|

|

|

|

设计名称 |

黄石工矿集团胡家湾矿井初步设计 |

|

|

设计编号 |

W340 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

39000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

摘 要 Abstract

This design well field area is 3.9 square kilometers, the annualoutput 450,000 tons. In the well field the coal bed tax saves quitestably, the coal bed inclination angle 28, average coal thick 3.2m,the overall geological condition quite is simple, and central has thefault growth east the well field scope. The methane and the dioxide carbon content relative are not high,wells up the water volume not to be big. Carries on the well fielddevelopment and the standby mode preliminary design according to theactual geological data situation, this mine pit decided uses verticalshaft inside slope two levels mining, the design uses the demolitionto mine coal time picks entire Gao Huicai the craft, moves towards thelong wall mining coal method, with all cross falls law processing topick the depletion region. And to the mine pit transportation, the mine hoist, the mine pitdrains water and ventilates and so on each production system theequipment shaping computation, as well as sets the request to the minepit security technology measure and the environmental protection,completes the entire mine pit the preliminary design. The mine pitcompletely realizes the mechanization, uses the advanced technologyand the model has realized the high production highly effectivemodernization mine pit experience, realizes an ore high productionhighly effective mine pit thus to achieve the good economic efficiencyand the social efficiency at the same time. |

|

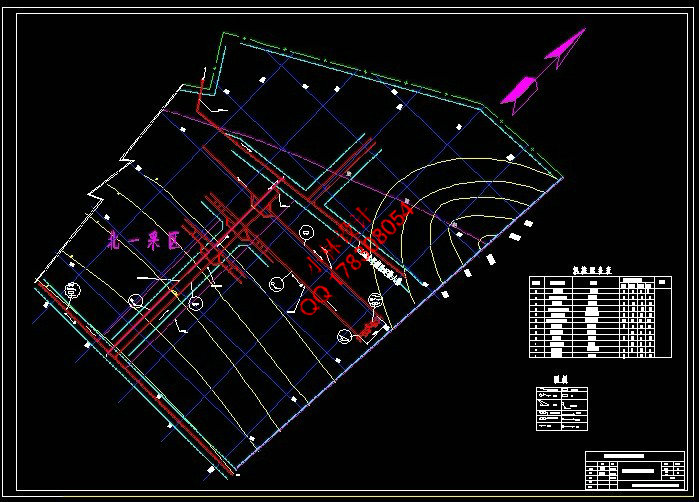

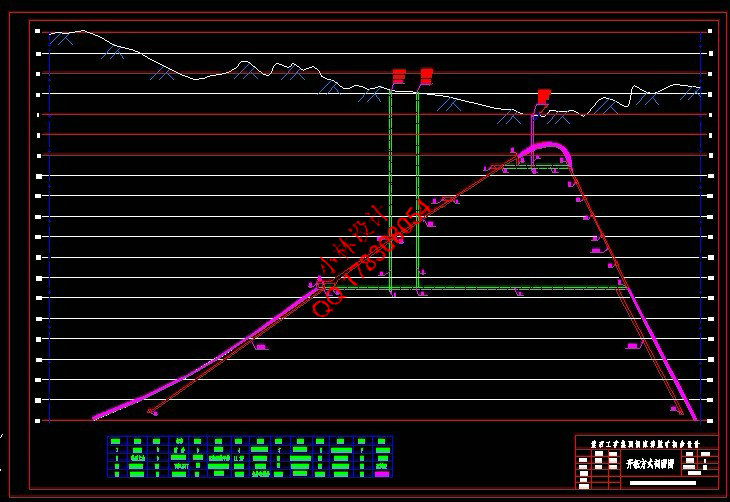

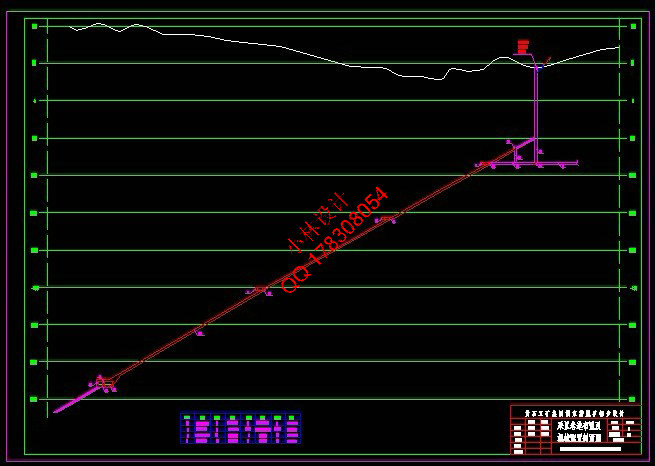

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1