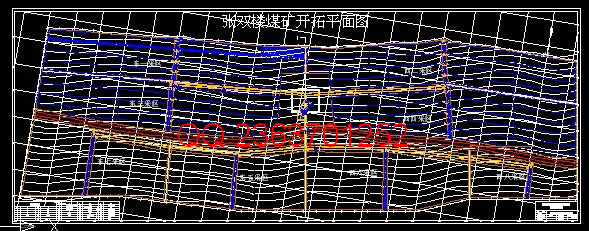

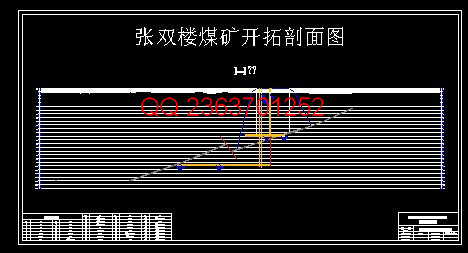

根据井田地质条件,提出四个技术上可行开拓方案。通过技术经济比较,最终确定方

案四为最优方案。将主采煤层划分为两个水平,一水平标高—600 m,二水平标高—1000 m,

因井田走向大断层将井田分为南北两部分,井田南部为一水平服务范围,井田北部为二水

平服务范围。

设计首采区采用采区准备方式,工作面长度170 m,采用一次采全高采煤法,全部跨

落法处理采空区。矿井采用“三八”制作业,两班生产,一班检修。生产班每班3 个循环,

日进6 个循环,循环进尺0.865 m,日产量5632.603 t。

大巷采用带式输送机运煤,辅助运输采用1.5 t 固定箱式矿车。主井装备一套16 t 双箕

斗带平衡锤提煤,副井装备一套带平衡锤的1.5 吨固定车厢式矿车双层四车加宽罐笼。矿

井采用中央并列式通风。通风容易时期矿井总需风量78.78 m3/s,矿井通风总阻力2035.88

Pa,风阻0.328 N·s2/m8,等积孔2.08 m2,矿井通风容易。矿井通风困难时期矿井总风量

78.78 m3/s,矿井通风总阻力2182.84 Pa,风阻0.352 N·s2/m8,等积孔2.01 m2,矿井通风也

较容易。设计矿井的吨煤成本110 元。

专题部分题目是煤岩冲击倾向性及物理力学性质测定。以口孜东煤矿的生产中的煤岩

样测定了口孜东顶板岩层的冲击倾向性和顶板岩层的物理力学性质。

翻译部分是一篇关于电磁辐射在冲击矿压中的应用的论文,英文原文题目为:EME

rock burst monitoring in coal mine huafeng。

关键词:立井;上下山开采;暗立井延伸;双巷掘进;中央并列式

ABSTRACT

This design can be divided into three sections: general design, monographic study and

translation of an academic paper.

The general design is about a 1.8 Mt/a new underground mine design of Zhangshuanglou

coal mine. It’s about 10.27 km on the strike and 3.29 km on the dip,with the 32.04 km2 total

horizontal area. The minable coal seam of this mine is only 7# with an average thickness of 5.0

m and an average dip of 18°. The proved reserves of this coal mine are 224.678 Mt and the

minable reserves are 153.331 Mt, with a mine life of 65.53 a.The geological condition of the

mine is relatively simple. The normal mine inflow is 200 m3/h and the maximum mine inflow is

280 m3/h. It is bituminous coal 44 with low mine gas emission rate and coal spontaneous

combustion tendency, and it’s a coal seam liable to explosion.

Based on the geological condition of the mine, I bring forward four available project in

technology. The fourth project is the best comparing with other three project in technology and

economy. The first level is at -600 m, The second level is at -1000 m, Because a major fault lies

in the center of mine field, the mine field is divided into the north section and the south section,

the south section is one level service scope, and the north section is two level service scope.

