|

设计描述:

文档包括:

Word版说明书一份,共30页,约17000字

CAD版本图纸,共13张:

目 录

摘要 ……………………………………………………………………………… 3

1. 前言 …………………………………………………………………………… 4

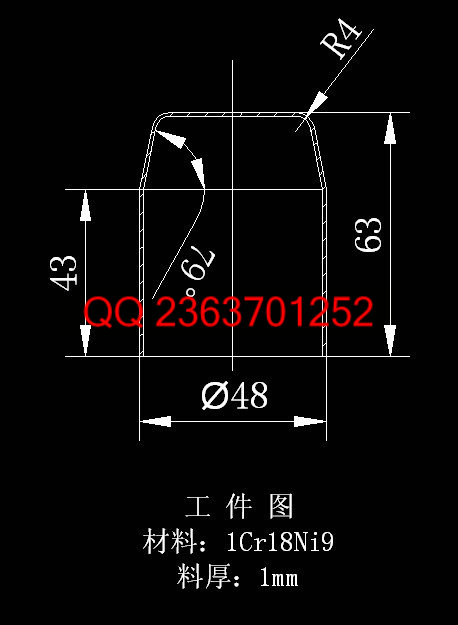

2. 零件的工艺性分析 …………………………………………………………… 5

3.零件冲压工艺方案的确定 …………………………………………………… 6

3.1 计算毛坯尺寸 …………………………………………………………… 6

3.2 计算拉深次数 …………………………………………………………… 8

3.3 确定工序的合并与工序顺序 …………………………………………… 9

4.主要工艺参数的计算 ………………………………………………………… 10

4.1确定排样、裁板方案 …………………………………………………… 10

4.2 确定各中间工序尺寸 ………………………………………………… 11

4.3计算各工序压力、选用压力机 …………………………………………… 12

5. 编写冲压工艺过程卡片 …………………………………………………… 14

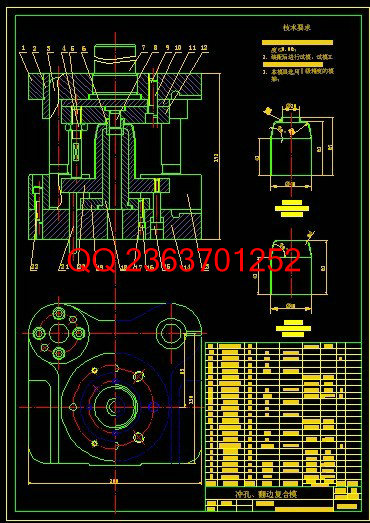

6. 落料、拉深复合模具的设计 ……………………………………………… 17

6.1 模具结构形式选择 ……………………………………………………… 17

6.2 模具工作部分的设计 …………………………………………………… 18

6.3 模具其它零件的设计与计算 …………………………………………… 21

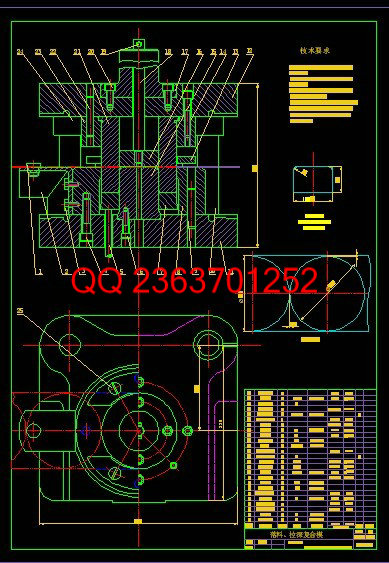

7. 再次拉深模具的设计……………………………………………………… 22

7.1 模具结构形式选择……………………………………………………… 22

7.2 拉深凸模和凹模工作部分的设计 ………………………………………… 23

7.3 模架的选用 ………………………………………………………………… 24

7.4 压力机的校核 ……………………………………………………………… 25

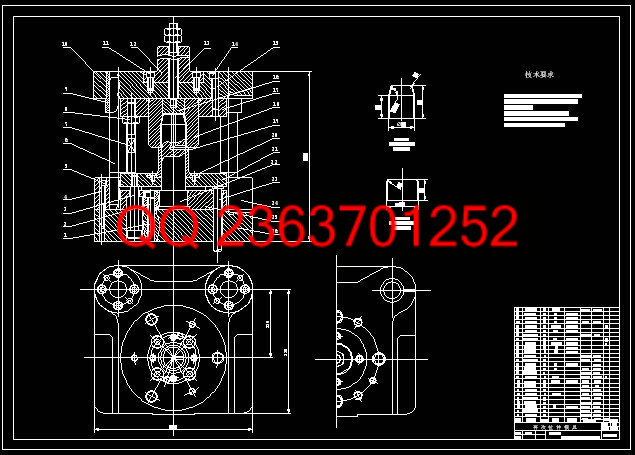

8. 冲孔、翻边复合模具的设计 ………………………………………………… 25

8.1 模具结构形式选择 ………………………………………………………… 25

8.2 冲孔、翻边复合模具工作部分的设计………………………………………26

8.3 模架的选用 ………………………………………………………………… 27

8.4 压力机的校核…………………………………………………………………28

结论 …………………………………………………………………………… 28

总结与体会 ……………………………………………………………………… 29

致谢词 …………………………………………………………………………… 29

参考文献…………………………………………………………………………… 30

摘 要

从锥形油杯的冲压工艺分析入手,针对它的结构特点,详细分析了其成形工艺性,制定出切实可行的工艺方案,采用较简单的模具结构,生产出了合格的产品。详细介绍了落料、拉深复合模具,再次拉深模具和冲孔、翻边复合模具等的模具结构的设计过程。并包括各个工序的顺序及确定工序件尺寸。冲压模具的设计首先是要从冲压工艺方面对所要设计的锥形油杯进行分析与计算,接着在分析与计算的基础上,参看相关的冲压设计资料,从而确定冲压工艺方案,再在此基础上考虑各工序的复合,最后进入冲压模具具体结构的设计。在此基础上对各副冲压模具的主要零部件的尺寸进行设计与计算,期间要参考大量与冲压相关的资料和翻阅各种《冲压手册》,并通过计算以确定各副模具具体的结构及尺寸,通过不断的计算与修改,冲压工序的选择是经查阅相关资料和对工件形状仔细分析的基础上进行的;冲压模具的选择是在综合考虑了经济性、零件的冲压工艺性以及复杂程度等诸多因素的基础上进行的;产品毛坯展开尺寸的计算是在方便计算但不影响模具成型的前提下简化为所熟悉的模型进行的。文中还对冲压模具成型零件和其他相关零件的选择原则及选择方法进行了说明。

