|

|

|

|

设计名称 |

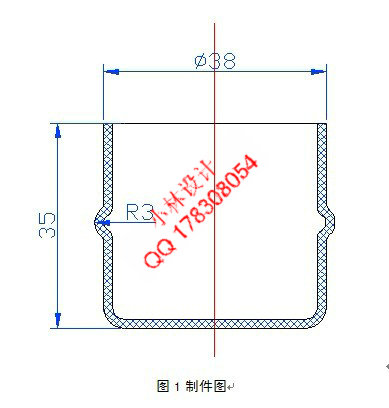

凸肚杯零件冲压工艺与模具设计-胀形模 |

|

|

设计编号 |

W306 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

7400字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

word设计说明书一份,共23页,约7400字

开题报告一份

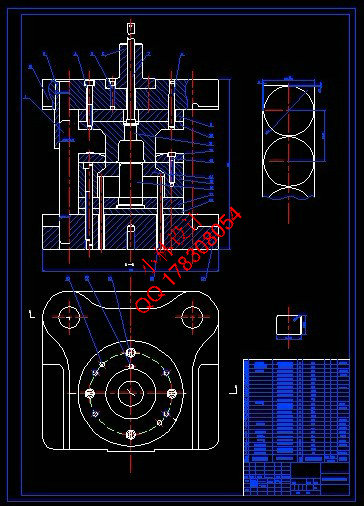

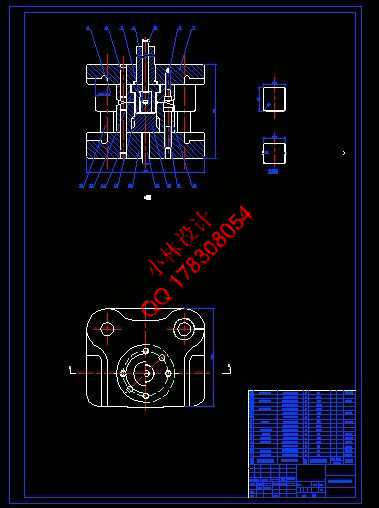

CAD版本图纸,共11张

凸肚杯零件冲压工艺与模具设计

摘要:概述冲压形成与模具技术,阐述了冲压技术的现状及发展动态。分析零件的特点,计算冲压件主要工艺参数,确定工序组合形式及模具类型和结构型式。对排样进行设计,计算工序压力,对模具主要零件和结构进行详细设计。

关键词:冲压工艺;模具设计;排样设计

Design of Stamping Process and Mold for Convex Cup

Abstract:The stamping process and mold techingnes,presentsitation and progressing dynamics are described briefly in this article. Analysis component features,Calculate the stamp out a major technology.Working group to determine the form of moulds and structural pattern.To chop them to design,The process pressure,To mold the main parts in the detailed design and structure.

Key words: Stamp process; mold design; row sample design

目 录

摘要............................................................1

关键词..........................................................1

1前言...........................................................1

1.1本设计研究的目的和意义.......................................1

1.2冲压成形与模具技术概述....................................3

1.2.1冲压的概念、特点及应用..............................3

1.2.2冲压技术的现状及发展动态............................4

2工艺分析与模具设计.............................................6

2.1准备工作.................................................6

2.2.2零件结构...........................................7

2.2冲压件主要工艺参数计算...................................7

2.3毛坯尺寸的计算并确定修边余量与拉伸次数...................7

2.3.1冲压工艺方案与模具结构类型.........................9

2.3.2排样设计..........................................10

2.3.3计算工序压力......................................10

2.4主要工作部分尺寸计算与选择..............................11

2.4.1落料-拉伸复合模工作部分尺寸的计算.................11

2.4.2落料刃口尺寸的计算................................11

2.4.3胀形模工作部分尺寸的计算..........................12

2.5模具主要零件和结构设计..................................12

2.5.1 落料-拉伸复合模工作部分尺寸的计算.................12

2.5.2 胀形模工作部分尺寸的计算..........................16

2.6模架总装图..............................................20

参考文献........................................................21

致谢............................................................22

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!