Designed first mining district makes use of the method of preparation in mining area, the

length of working face is 170 m, which uses fully-mechanized coal mining technology, and fully

caving method to deal with goaf. The working system is “three-eight”,with two teams mining,

and the other overhauling. Every mining team makes three working cycle, with six working

cycle everyday. Advance of working cycle is 0.865 m, and quantity of 5632.603 ton coal is

makedeveryday.

Main roadway makes use of belt conveyor to transport coal resource, and mine car to be

assistant transport. Main shaft makes use of skip to transport coal resource, when subsidiary

shaft makes use of cage to be assistant transport. In the prophase of mining the mine makes use

of centralized ventilation method,when in the evening of mining the mine makes use of areas

ventilation method. At the easy time of mine ventilation, the total air quantity is 78.78 m3 per

second, the total mine ventilation resistance is 2035.88 Pa, the coefficient of resistance is 0.328

N·s2/m8, equivalent orifice is 2.08 m2. At the difficult time of mine ventilation, the total air

quantity is about 78.78 m3 per second, the total mine ventilation resistance is 2182.84 Pa, the

coefficient of resistance is 0.352 N·s2/m8, equivalent orifice is 2.01 m2. The cost of the designed

mine is 110 yuan per ton.

The translated academic paper is about EME in the rock burst .

Keywords:shaft; up-dip and down-dip minging; double thunnel drivage; centralized

juxtapose ventilation

目 录

一般部分

1 矿区概述及井田地质特征 ············································································· 1

1.1 矿区概述 ····························································································· 1

1.1.1 矿井地理位置、交通条件 ··································································· 1

1.1.2 矿区经济状况 ·················································································· 1

1.1.3 矿区气候条件 ·················································································· 2

1.1.4 矿区水文情况 ·················································································· 2

1.2 井田地质特征 ······················································································· 3

1.2.1 井田地形与勘探程度 ········································································· 3

1.2.2 井田煤系地层概述 ············································································ 3

1.2.3 井田地质构造、最主要地质变动··························································· 4

1.2.4 井田水文地质特征 ············································································ 6

1.3 煤层特征 ····························································································· 6

1.3.1 煤层 ······························································································ 6

1.3.2 煤层的围岩性质 ··············································································· 7

1.3.3 煤的特征 ························································································ 7

2 井田境界和储量 ························································································· 9

2.1 井田境界 ····························································································· 9

2.1.1 井田范围 ························································································ 9

2.1.2 开采界限 ························································································ 9

2.1.3 井田尺寸 ························································································ 9

2.2 矿井工业储量 ······················································································· 9

2.2.1 井田地质勘探 ················································································ 10

2.2.2 煤层可采厚度 ················································································ 10

2.2.3 矿井工业储量的计算 ······································································· 10

2.3 矿井可采储量 ······················································································ 10

2.3.1 井田边界保护煤柱 ·········································································· 10

2.3.2 工业广场保护煤柱 ··········································································· 11

2.3.3 断层和井筒保护煤柱 ········································································ 11

2.3.4 矿井可采储量 ················································································ 12

3 矿井工作制度、设计生产能力及服务年限 ······················································· 14

3.1 矿井工作制度 ······················································································ 14

3.2 矿井设计生产能力及服务年限 ·································································· 14

3.2.1 确定依据 ······················································································ 14

3.2.2 矿井设计生产能力 ·········································································· 14

3.2.3 矿井服务年限 ················································································ 14

4 井田开拓 ································································································ 164.1 井田开拓的基本问题 ············································································· 16

4.1.1 确定井筒形式、数目、位置及坐标 ······················································ 16

4.1.2 确定工业场地位置、形状和面积························································· 17

4.1.3 开采水平的确定及采区的划分 ··························································· 18

4.1.4 主要开拓巷道 ················································································ 18

4.1.5 开拓方案比较 ················································································ 18

4.2 矿井基本巷道 ······················································································ 23

