|

|

|

|

设计名称 |

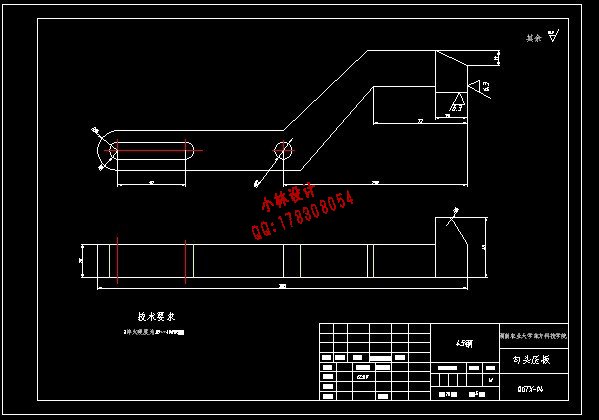

4125型柴油机气缸体的机械加工工艺及夹具设计 |

|

|

设计编号 |

B171 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

16000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

工艺卡一套

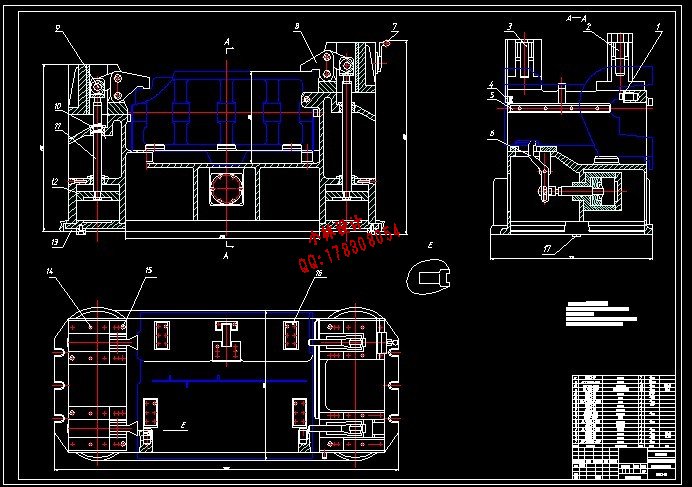

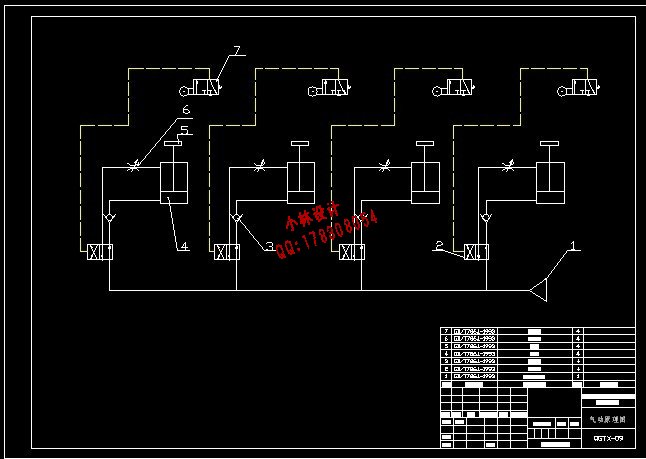

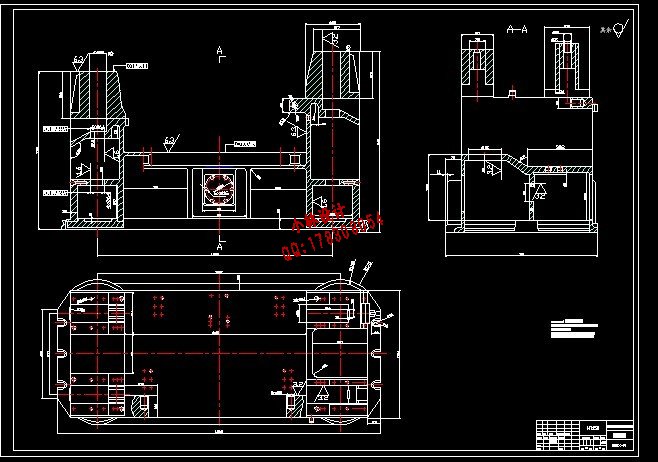

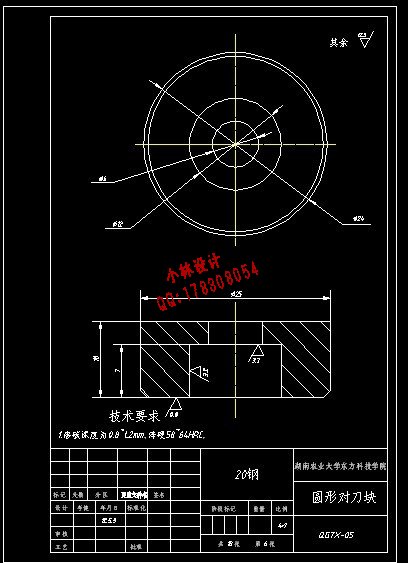

摘 要:本课题是对4125型柴油机气缸体进行工艺设计和夹具的设计。对气缸体的主要加工表面、气缸体顶面、主轴承座侧面、气缸孔、主轴承孔及凸轮轴承孔等的工艺规程进行了详细的分析,填写了工艺过程卡片及工序卡片,设计了粗铣气缸体平面专用机床夹具。在对此气缸体的工艺设计中为减少箱体在加工过程中的误差,我们考虑基准的重合原则,统一原则,互为基准原则以及粗基准的选择原则,为使定位稳定夹紧可靠,要求所选用的粗基准尽可能不重复使用原则。夹具的设计,保证了零件的加工精度,同时提高了生产效率,降低了工人的劳动强度。

Abstract: This topic is for 4125 diesel engine cylinder block process design and fixture design. The main processing of the cylinder block surface, the cylinder block end face, Lord side, cylinder bearing holes, the main bearing hole and CAM bearing hole and techniques procedure are analyzed in detail, and fill out the process card and process card, design the rough milling cylinder block plane special machine tool fixtures. This cylinder block in the process design to reduce the error in the process, we consider the benchmark superposition principle, unified principle, thus the principles and the benchmark crude benchmark the choosing principle, positioning for stable clamping reliable, request chooses not to repeat the benchmark crude as far as possible, use the principle.The fixture design ensure the parts processing precision, While improving production efficiency and reduce the labor intensity of the workers.

摘要…………………………………………………………………………………………1 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1