|

|

|

|

设计名称 |

两级减速箱体工艺工装设计-2套夹具 |

|

|

设计编号 |

V084 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

17000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

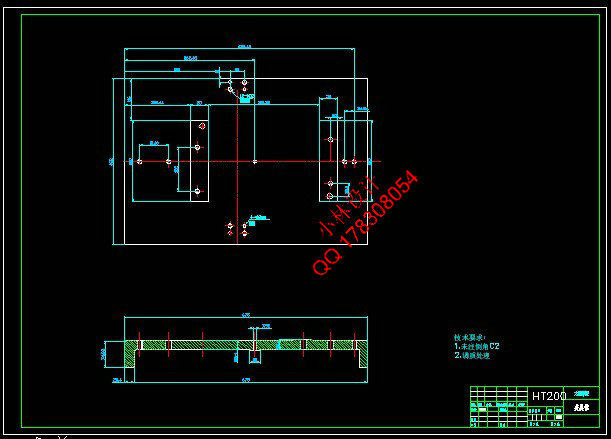

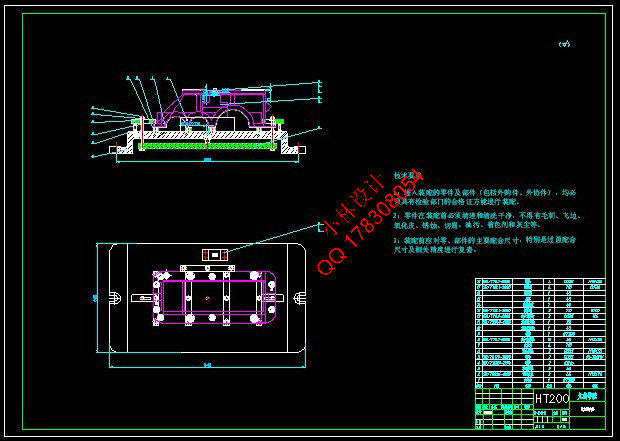

文档包括: CAD版本图纸,共9张

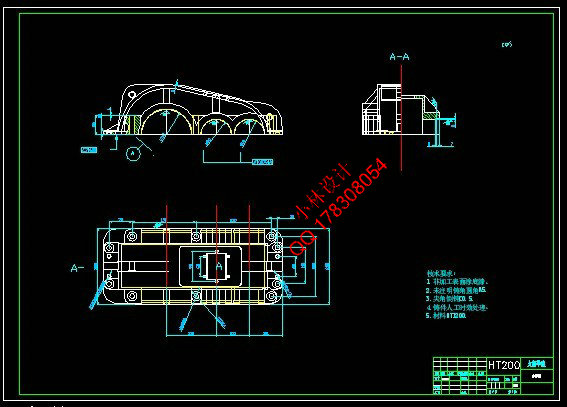

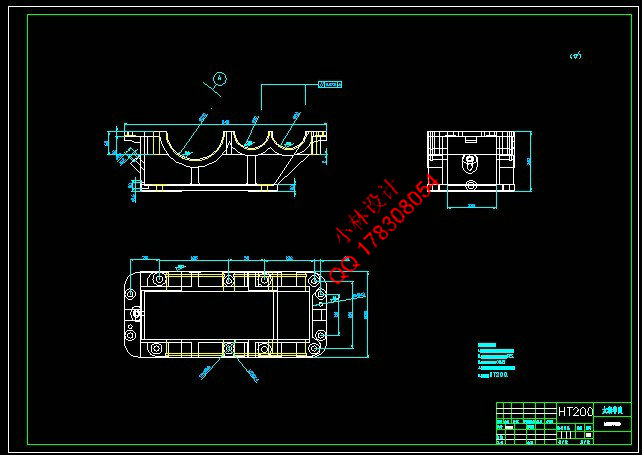

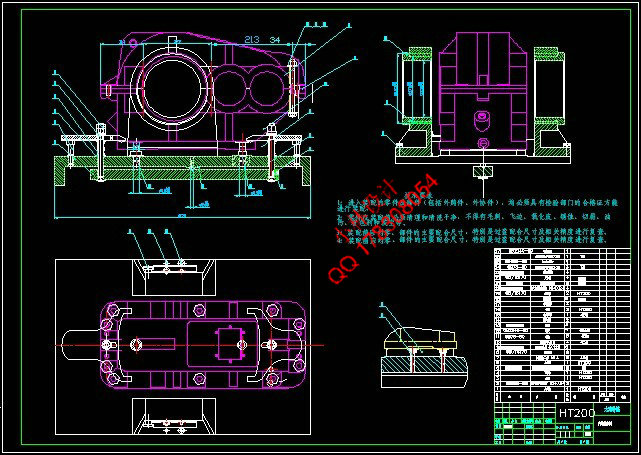

,降低劳动强度,精镗镗轴轴承孔的组合和专用夹具设计。本设计说明书可分为三部分:

并制定工艺路线,确定机械加工余量,工序尺寸及切削用量等。 保准确性,选择卧式镗双面非刚性轴组合。并绘制了加工工序图,加工示意图和卧式单面组合镗床的尺寸联系

图。 夹紧力,确保可以加工。 关键词:箱体、加工工艺、夹具

Abstract reasonable or unreasonable, it directly relates to the quality requirements could eventually parts, The design of fixture is big, it is the indispensable part in relation to improve the efficiency of the machining. So both in mechanical processing industry is crucial link. The graduation design, the topic is I design process and fixture enclosure reducer design. This case is complex, volume parts structure. In order to improve production efficiency and reduce labor

intensity, I design a drill fixture. The design manual is divided into three parts: process, contents and procedure, mechanical manufacturing process planning of the type and the procedure formats, introduced the principle and procedure. The choice of the locating datum, the process route in the selection of surface machining method, the method of processing, sequence

arrangement has been introduced in detail. for determination of casting billet, The timeliness, The preparation process route and the process of writing (card), whole process card technology in processing after inspection. In the process of calculation, and fixture design of mechanical concise manual of gb through alignment. Under the limitation in the economic guarantee processing request. Key words: box, processing technology, process,fixture

目 录 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1