|

设计简介 |

设计描述:

文档包括:

Word版说明书一份,23页,约11000字

外文翻译一份

CAD版本图纸,共22张

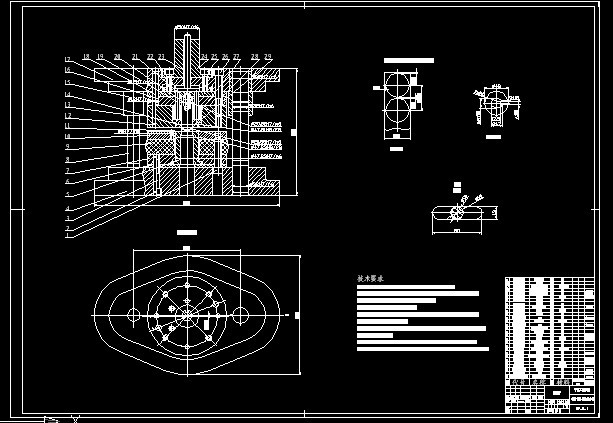

标题 锁片落料冲孔复合模

摘要:本论文根据产品图样,分析冲裁件的形状、特点、尺寸大小精度要求、表面质量及所

用材料等冲压工世性,在此基础了,根据复合模的高效、高质量等特点选用倒装的复合模,上出件,下出废料,废料直接从冲床台面孔排出,不阻塞,操作方便、安全。上模采用橡胶,起到一定的平整作用,提高工件质量,甚至减少工序。分别设计了凸凹模、凸模、凹模的结构,

凸模采用成型加工或线切割,冲裁部分进行热处理,由螺钉固定,刚性推件,弹性卸料装置

橡胶的弹性把料板由下而上推出,随上模的动作而动作,运动平稳可靠且不易损坏模具,采用中间导柱圆形有利用安装,且因安装不当而造成模具损坏,根据冲压力选择开式固定台压力机

关键词:冲裁件 复合模 设计

Abstract: The present paper basis product pattern, the analysis blanking shape, the characteristic, the size size precision request,the surface quality and use ramming labor world and so on the material, in this foundation, according to the superposable die the superposable die which was highly effective, high grade and so on the characteristic selects inverts, on, got down the waste material, the waste material discharges directly from the punch press Taiwan face,did not block, ease of operation, security. The top die uses the rubber, plays to the certain smooth role, improves the work piece quality, even reduces the working procedure. Has designed the convex-concave mold, the raised mold, the concave mold structure separately, the raised mold uses takes shape the processing or the line cuts, the blanking partially carries on the heat treatment, by the screw retention, the rigidity pushes, the elastic dumping device rubber elasticity from bootom to top promotes the yard lumber, but acts along with the top die movement, the movement steady reliable also is not easy to damage the mold among, uses the guide pillar circular to have the use installment, also because of does not install when but creates the mold damage, according to flushes the pressure to choose the type fixed platform press.

Key word: Blanking superposable die design.

目录

1 前言 ……………………………………………………………………………. 3

2 冲裁件的工艺性分析 ………………………………………………………….. 4

3 冲裁的工艺方案 ……………………………………………………………….. 5

4 排样設計与计算 ……………………………………………………………….. 5

4.1排样方法和原则 ……………………………………………………………………….. 5

4.2确定搭边值 ……………………………………………………………………………. 5

4.3送料步距与条料宽度的计算 …………………………………………………………… 6

4.4材料利用率的计算 ……………………………………………………………. 7

5 冲裁力计算 ……………………………………………………………………. 8

5.1落料力、冲孔力、卸料力、推件力的计算 …………………………………….. 9

5.2初选压力机 …………………………………………………………………… 10

6 模具压力中心 ………………………………………………………………….. 10

7 凸凹模的设计 ………………………………………………………………….. 12

7.1尺寸计算原则 ……………………………………………………………………………. 12

7.2落料凸、凹模刃口尺寸计算 ………………………………………………………….. 12

7.3冲孔凸、凹模刃口尺寸计算 ………………………………………………………….. 13

7.4凹模的高度与强度校核 ……………………………………………………………….. 14

7.5凸模、凸凹模的强度校核 …………………………………………………………….. 14

8 凸模垫板承压计算 …….…………………………………………………………………. 18

9 橡胶的选用与校核 …………………………………………………………….. 18

10 模架的选用 ………………………………………………………….………… 20

11 冲压设备的选用 ……………………………………………………………….. 21

12 结束语 ………………………………………………………………………….. 21

致谢 ………………………………………………………………………………….. 21

参考文献 …………………………………………………………………………….. 21

|