|

文档包括:

word说明书一份,共136页,约59000字

CAD版本图纸,共4张

摘 要

本设计包括三个部分:一般部分,专题部分和翻译部分。

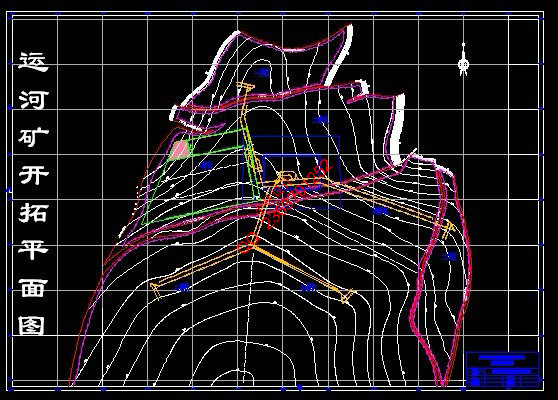

一般部分:运河煤矿的新井设计,共分十个章,矿区概况和井田地质特征,井田境界及储量,矿井工作制度和设计生产能力,井田开拓,准备方式—带区道布置,采煤方法,矿井提升,井下运输,矿井通风,矿井基本技术经济指标。

本井田总面积14km2,南北宽3.5km,东西平均4km,井田内可采煤层为3#煤层,平均厚度为8.64m。煤层赋存稳定,为缓倾斜煤层。属于低瓦斯矿井,煤尘有爆炸危险,有自然发火倾向。

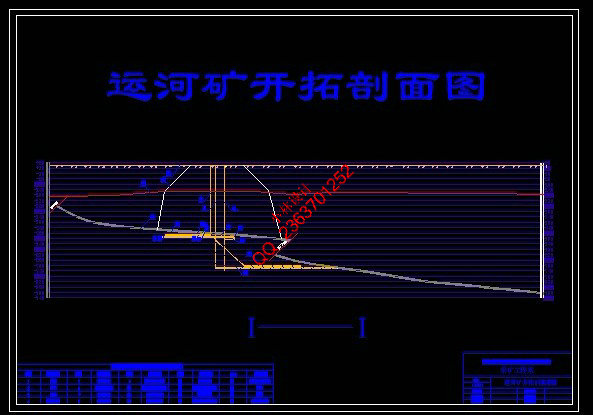

设计生产能力为180万t/a,服务年限为76.1a。工作制度为“四六制”。矿井为两水平直接延伸开拓,第一水平布置在-490m。

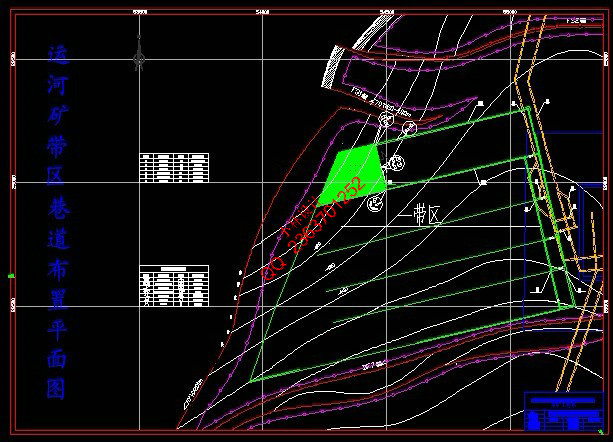

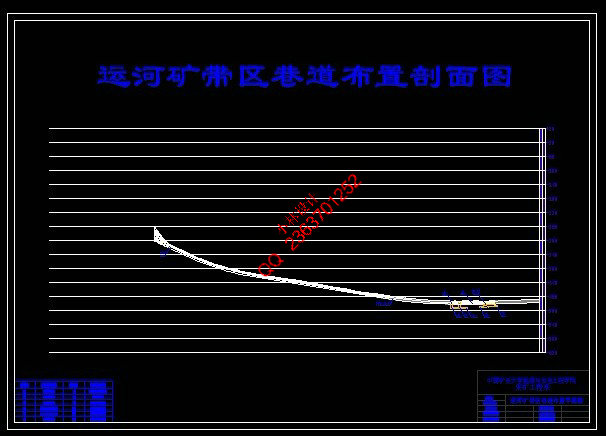

矿井采用大巷直接布置带区生产,布置一个工作面,工作面年生产能力约180万吨,工作面长180m,采煤方法为倾斜长壁放顶煤。

矿井主运输系统采用3t底卸式矿车运输,辅助运输系统采用无轨胶轮车,通风方式为中央并列式。

专题部分:三软煤层巷道锚杆支护

翻译部分:印度煤矿未来技术与设备选型展望

关键词:运河矿;立井开拓;带区;倾斜长壁;综采放顶煤;底卸式轮车;三软;锚杆支护

ABSTRACT

This design consists of three parts, the general part, the special part and the translation part.