4.2.1 井筒 ···························································································· 23

4.2.2 井底车场 ······················································································ 25

4.2.3 主要开拓巷道 ················································································ 27

4.2.4 巷道支护 ······················································································ 30

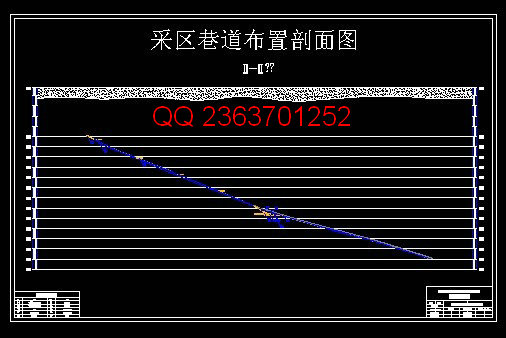

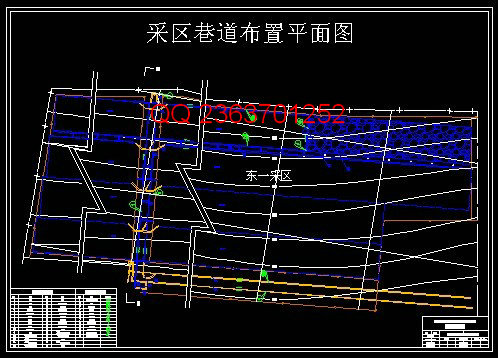

5 准备方式——采区巷道布置 ········································································· 31

5.1 煤层的地质特征 ··················································································· 31

5.1.1 采区位置 ······················································································ 31

5.1.2 采区煤层特征 ················································································ 31

5.1.3 煤层顶底板岩层性质 ······································································· 31

5.1.4 煤层瓦斯与涌水情况 ······································································· 31

5.1.5 地质构造 ······················································································ 31

5.1.6 临近矿井与地表情况 ······································································· 32

5.2 采区巷道布置及生产系统 ······································································· 32

5.2.1 确定采区巷道布置及生产系统的原则 ··················································· 32

5.2.2 采区位置及范围 ············································································· 32

5.2.3 采煤方法及工作面长度的确定 ··························································· 32

5.2.4 确定采区各种巷道的尺寸、支护方式及通风方式 ···································· 32

5.2.5 煤柱尺寸的确定 ············································································· 33

5.2.6 采区巷道的联络方式 ······································································· 33

5.2.7 采区内工作面接替顺序 ···································································· 33

5.2.8 采区生产系统 ················································································ 33

5.2.9 采区内巷道掘进方法 ······································································· 34

5.2.10 采区生产能力及采出率 ··································································· 34

5.3 采区车场选型设计 ················································································ 35

5.3.1 确定采区车场形式 ·········································································· 35

5.3.2 采区主要硐室布置 ·········································································· 37

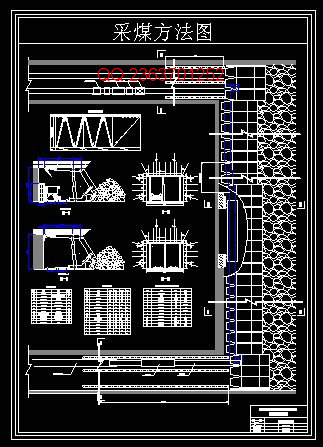

6 采煤方法 ································································································ 38

6.1 采煤工艺方式 ······················································································ 38

6.1.1 采区煤层特征及地质条件 ································································· 38

6.1.2 确定采煤工艺方式 ·········································································· 38

6.1.3 回采工作面参数 ············································································· 39

6.1.4 回采工作面破煤与装煤方式 ······························································ 39

6.1.5 回采工作面支护方式 ······································································· 42

6.1.6 端头支护及超前支护方式 ································································· 43

6.1.7 各工艺过程注意事项 ······································································· 44