【关键词】油杯、模具设计、拉深、冲压工艺、毛坯展开尺寸

Abstract

On the basis of the analysis of the compressor grease cup with taper’s structure and regarding the structure characteristics of the grease cup, the processor forming the grease cup is analyzed in detail. A practical technological process has been worked out. Relatively simple structures of the dies have been designed and qualified parts have been manufactured with dies. The design and manufacture for the compound tools of blanking and drawing is introduced in detail. The second drawing die and a compound tools of pierce and trim are also introduced,including determination of the operation sequence and operation parts’ dimensions. The first thing to design the compress dies is the analysis and lots of calculation for the grease cup with taper on basis of stamping technological process. The election of press process is based on consulting correlation datum and analyzing the form of manufactured product meticulous; The election of press die is based on synthesis considerations on economical efficiency、the processing property of part and complex degree are many factors; Calculating the work blank of manufactured product unfold dimension is lined feed on the premise of calculation convenience but without contribution die confectioning simplified frequent application cast. In the text ,to introduce the election principle and means of press confectioning art and miscellaneous rapport part, otherwise also introducing calculation means on the work blank form of many kinds of product unfold dimension and simplified cast, and the means of looking up on the reference books of designing press die .

【Key words】grease cup, die design, drawing, stamping technological process,

The unfold dimension of the work blank

|