The general part is a new design of Yunhe Mine of coal department.It has ten chapters:an outline of the mine and mine field eology, boundary and resgrves, productive capacity and service life and working area, mine field development, preparation road, coal mining method, transportation of underground, mine lifting, mine ventilation and safety, the economic and technologic index of the mine.

This Minefield lies in the special area of Jining city.The total area of the mine is 14 km2.The boundary of the mine field runs 3.5 km on north south and 4 km on westeast on average.There only is one exploring layer:No.3#, and the average thickness of the seam is 8.64 m.It is stable and flat seam. Its dip angle is from 10 to 20 degree, and is 15 degree on average.it is a low gassy mine.The coal dust has explosion in hazard. the seam has self-combustion tendency.

The productive capacity of Yunhe Mine is 1.8 million tons per year, and it’s service life is 76.1 years, two working face is used sametime in the mine.The mine only has two levels.It gets third vertical shafts: the main shaft, the subsidiary and return airflow.The first designed development level should be located at the level of -490m.The coal mining method is fully mechanized minmg to the trend with sublevel caving in roofcoal.

There is only one working face , It is used comprehensive mechanized coal face and each productive capacity is 1.8 million tons per year.The length of the longwall face is 180m.The coal is transported by The coal is transported by the single-track drop-bottom car of 3 tons and the rubber tyre car is used in the ancillary transport.The method of mine ventilation is centralized paratactie ventilation.

The special subject of the paper is about bolt support Technology in 3 soft coal lane

The translation part is about the Technology for Tomorrow and Equipment Selection

for India Coal Mines.

Keywords:Yunhe Mine; vertical shaft development; Belt zone ; longwall mining to the dip or to the rise; the rubber tyre car;3soft; bolt support.

目 录

一般设计部分

1矿区概况及井田地质特征 ……………………………………………………… 1

1.1矿区概述…………………………………………………………………1

1.2井田地质特征……………………………………………………………3

2井田境界及储量………………………………………………………19

2.1井田境界…………………………………………………………………19

2.2矿井工业储量……………………………………………………………19

2.3矿井的可采储量…………………………………………………………19

3矿井工作制度和设计生产能力………………………………………………23

3.1矿井工作制度……………………………………………………………23

3.2矿井设计生产能力………………………………………………………23

4井田开拓………………………………………………………………………24

4.1井田开拓的基本问题……………………………………………………24

4.2矿井基本巷道……………………………………………………………31

5准备方式—带区巷道布置…………………………………………………… 37

5.1煤层的地质特征…………………………………………………………37

5.2带区巷道布置及生产系统………………………………………………38

6采煤方法……………………………………………………………………43

6.1采煤工艺方式……………………………………………………………43

6.2回采巷道布置……………………………………………………………62

7井下运输………………………………………………………………………64

7.1概述………………………………………………………………………64

7.2带区运输设备的选择……………………………………………………64

7.3大巷运输设备的选择……………………………………………………65

8矿井提升………………………………………………………………………… 69

8.1概述………………………………………………………………………69

8.2主副井提升………………………………………………………………69

9矿井通风及安全 …………………………………………………………………72

9.1矿井概述…………………………………………………………………72

9.2带区及全矿所需风量…………………………………………………76

9.3全矿井巷通风阻力…………………………………………………81

9.4选择矿井通风设备…………………………………………………84

9.5矿井灾害的防治措施………………………………………………87

10矿井基本技术经济指标……………………………………………95

专题设计部分

题目:三软煤层巷道锚杆支护

1概述………………………………………………………………………………97

2煤层巷道围岩变形破坏机理分析…………………………………………………97

3三软煤层巷道支护原理………………………………………………………98

4锚杆支护、注浆加固技术…………………………………………………………100

5工程实例……………………………………………………………………100

翻译部分

英文原文…………………………………………………………………114

中文译文…………………………………………………………………126

参考文献……………………………………………………………………135

|