6.1.8 回采工作面正规循环作业 ································································· 45

6.2 回采巷道布置 ······················································································ 48

6.2.1 回采巷道布置方式 ·········································································· 48

6.2.2 回采巷道参数 ················································································ 48

7 井下运输 ································································································ 51

7.1 概述 ·································································································· 51

7.1.1 井下运输设计的原始条件和数据························································· 51

7.1.2 运输距离和货载量 ·········································································· 51

7.1.3 矿井运输系统 ················································································ 51

7.2 采区运输设备选择 ················································································ 52

7.2.1 设备选型原则 ················································································ 52

7.2.2 采区设备的选型 ············································································· 52

7.3 大巷运输设备选择 ················································································ 53

7.3.1 运输大巷设备选择 ·········································································· 53

7.3.2 辅助运输大巷设备选择 ···································································· 54

8 矿井提升 ································································································ 56

8.1 概述 ·································································································· 56

8.1.1 矿井提升设计的原始条件和数据························································· 56

8.1.2 主、副井提升方式 ·········································································· 56

8.2 主副井提升 ························································································· 56

8.2.1 主井提升容器选择 ·········································································· 56

8.2.2 副井提升容器选择 ·········································································· 56

9 矿井通风与安全 ························································································ 58

9.1 矿井通风系统选择 ················································································ 58

9.1.1 矿6.1.7 各工艺过程注意事项 ······································································· 44

6.1.8 回采工作面正规循环作业 ································································· 45

6.2 回采巷道布置 ······················································································ 48

6.2.1 回采巷道布置方式 ·········································································· 48

6.2.2 回采巷道参数 ················································································ 48

7 井下运输 ································································································ 51

7.1 概述 ·································································································· 51

7.1.1 井下运输设计的原始条件和数据························································· 51

7.1.2 运输距离和货载量 ·········································································· 51

7.1.3 矿井运输系统 ················································································ 51

7.2 采区运输设备选择 ················································································ 52

7.2.1 设备选型原则 ················································································ 52

7.2.2 采区设备的选型 ············································································· 52

7.3 大巷运输设备选择 ················································································ 53

7.3.1 运输大巷设备选择 ·········································································· 53

7.3.2 辅助运输大巷设备选择 ···································································· 54

8 矿井提升 ································································································ 56

8.1 概述 ·································································································· 56

8.1.1 矿井提升设计的原始条件和数据························································· 56

8.1.2 主、副井提升方式 ·········································································· 56

8.2 主副井提升 ························································································· 56

8.2.1 主井提升容器选择 ·········································································· 56

8.2.2 副井提升容器选择 ·········································································· 56

9 矿井通风与安全 ························································································ 58

9.1 矿井通风系统选择 ················································································ 58

9.1.1 矿井通风系统的基本要求 ································································· 58

9.1.2 矿井通风方式的确定 ······································································· 58

9.1.3 矿井主要通风机工作方式的选择························································· 59

9.1.4 采区通风系统的要求 ······································································· 60

9.1.5 工作面通风方式的选择 ···································································· 60

9.2 采区及全矿所需风量 ············································································· 61

9.2.1 采煤工作面需风量 ·········································································· 61

9.2.2 备用工作面需风量 ·········································································· 62

9.2.3 掘进工作面需风量 ·········································································· 62

9.2.4 硐室需风量 ··················································································· 63

9.2.5 其它巷道所需风量 ·········································································· 63

9.2.6 矿井总风量计算 ············································································· 63

9.2.7 风量分配 ······················································································ 64

9.3 全矿通风阻力的计算 ············································································· 65

9.3.1 矿井通风总阻力计算原则 ································································· 65

9.3.2 容易和困难时期矿井阻力路线的确定 ··················································· 659.3.3 矿井通风阻力计算 ·········································································· 65

9.3.4 矿井通风总阻力计算 ······································································· 66

