|

|

|

|

设计名称 |

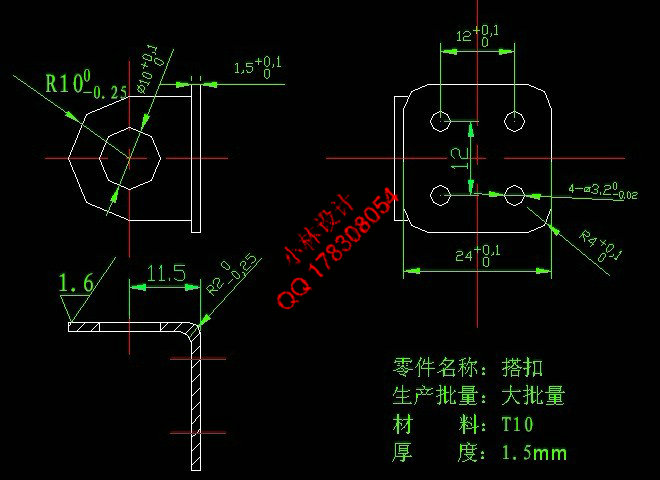

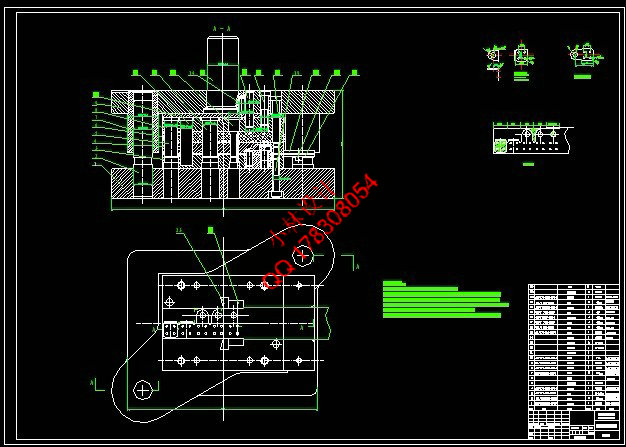

搭扣冲压工艺及其模具设计[四工序级进模] |

|

|

设计编号 |

W217 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

14000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括: CAD版本图纸,共14张 目 录

摘要.....................................................................1

...17

.........18 搭扣冲压工艺及其模具设计 摘 要:本文设计的是搭扣的冲压工艺分析和模具的具体结构设计。通过对搭扣的工艺性分析,选择符合于给 定条件的最优工艺方案,如:选择基本工序,确定其顺序,工序数目及工序组合形式。然后以此为基础,设计 出冲压模具主要零件的结构。结合实际,进行合理、正确的规划。在设计中,介绍了零件的排样图、定位设计 、冲裁力的计算和压力中心的计算。在详细分析搭扣零件工艺的基础上,设计出了级进模这套模具,并详细介

绍了级进模模具的结构和主要零件。 Design of Hasp Stamping Craft and Mold Abstract: The design focus on both the analysis of Pessing technics of the hasp and the particular configuration design of die. It is based on the technical analysis of the branch nog on the Pendulum to choose a best craft procedure.For instance, basic procedure’s choosing ,basic procedure’s sequence confirmatio,the amount of the working procedure and the format of the procedure combination.After the steps upward, then it start the design of the main part of the pressing die.Relate with the practice to make the reasonable and correct layout.It’s presented on the design regarding the part sampleing makeup ,orientation design,calculation of puch forch and center pressing.Again,the design of the progressive die is based on the particular analysis of the part craft of the hasp.The main parts and configurations of the design have described on the paper in detail. Key words: stamping ; mold design ; blanking ; hasp |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!