|

|

|

|

设计名称 |

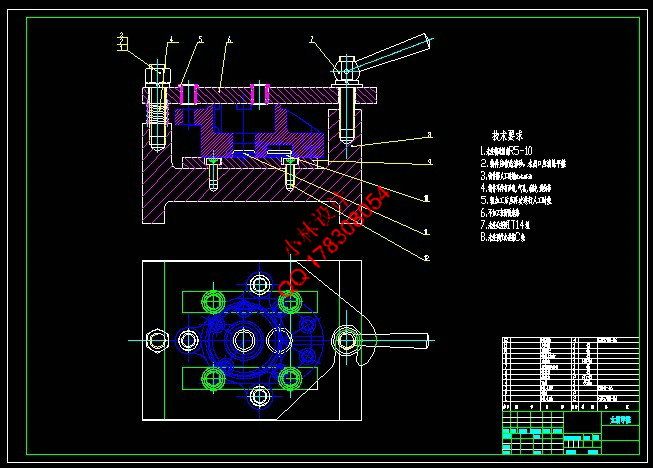

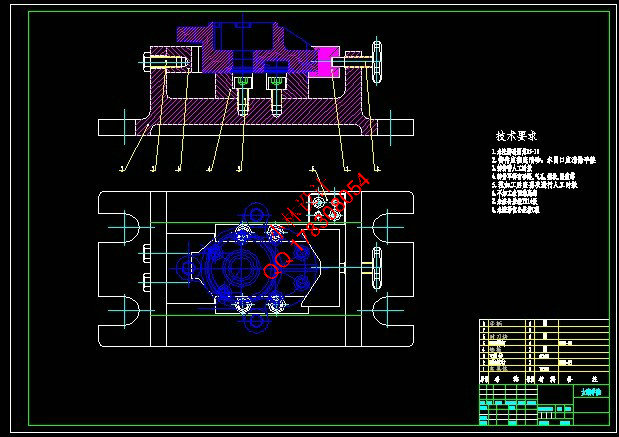

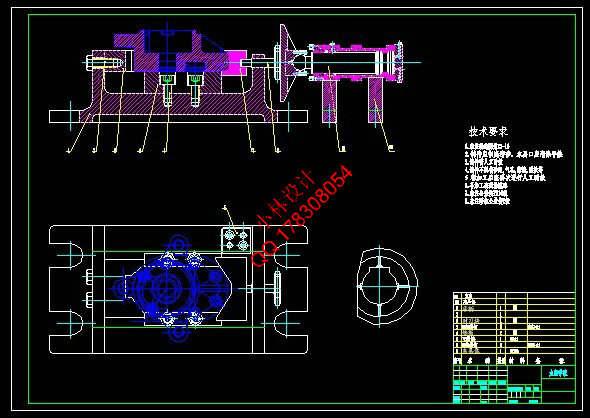

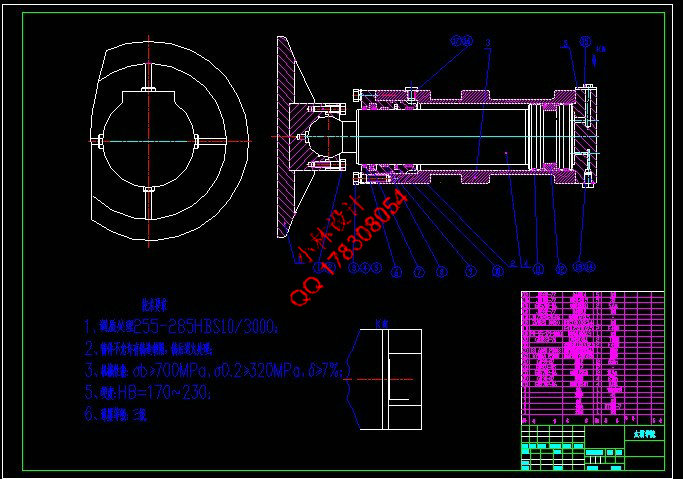

液压泵盖工艺工装设计-液压夹具[铣泵盖上平面+钻3-φ11孔] |

|

|

设计编号 |

V166 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

13000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括: CAD版本图纸,共12张

作用叶片泵,它的作用是不能被其他成分所取代,所以和泵的选择是密切相关的泵盖作为一个设计的主题,来 获取过程有关的大量书籍的过程中,最好的设计方案的综合比较与选择。液压泵盖是液压泵重要的零件之一, 采用钻、扩、铣等传统工艺,不仅效率低,而且稳定性差,精度不易保证,制约了生产的发展。应用组合机床加工 大批量零件,快捷高效,生产率高,是机械加工的发展方向。本设计主要包括液压泵盖的加工工艺过程的设计 ,应采取哪些措施存在的主要问题和液压泵盖的加工设计过程。具体确定毛坯制造形式获得,基面的选择,确 定工艺路线,加工余量的确定,工序尺寸及空白,切削用量的确定。此外,这次还给液压泵盖进行了专用夹具 设计,以及夹具操作的简要说明。在完成此次设计任务中得到老师及同学们的大力帮助,在此向他们表示衷心 的感谢。 关键词:液压泵盖;工艺;夹具设计

Abstract variable frequency pump, hydraulic pump, submersible pump, diaphragm pump, power steering pump, double action vane pump, etc.Its role cannot be replaced by other parts, and therefore I choose the pump cover closely related to the pump as the design theme. In the design process of I refer to related process books material, comprehensive comparison finally chooses the best design. Hydraulic pump cover is one of the important parts in hydraulic pump. Using the drilling, expanding, milling and other traditional techniques, is not only low efficiency, and poor stability. It’s difficult to ensure the accuracy and restrict the production development. Using a combination of machine parts in large quantities is the development direction of machining, because it’s efficient and high productivity. This design includes the design of the hydraulic pump cover process planning; the main problems of the Hydraulic pump cover processing and the measures to be taken in the Process Design. There is a specific determining blank obtained manufacturing form, the selection of base, process route determination, machining allowance, process dimension and the rough determination cutting specifications and so on. In addition, I design the special fixture for hydraulic pump cover, and made a brief description of the fixture operation. Thanks for the great help given by students to teachers in the design. Key words: Hydraulic Pump Cover; Process; Fixture Design 目录

摘 要 III |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1