|

设计描述:

文档包括:

WORD版设计说明书1份,9页,2800字

CAD版本图纸,共4张

工序卡一套

过程卡一套

一、设计题目

题目:

二、原始资料

(1) 被加工零件的零件图 1张

(2) 生产类型:中批或大批大量生产

三、上交材料

(1) 被加工工件的零件图 1张

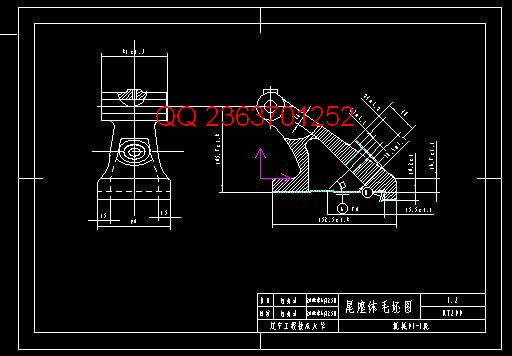

(2) 毛坯图 1张

(3) 机械加工工艺过程综合卡片(参附表1) 1张

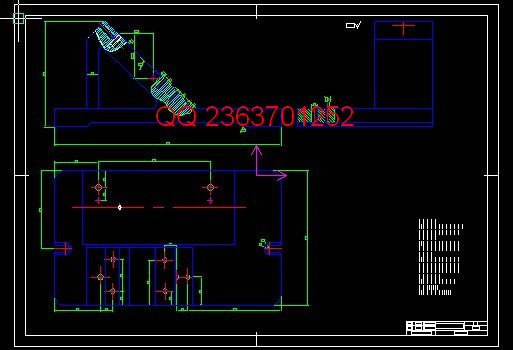

(4) 与所设计夹具对应那道工序的工序卡片 1张

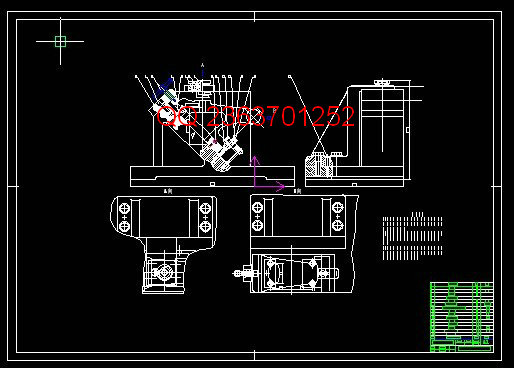

(4) 夹具装配图 1张

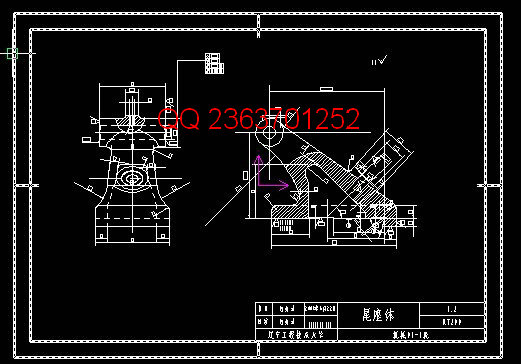

(5) 夹具体零件图 1张

(6) 课程设计说明书(5000~8000字) 1份

四、指导教师评语

摘 要

本课题主要是设计某机床尾座体的加工工艺及夹具的设计,在设计中采用先设计该尾座体的加工工艺在根据加工工艺来选取夹具的设计的方案和夹具的具体设计;而设计的重点是夹具的设计。由于工件的孔17和14都要以底面做为基准加工,故首先得做出底面的加工夹具。由于孔17的精度要求高,和定位尺寸误差小,为保证孔的位置和加工准确性我们一定在加工底面的时间通过画线找出底面的加工余量。这样就可以更好的保证孔17的位置和加工精度!加工孔14的夹具其实就是在加工底面夹具的基础上加了一个45度斜度板。

Abstract

This topic is mainly design that designs the tail a body of some tool machine to process the craft and tongses, adopting to design first in the design a body of that tail processes the craft at according to process the craft to select by examinations the tongs of the project of the design and concrete design of the tongs;But the point of design is the design of the tongs.Because the bore of the work piece 17 and 14 all want to face to be used as the basis to process with the bottom, past have to do a bottom to face first of process the tongs.Because bore 17 of accuracy have high request, and position the size error margin small, for guarantee the position of the bore and process the accuracy we certainly at process the bottom to face of time pass to draw the line to find out the bottom to face of process the amount of remaining.Thus can with better assurance bore 17 of position and process the accuracy!Process the bore 14 of tongs was in processing the foundation that the bottom faces the furniture to add one 45 degrees of gradient plank in fact.Process the bore 17 of time is opposite for assurance to run parallel with B face of in the A we have to design accurately with the AN and B faces to settle for of tongs!Return in consideration of a degree of the work piece and the error margin of the cylinder degrees are small, the furniture that we design have to the bore 17 of tongs fixed position is accurate, and process the vibration of time small, that have to in the bore 17 of neighborhood seek a fixed position to step up the point!

目 录

1零件工艺分析 1

1.1零件工艺分析 1

2机械加工工艺规程设计 1

2.1 确定毛坯的制造形成 1

2.2 基面的选择 1

2.3制定工艺路线 1

2.4 机械加工余量、工序尺寸及毛坯的确定 2

2.4.1 孔 的内径表面 2

2.5确定切削用量及基本工时 2

2.5.2.钻孔(钻 14的孔) 3

2.5.3.扩孔(扩 14的孔) 4

2.5.4.镗削(镗削 的孔) 5

3指定工序的专用夹具设计 5

3.1问题的提出 5

3.2夹具设计 5

3.2.1 孔的加工夹具 5

4方案的综合评价与总结 7

5体会与展望 7

6参 考 文 献 8

|