|

设计简介 |

设计描述:

Word版说明书一份,33页,18000字左右.

外文翻译一份

CAD版本图纸,共10张:

摘 要

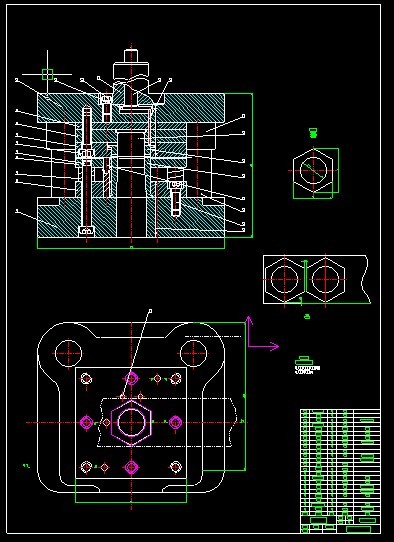

冲压模具在工业生产中应用广泛。冲压模具的设计充分利用了机械压力机的功用特点,在室温的条件下对坯件进行冲压成形,生产效率提高,经济效益显著。本零件采用的是倒装复合模冲裁,主要要涉及到冲裁件工艺的分析,排样的设计,排样方法,搭边值的计算,冲裁力的计算,模具压力中心的计算,凸模与凹模刃口尺寸的计算,模具的总体设计,主要零部件的设计,模具总装配图的绘制,压力机设备的选定。

关键词: 冲压、模具、制造

Abstract

Stamping die in industrial production in the extensive application. Stamping die design take full advantage of the characteristics of the function of mechanical press, at room temperature under conditions of the blank piece of stamping, more efficient production and significant economic benefits. Stamping die design take full advantage of the characteristics of the function of mechanical press, at room temperature under conditions of the blank piece of stamping, more efficient production and significant economic benefits. This paper describes the mold structure is simple and practical examples, easy to use and reliable, similar to parts of the mass production of certain references. In a traditional industrial production, production workers in the labour-intensive, and labor capacity, which has seriously affected the improvement of production efficiency. With today's technology development, industrial production in the mold of use has become increasingly arouse people's attention, a lot has been applied to industrial production in the past. Stamping die of automatic feed technology into actual production, stamping die can greatly increase labor productivity, reduce the burden on workers and has significance of technological progress and economic value.

Key word: punching、die、manufacture

目录

绪 言 3

1冲裁件的工艺分析 4

2冲压工艺方案的确定 5

3排样设计 5

3.1 排样方法 5

3.2.1 搭边值的确定 6

3.2.2 条料宽度的确定 7

3.3材料利用率 8

4冲裁力相关的计算 9

4.1计算冲裁力的公式 9

4.2总冲裁力、推料力、卸料力、顶件力和总冲压力 11

4.3压力机公称压力的选取 13

5模具压力中心的确定 14

6冲裁间隙 15

7凸模与凹模刃口尺寸的计算 17

7.1 刃口尺寸计算的基本原则 17

7.2 刃口尺寸计算方法 18

7.3 刃口尺寸计算 21

8 模具总体设计 22

8.1 模具类型的选择 22

8.2定位方式的选择 22

8.2.1 送进导料方式的选择 22

8.2.2 送料定距方式的选用 23

8.3 卸料、出件方式的选择 23

9主要零部件的设计 23

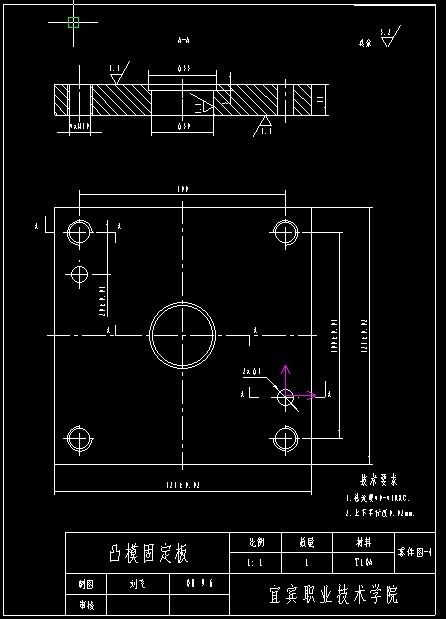

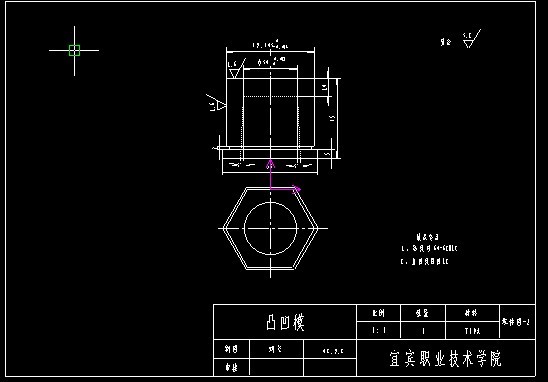

9.1工作零件的结构设计 24

9.1.1凸凹模的设计 24

9.1.2 冲孔凸模的设计 24

9.1.3 落料凹模的设计 25

9.2 卸料板的设计 27

9.3 定位零件的设计 27

9.4 模架及其它零件的设计 28

10模具总装图 29

11压力机设备的选定 29

结 论 31

致 谢 32

参考文献 33

|