|

设计简介 |

设计描述:

文档包括:

Word说明书1份,共24页,约10000字

CAD版本图纸,共27张

目录

前言…………………………………………………...............

目录

摘要……………………………………………………..………

一、机床夹具概述……………………………………………

(一)机床夹具…………………………………………………

(二)机床夹具的功能…………………………………………

(三)机床夹具在机械加工中的作用……………………………

(四)机床夹具的发展趋势………………………………………

二、 零件的分析……………………………………………

(一)零件的作用………………………………………………..

(二)零件的工艺分析…………………………………………..

三、确定毛坯图……………………………………………..

四、工艺规程设计 …………………………………………

(一)定位基准的选择……………………………………………

(二)制订工艺路线……………………………………………..

(三)选择加工设备及刀具、夹具、量具……………..............

(四)加工工序设计……………………………………...............

五、填写机械加工艺过程卡和机械加工工序卡…………..

六、夹具设计………………………………………………..

七、参考文献…………………………………………………

前言

本次设计是为毕业答辩而准备的。大学课程已全部结束,此次设计要把大学期间学的东西综合运用,使我们学的东西融会贯通,并结合生产实习中学到的实践知识独立地分析和解决工艺问题。

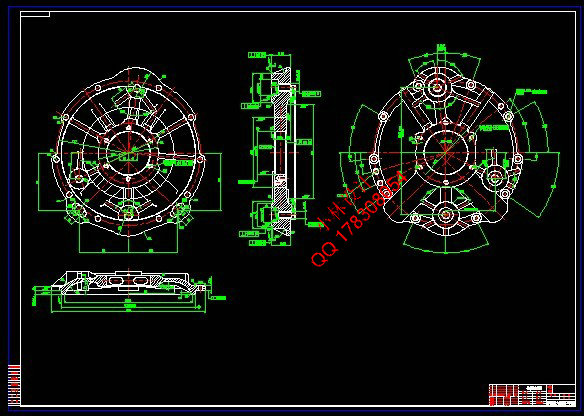

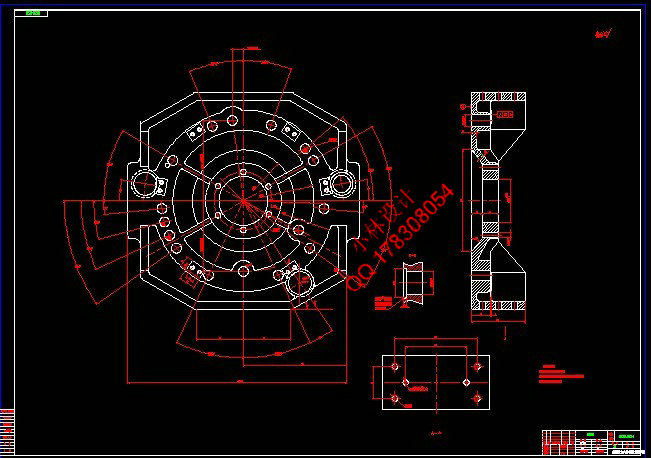

本次设计传动机盖板。内容涉及到零件分析、确定毛坯、拟订工艺、工序设计以及两套夹具设计。此次设计把我们大学期间学的大部分内容都用上了,还用到了其它有关手册和图表。这次设计是在学校的最后一次设计,它是一次很好的锻炼机会,为我们未来从事的工作打下良好的基础。

由于能力有限,经验不足,设计中有许多不足之处,希望各位老师多加指教。

摘要

在机械工业中,产品由于在质量、效能和可靠性等方面有很高的要求,而且构造特点一般表现为形状复杂、壁薄、刚度低、技术要求高等。因此,对它的制造与工艺就显得非常具有挑战性和严格性。

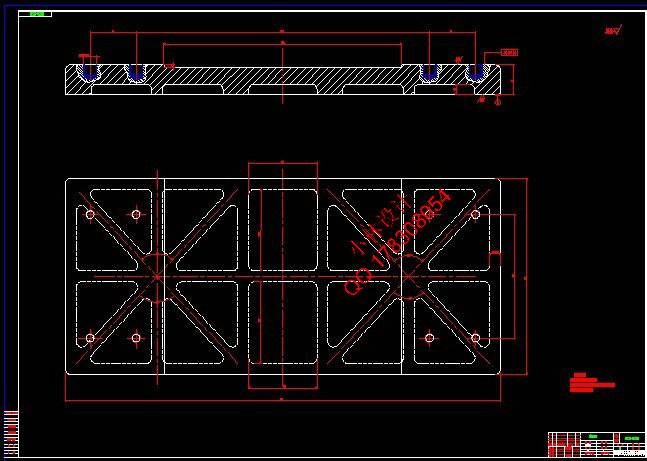

本次设计是针对阀导承的制造与工艺, 详细地介绍了该产品的整个加工方案的拟订过程,并针对其中钻孔的工序所需的专用夹具进行了设计。工艺设计中依据现有的条件,仍选用传统的机械加工方式进行编制,但又根据零件斜孔特点及其结构性能的要求,部分按照非常规的加工路线进行加工,更好的确保了产品的质量和技术性能要求,也体现产品的加工特点。另外,在专用夹具的设计中,采用了螺栓联接式夹具体,与传统的焊接式相比,虽然成本略有提高,但更利于夹具以后更换、维修,提高了材料的利用率。此外为次道工序所加工的孔设计的夹具还要考虑到加工的孔是斜孔,夹具还要保证其与水平面的夹角,这也增加了夹具设计的难度。

关键词: 工艺 工序 专用夹具

Abstract

In the machinery industry, the products in the quality, performance and reliability requirements are high, and constructed for the general performance characteristics of the shape of complex, thin-walled, low stiffness, high technical requirements. Therefore, the manufacturing and process it becomes very challenging and rigorous nature.

The design is for the valve guide for the manufacturing and technology, detailed description of the product throughout the course of processing programs, and procedures for which required a special fixture designed. Process design based on existing conditions, still choose the traditional approach to the preparation of machining, but in accordance with the characteristics of parts and the structure of their own performance requirements, some of the processing in accordance with the non-conventional processing routes and better ensure that the products quality and technical performance requirements, but also the characteristics of their products. In addition, the dedicated fixture design, the use of the bolt-type connection specific folder, and compared to traditional welded, although slightly higher cost, but it is more beneficial after the replacement of fixtures, maintenance, improve the utilization of the material. In addition to the processing procedure at the hole of the fixture design must take into account the processing of the hole is the slant-hole, jig also its angle with the horizontal plane, which also increased the difficulty of fixture design.

Key words: Process process dedicated fixture

|