9.3.5 矿井总风阻和等积孔计算 ································································· 67

9.4 通风机选型 ························································································· 68

9.4.1 选择主要通风机 ············································································· 68

9.4.2 电动机选型 ··················································································· 70

9.5 防止特殊灾害的安全措施 ······································································· 71

9.5.1 预防瓦斯和煤尘爆炸的措施 ······························································ 71

9.5.2 预防井下火灾的措施 ······································································· 72

9.5.3 防水措施 ······················································································ 72

10 设计矿井基本技术经济指标 ······································································· 73

一般部分参考文献 ························································································ 74

专题部分

煤岩冲击倾向性及物理力学性质测定 ································································ 76

1 顶板岩层冲击倾向性测定 ············································································ 76

1.1 概述 ·································································································· 76

1.1.1 顶板岩层冲击倾向性分类及指标························································· 76

1.1.2 顶板岩层冲击倾向性测定方法 ··························································· 76

1.2 采样 ·································································································· 78

1.3 试样加工与试验 ··················································································· 78

1.3.1 试样加工 ······················································································ 78

1.3.2 实验系统 ······················································································ 80

1.4 试验处理结果及分析 ············································································· 80

1.4.1 抗拉强度(tensile strength) ······························································ 80

1.4.2 岩石块体密度(block density of rock) ················································· 81

1.4.3 弹性模量(modulus of elasticity) ························································· 81

1.4.4 弯曲能量指数(bending energy index) ·················································· 81

1.5 主要结论 ···························································································· 81

1.6 主要附图 ···························································································· 82

2 底板岩层物理力学性质 ··············································································· 86

2.1 底板岩样抗压强度的测定 ······································································· 86

2.2 底板岩样弹性模量的测定 ······································································· 86

2.3 底板岩样抗拉强度的测定 ······································································· 87

2.4 底板岩样内聚力、内摩擦角的测定 ···························································· 88

2.5 主要结论 ···························································································· 89

2.6 主要附图 ···························································································· 89

专题部分参考文献 ························································································ 95

翻译英文原文 ··································································································· 97

EME rock burst monitoring in coal mine huafeng ····················································· 97

1 EME mechanism of rock burst failure······························································ 97

1.1 EME Mechanism of Rock Burst Failure ····················································· 97

1.2 EME Phenomena and Experiment Result of Rock Burst ·································· 97

2 forecastinf of rock burst ·············································································· 99

2.1 The principle of EME’s forecasting Rock Burst ··········································· 99

2.2 Methods of the Forecasting Rock Burst ······················································ 99

3 Application of the eme technique ································································· 100

3.1 The Condition of the Tested Working Face ················································· 100

3.2 The KBD5 apparatus ·········································································· 100

3.3 Application of the EME Technique ·························································· 100

3.4 The EME Forecasting Guideline of Rock Burst on the Working Face ·················· 101

3.5 EME Forecasting Accuracy ·································································· 101

4 conclusions ·························································································· 101

中文译文 ································································································· 103

华丰煤矿冲击矿压电磁辐射监测 ···································································· 103

1 冲击矿压的电磁辐射机理 ········································································ 103

1.1 冲击矿压的电磁辐射机理··································································· 103

1.2 冲击矿压的电磁辐射现象和实验结果 ···················································· 103

2 冲击矿压的预报 ··················································································· 104

2.1 电磁辐射预报冲击矿压的原则 ····························································· 104

2.2 冲击矿压预报方法 ··········································································· 105

3 电磁辐射技术的应用 ·············································································· 105

3.1 被测工作面的地质条件 ····································································· 105

3.2KBD5 装置 ····················································································· 105

3.3 电磁辐射技术的应用 ········································································ 106

3.4 电磁辐射预报工作面冲击矿压指标 ······················································· 106

3.5 电磁辐射预报的精确性 ····································································· 107

4 结论 ·································································································· 107

致 谢 ···································································································· 108

|