|

|

|

|

设计名称 |

轴加工工艺规程及铣方块的夹具设计 |

|

|

设计编号 |

J2-A0154 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

16000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

说明书一份,31页,约16000字

摘要……………………………………………………………1

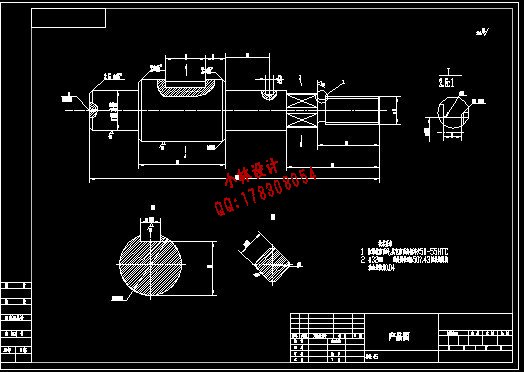

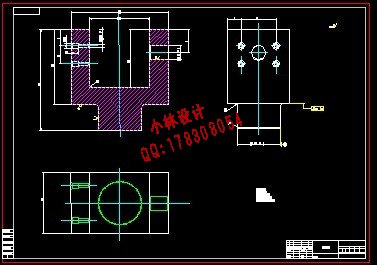

首先,本人设计的零件为轴,它的作用是起到传动作用,传动力的方向和轴力。轴的样式很多,应用的也很广泛,不过本人对于自己设计的轴经过了解,根据零件的形状、尺寸精度、生产的经济效益等各方面的详细分析其加工工艺,采用多工序,机床加工。通过对零件的分析,此轴要求精度高,工序适当集中,要求光滑,所以选用的工具和尺寸要量得准。对轴的夹具设计也要求也高,因为精度和公差要求高,表面更要采用磨床磨削。最后对零件进行校核。以便达到零件精度的要求。 关键词:传动作用、轴力、广泛、工序、磨床、夹具、校核、

Output shaft design Abstract : First, I designed components for the shaft, and its role is to drive, Chuan dynamic direction and axial force. Axis of many forms, the application is very extensive, but I own design for the shaft through understanding, under parts of the shape, dimensional accuracy, cost-effective production areas such as a detailed analysis of its manufacturing processes, multi-process, machine processing. Part of the analysis, accuracy of this axis, the appropriate concentration processes require smooth, So use the tools and size to measure the potential. On the shaft fixture design requirements, because accuracy and tolerance, to use more surface grinder drilled. Finally, the parts are checked. To meet the requirements of precision parts. Keyword : transmission, axle, extensive, processes, machines, fixture, Verification |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1