|

|

|

|

设计名称 |

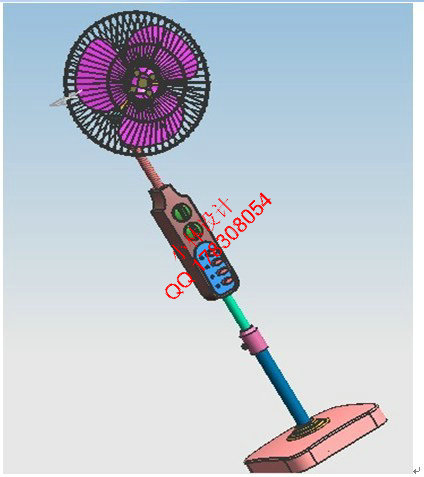

基于UG的家电电风扇造型设计及动态仿真[UG三维] |

|

|

设计编号 |

V108 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

21000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

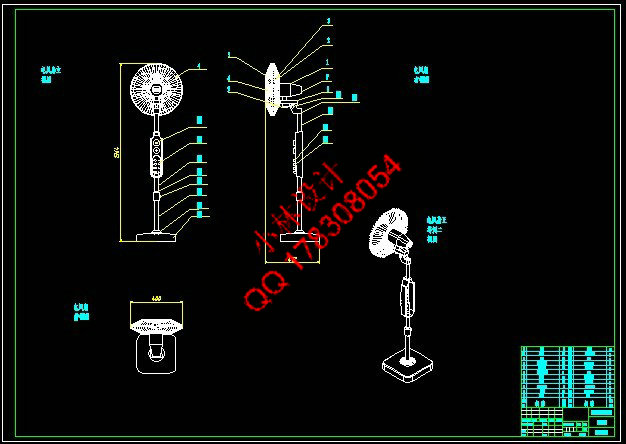

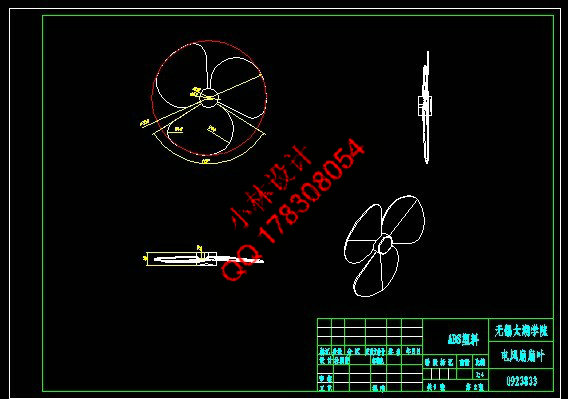

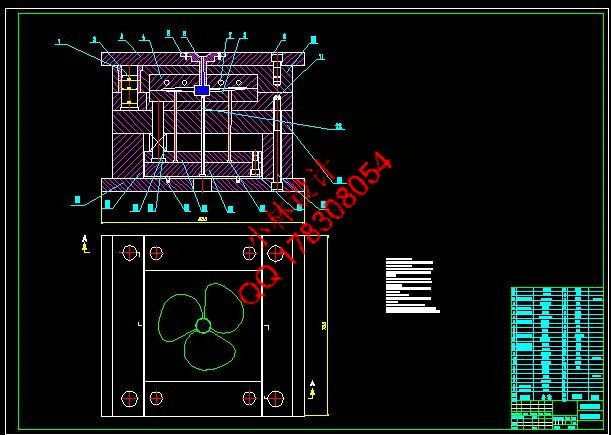

CAD版本图纸,共10张

面对激烈的市场竞争,制造业必须加速产品开发进程,缩短设计开发周期。计算机技术和计算机图形学的不断 发展,为人们提供了强有力的工具,三维CAD/CAM/CAE集成化软件被广泛应用于制造业。与传统的装配设计相比 ,虚拟装配技术能满足并行工程的要求,实现产品可装配的设计,及时发现产品设计中的问题,提高装配质量

和装配效果。 软件设计非常困难,UG可以轻松解决这个问题,UG软件具有很强大的实体造型、曲面造型、虚拟产品装配仿真 、工程图生成等功能。论文以从实物到模具的逆向设计过程论述了风扇虚拟设计中的关键环节,即零部件建模 、虚拟装配、动态仿真和扇叶的注塑模设计等。并对产品设计中的虚拟设计方法与传统设计方法的差异、优越 性进行了比对。通过可视化显示装配、干涉分析然后以求达到准确运动仿真,使生产真正在高效、高质量、低 成本的环境下完成。

关键词:三维造型设计;虚拟装配;运动仿真 Facing with the competitive market, manufacturers need to accelerate product development process, shorten the product design and development cycle. The continuous development of computer technology and computer graphics provides powerful tools for people, three-dimensional CAD/CAM/CAE integration software is widely used in manufacturing. Compared with the traditional assembly design, virtual assembly technology to meet the requirements of concurrent engineering, the design of their products can be equipped with timely detection of problems in product design,

improve the assembly quality and assembly efficiency. design. The shape structure of vertical electric fan is very complex, if using the traditional CAD drawing software to design will be very difficult, UG can easily solve this problem, the UG software has powerful functions of solid modeling, surface modeling, virtual assembly simulation, engineering drawing and others. This paper discussed the key link of fan that using reversal design progress from the physical to the mold in virtual design, as the part modeling, virtual assembly, dynamic simulation and the fan injection mold design. The paper also compared the advantages and differences between virtual for product design in the development of traditional design methods. Through the visual display assembly, interference analysis then to achieve accurate simulation campaign that produce real in high efficiency, high quality, short time, low cost environment.

Key words: 3D modeling design; simulation assembly; movement simulation |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1