|

设计描述:

文档包括:

word说明书一份,共40页,约13000字

任务书一份

开题报告一份

外文翻译一份

CAD版本图纸,共9张

摘 要

齿轮罩盖目前是一种普遍的机械装置,应用于大批量生产领域,具有相当大的作用,主要是起到对产品的一个保护作用,可以避免杂质进入机械,也对操作者的安全有极大的保护,所以罩盖的设计要求还是很高的!

本文就是社会生产的实际需要提出的设计题目,罩盖的设计是要根据你所要配置的机械设备的尺寸,这里加工的前端齿轮罩盖外形不是规整的,我们通过数控铣床还是比较容易加工的,在编程的过程中弧形指令用的多一点。加工小孔只需要选择对应的麻花钻,有的需要攻丝,大孔我们需要在镗床上进行加工!

本文在夹具设计上还是费了时间的,由于我们的零件是薄壁零件,外形不规则,所以增加了夹具设计的难度,我们第一个选择的是通过一个大孔的夹紧定位,采用的一面俩銷,这也是常用的定位方式,由于我们粗糙度要求不高,这样的定位可以满足我们的加工。一套夹具是不能够很好的加工的,所以我们还做了一副铣床上的第二副夹具,便于加工出更精准的零件!

最后希望此次设计的夹具能达到预期的设计要求,并能在实际的应用中取得良好的效果。

关键词:铣床;镗床;钻孔;夹具;

Abstract

Gear cover cap is a kind of general machinery, applied in mass production, have considerable effect, mainly play a protective role of products! It can avoid impurities into the machinery, and it can protect the operator safety greatly. So the design of the cover cap requirement is very high!

This paper is to design topic, put forward by the production of the practical need of society! Lid is designed according to you to configure the size of the mechanical equipment. This processing and the front end of the gear cover cap is not neat appearance. But we are easy to processing by CNC milling machine . In the process of programming arc command with a little more. Processing holes only need to select the corresponding twist drill, some need to tapping.But big holes we need on the boring machine for processing!

This article on the fixture design still had time. As a result of our parts are thin-walled parts and it has irregular shape. So increasing the difficulty of fixture design. We are the first choice is through a clamping positioning hole and use one side of the two pins. This is also a common way of clamping, due to our roughness requirement is not high. So it’s positioning can meet our processing. A set of fixture is not able to very good processing, so we also adopt the hydraulic system drives the second fixture, it’s easy to work out more accurate parts!

Last hope the design of the fixture can achieve the desired design requirements, and can achieve good effect in practical application.

Key words: milling machine; boring machine; drilling; fixture;

目 录

摘 要 III

ABSTRACT IV

1 绪论 1

1.1本课题的研究内容和意义 1

1.2国内外的发展概况 1

1.3本课题应达到的要求 1

2 分析零件 3

2.1 零件作用 3

2.2 零件结构分析 3

2.3 零件技术要求分析 3

2.4 零件的三维造型 4

3 确定毛坯零件类型 7

3.1 毛坯选择 7

3.2 铸件加工余量 7

4 拟定工艺路线 8

4.1 零件表面孔加工方法 8

4.2 工序的合理组合 8

4.2 加工顺序的选择 8

4.3 确定工艺路线 8

4.3.1 工艺路线一 8

4.3.2工艺路线二 9

4.3.3 最终工艺路线三 10

5 选择定位基准 11

5.1 粗基准选择 11

5.2 精基准选择 11

6.确定机械加工余量,工序尺寸 12

6.1 各工序加工余量 12

6.2 确定各工序加工余量和基本工时 13

7.夹具设计 26

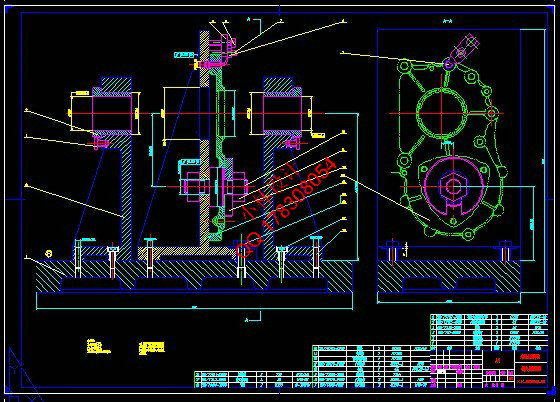

7.1 镗夹具设计 26

7.1.1镗夹具的选择与设计 27

7. 1.2夹紧机构定位方案的选择 28

7.1.3夹紧机构方案的选择 29

7.1.4夹具体的设计 30

7.1.5对刀装置 30

7.1.6夹具操作简介 30

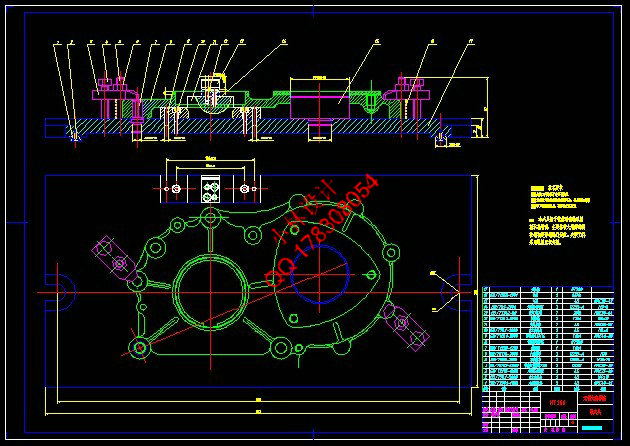

7.2 铣夹具设计 30

7.2.1铣夹具体的选择与设计 30

7. 2.2夹紧机构定位方案的选择 31

7. 2.2夹紧机构夹紧结构的分析 31

7.2.3铣夹具定位基准的选择以及误差的计算 32

8 结论与展望 33

8.1结论 33

8.2不足之处及未来展望 33

致 谢 34

参考文献 35

附录 36

|