|

设计描述:

文档包括:

WORD版本设计说明书一份,共103页,约35000字

CAD版本图纸,共4张

赵桥井田通风初步设计

摘要:本设计是根据永城煤电集团赵桥矿的资料对赵桥井田作的初步设计,充分考虑实际情况,综合考虑整个矿井的各个生产系统完成井田的开发。本井田范围内,地质条件简单,瓦斯涌出量很小,涌水量较大,煤层无自燃倾向性。井田面积约为36.47km2,设计可采储量为93.91Mt,年产量1.5Mt/a,服务年限52.06a。采用单水平上下山开拓方式,分为4个带区,7个采区,采用倾斜长壁后退式采煤方法。矿井通风方式为中央并列式,采区和工作面均采用下行通风方式,采用风机反转反风方式反风。采用单环卧式井底车场,轨道大巷运料运人,皮带大巷运煤,副井下料下人,主井提煤。矿井采用集中排水方式。

关键词:赵桥井田 矿井通风 初步设

The Preliminary Design of Zhaoqiao Mine Ventilation

Abstract:This preliminary design is based on the data of YongCheng Coal and Electricity,fully considering practical situation.Comprehensive consider each production system of the wholly shaft to complete the exlloitation of the shaft.In this allotment the geologic condition is simple,the flowing quantity of gases is little,flowing of water is more,,the coal dust without spontaneous combustion.The allotment area is about 36.47km2,the desiged exploitable reserve is93.915Mt,the yearly output is 15Mt/a,the service life is 52.06a.The method of single level UP-AND-DOWN mountain exploiting was adopted.It was divided into eleven mining district.The first division adopt inline length wall backhand welding coalmining method.The other division adopt cross pitch length wall backhand welding coalmining method.The manner of mine ventilation adopt middle side by side type.The division and working face adopt down ventilation system.Adopt the fan reversaling the ventilation manner to resver the ventilation.Adopt single ring horizontai shaft station.The orbit main entry is used to transport people and material.The strap main entry is used to transport coal.Main shaft is used to lift coal and auxiliary shaft understrapper people and material.The shaft adopt concentrated drainage manner.

Keywords: Zhaoqiao mine mine ventilation the preliminary design

目录

1 引 言 1

2 井田概况及井田地质特征 3

2.1 井田概况 3

2.2 井田地质特征 5

3 井田储量、年产量及服务年限 12

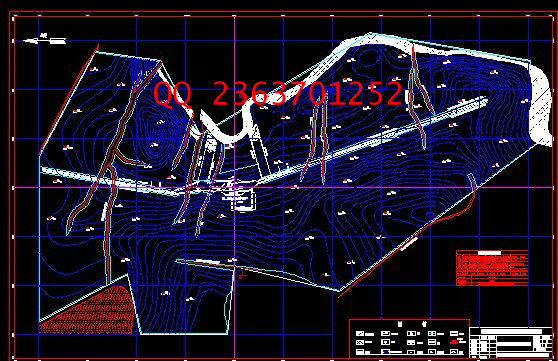

3.1 井田境界 12

3.2 井田储量 13

4 井田开拓 20

4.1 概述 20

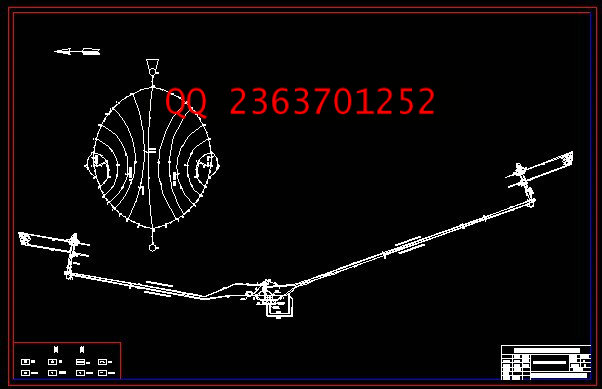

4.2 井田开拓 20

4.3 井筒特征 25

4.4 井底车场及硐室 28

4.5 开采顺序及采区、采煤工作面的配置 31

5 采煤方法 35

5.1 采煤方法选择 35

5.2 采区巷道布置及生产系统? 35

5.3 回采工艺 38

6 矿井运输、提升及排水 41

6.1 井下运输 41

6.2 矿井提升 43

6.3 矿井排水 53

7 矿井通风设计 62

7.1 矿井通风系统的选择 62

7.2 风量计算及风量分配 64

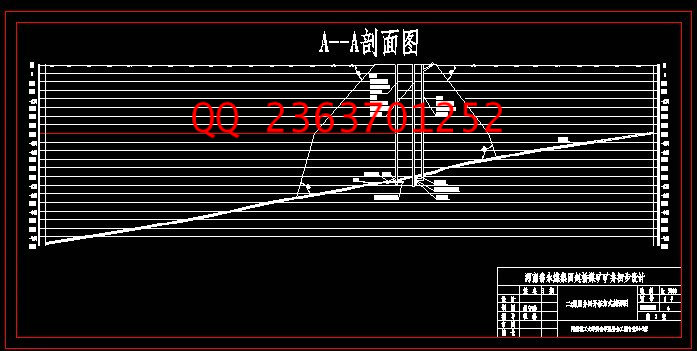

7.3 采区通风设计 68

7.4 掘进工作面通风设计 72

7.6 主要通风机选型 78

7.7 矿井反风措施 82

7.8 矿井通风评价 84

8 矿井安全技术措施 87

8.1 防治水患 87

8.2 防灭火 87

8.3 防止瓦斯爆炸 87

8.4 防尘 88

8.5 顶板 88

8.6 安全监测系统 89

9 矿山环保 90

9.1 污水处理 90

9.2 消烟除尘及粉尘控制 91

9.3 绿化、噪声控制及文物保护 92

9.4 固体废渣处理 92

9.5 地面塌陷与处理 93

9.6 环境保护设施及投资 96

结束语 97

致谢 98

参 考 文 献 99

|