|

设计简介 |

设计描述:

文档包括:

word说明书一份,共34页,约15000字

任务书一份

开题报告一份

外文翻译一份

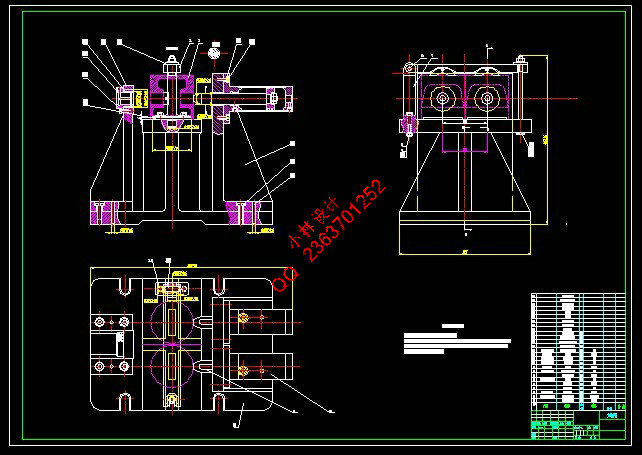

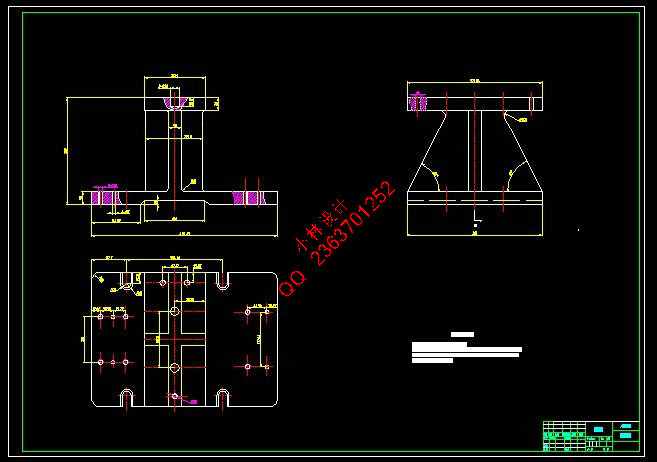

CAD版本图纸,共5张

摘 要

机械制造技术基础课程设计是我们在学完了大学的全部基础课、专业基础课以及专业课后进行的。这是我们在进行毕业设计之前对所学的各科课程一次深入的综合性总复习,也是一次理论联系实际的训练。因此,他在我们的大学四年生活中占有重要的地位。

我这次的课题是镗销孔活塞零件专用夹具的设计,有活塞零件图、毛坯图、夹具装配图、夹具零件图各一张以及非标零件图五张,机械加工工艺过程卡片和与所设计夹具对应那道工序的工序卡若干张。首先我们要熟悉零件,题目所给的零件是汽车活塞。了解了活塞的作用,接下来根据零件的性质和零件图上各端面的粗糙度确定毛坯的尺寸和机械加工余量。然后我们再根据定位基准先确定精基准,后确定粗基准,最后拟定活塞的工艺路线图,制定该工件的夹紧方案,画出夹具装配图。

就我个人而言,我希望通过这次课程设计对自己未来将从事的工作进一步适应性的训练,希望自己在设计中能锻炼自己的分析问题、解决问题、查资料的能力 ,为以后的工作打下良好的基础。

由于能力有限,设计尚有很多不足之处,希望各位老师给予指导。

关键词:夹具;活塞;零件图;

Abstract

Machinofacture technology curriculum design is that we mimic all basic courses , technology basic course and major part having completed university being in progress after the specialized course. This is that we always review before the graduation practice being in progress to what be learned every thorough comprehensiveness of course,be also that a theory contacts actual training , it occupies important position therefore, in our university for four years life.

Abstract with the pin hole boring piston parts special fixture design, piston parts diagram, blank map,jig assembly drawing, fixture parts each piece and non-standard parts of figure five. Machining process with the card and the corresponding fixture designed by the procedures of the process of several card. First of all, we must familiar with the parts, subject to the parts is piston understanding of the role, followed in accordance with the nature of parts and components in the face of the map on the roughness of rough determine the size and mechanical Jiagongyuliang. According to another location and then we set the benchmark fine first base, established after the benchmark crude, piston finalizing the road map process, the enactment of the workpiece clamping programme, to draw fixture assembly.

For me personally, I hope that through the curriculum design of their future will be further engaged in the work of adaptive training, in the hope that their design can exercise their own analysis, problem solving, the ability to search information, the work laid for the future A good foundation.

Because of limited capacity, there are a lot of design deficiencies, I hope that teachers give guidance.

Key words:fixture;piston;part drawing;

目 录

年 月 日 II

摘 要 III

Abstract IV

1绪 论 1

1.1 本课题的研究内容和意义 1

1.2 国内外的发展概况 1

1.3 本课题应达到的要求 1

2零件的分析 2

2.1 活塞的作用 2

2.2 活塞的结构组成 2

2.3 活塞的主要技术条件分析 3

3 零件的工艺规程设计 4

3.1确定零件的生产纲领 4

3.2 确定毛坯的材料和制造形式 4

3.2.1 毛坯的材料选择 4

3.2.2 毛坯的制造方法 4

3.3 定位基准的选择 4

3.3.1 粗基准的选择 5

3.3.2 精基准的选择 5

3.4 制定工艺路线 6

3.5 活塞毛坯尺寸、加工余量、工序尺寸的确定 8

3.5.1 活塞毛坯尺寸的确定 8

3.6确定切削用量及工时定额 9

3.6.5 止口的切削用量 16

4.1 机床夹具的作用及组成 18

4.2 机床夹具设计过程 18

4.3 夹具的初步设计方案 18

4.4定位方案设计 19

4.4.1 定位元件选择 19

4.4.2 定位误差的分析与计算 19

4.4.3 液压缸的设计 20

4.5夹紧方案设计 21

4.5.1 夹紧元件的选取 21

4.5.2 夹紧力的分析与计算 22

4.5.3 原动力计算 22

5 结论与展望 24

5.1 结论 24

5.2 不足之处及未来展望 24

致 谢 25

参考文献 26

|