|

设计描述:

文档包括:

WORD版设计说明书1份,共33页,约17000字

CAD版本图纸,共5张

摘 要

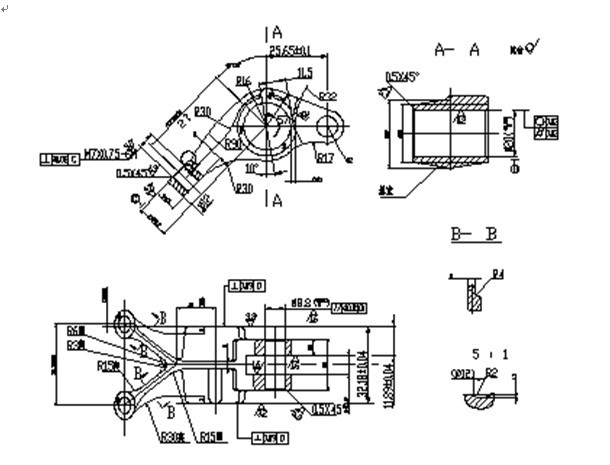

此次设计是对465发动机排气摇臂的加工工艺和夹具设计,其零件为铸件,具有体积小,零件复杂的特点,由于面比孔易加工,在制定工艺规程时,就先加工面,再以面为基准来加工其它,其中各工序夹具都采用专用夹具,特别的对于加工大头孔、槽和钻小头孔斜面小孔的工序中,选一面两销的定位方式,并以操作简单的手动夹紧方式夹紧,其机构设计简单,方便且能满足要求。

零件是465发动机排气摇臂,它位于配气机构中,与凸轮轴配合实现气门的正常开启和关闭,是发动机正常运转。制定工艺路线的出发点是使零件的几何形状、尺寸精度及位置精度等技术要求能得到合理的保证。考虑采用万能性机床配以专用夹具,并尽量使工序集中来提高生产率。夹具是一种能够使工件按一定的技术要求准确定位和牢固夹紧的工艺装备,广泛地运用于机械加工,检测和装配等整个工艺过程中。

关键词:465发动机;摇臂;加工工艺;专用夹具;夹具设计

Abstract

This design is to 465 engine exhaust rocker arm the components the processing craft and the jig design, its components are the forging, has the volume to be small, components complex characteristic,Because the surface is easier than the hole to process, when formulation technological process, first the machined surface, then processes other take the surface as the datum,In which various working procedures jig all uses the unit clamp, special regarding processes the big end of hole, the trough and drills the capitellum hole incline eyelet in the working procedure, Chooses locate mode which two sells at the same time, and operates the simple manual clamp way clamp, its organization design is simple, the convenience also can satisfy the request.

465 engine parts exhaust rocker arms, which is located in the valve train, camshaft with the realization of valve opening and closing, is the normal engine operation. Development of process routes starting point is to make the geometric shape, size, location precision,accuracy and technical requirements can be reasonable assurance. Consider the universal nature of machine accompanied by special fixtures, and try to focus on processes to improve productivity. Workpiece fixture is a way to make certain technical requirements in accordance with accurate positioning and firm clamping of the technical equipment, widely used in machining, inspection and assembly process of the whole process.

Key words: 465engine; rocker Arm; the processing craft; unit clamp; design of fixture

目 录

第1章 概述 1

1.1 课题研究现状及选题目的和意义 1

1.2 文献综述课题研究现状及分析 1

1.3 基本内容及拟解决的主要问题 3

第2章 零件的分析 5

2.1 零件的作用 5

2.2 零件的工艺分析 5

2.3 零件毛坯种类的选择 7

2.4 本章小结 7

第3章 排气摇臂机械加工工艺规程设计 8

3.1 制定工艺路线的作用 8

3.2 制定工艺路线 9

3.3 机械加工余量、毛坯尺寸的确定 11

3.4 确定切削用量及切削工时 13

3.5 本章小结 18

第4章 夹具的设计 19

4.1 机床夹具的现状及发展 19

4.2 机床夹具的功用及夹具的成组和分类 20

4.3 机床夹具的设计特点 22

4.4 机床夹具的设计要求 23

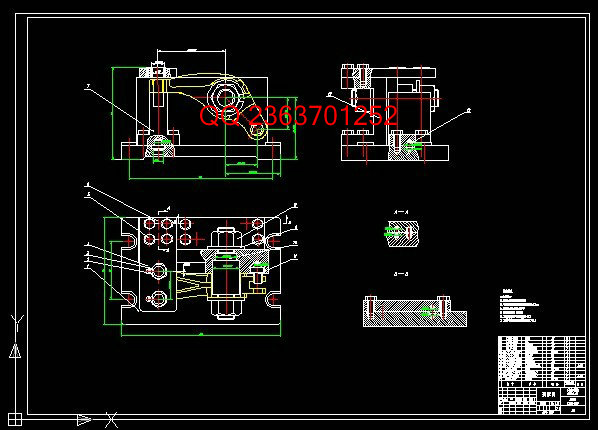

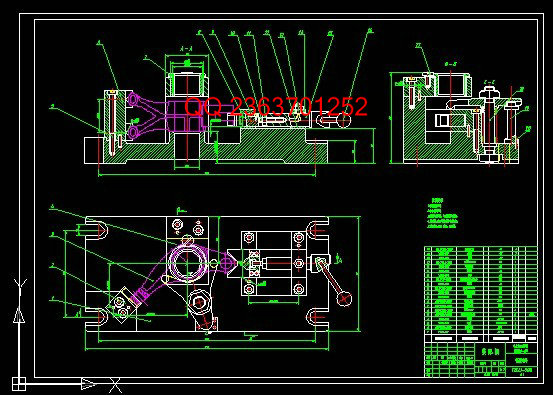

4.5 Φ20孔加工钻床夹具装配图设计 24

4.6 压板螺栓强度校核 26

4.7 定位误差的分析 28

4.8 本章小结 28

结 论 29

参考文献 30

致 谢 31

|