|

设计简介 |

设计描述:

文档包括:

Word版设计说明书1份,共18页,约6800字

CAD版本图纸,共4张

工序卡一套

过程卡一套

摘要

现今的世界国家间的竞争已经全面转入科学技术的竞争,而机械工业直接反应一个国家的整体技术水平。无论是核工业还是农具,机械制造业是国家获取其他几乎一切行业设施和工具的来源。可以说人类文明史就是机械制造的历史。

我国的工业化建设情况,国际上众说纷纭,虽然在很多高技术项目上颇有建树,但在这次汶川地震中表现出中众多缺陷。包括规模较小,工艺粗糙,关键技术仍依赖国外等等。充分说明在向高技术领域进军的同时,低端产业也应该加强建设。

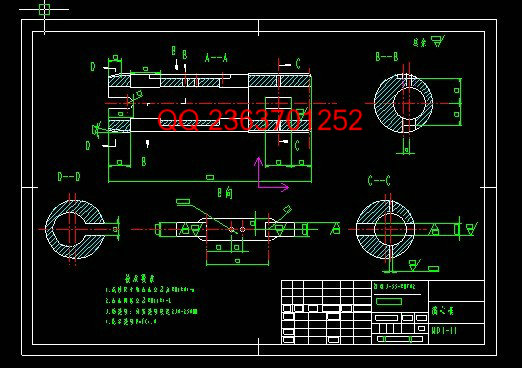

本说明书是为加工机械零件偏心套的加工过程而编写。偏心套以其偏心结构实现内孔直径可调,加上紧定螺丝,以达到内圈周向、轴向固定的目的。但因为内圈内孔是间隙配合,一般只用于轻载、无冲击的场合。是一种较为常见的机械零件。

关键词:偏心套 零件 加工过程

ABSTRACT

Nowadays,the competition of world countries has shift to the competition of new science and technology completely,In this age , level of development for the machine industry has become the most important criteria in the judgement in a country’s level of development.From Nuclear industry to dead stock,ALL the establishment and facilities,hat our country need and consume, depend on our machine industry .The histroy of mankind is the histroy of the machine building

Consider chinese industry construction,Many argumentations has been bring forward in the globality organization.We enjoy our achievement in some new technologes.But in these serious earthquake in WENCHUAN,we discovered our weakness: dimensions, asperous technics,core technology depend on other countries.So notwithstanding these is the age of advanced krowlage,we must improve our well-rounded technologies.

These instruction book is for machine hardware eccentric bushing’s processing cycle . The eccentric bushing with their proprietary composition accommodate inside diameter ,use the screw to realize the accommodate of inner ring’s lock-up.Byt bacause their clearance fit composition, they apply to non- or light- load.They are a type of frequently-used machine hardware.

Key word : eccentric bushing , machine hardware, processing cycle

目录

1 零件工艺性分析----------------------------------------------------------5

1.1 用途-----------------------------------------------------------------------5

1.2 技术要求-----------------------------------------------------------------5

1.3 工艺性--------------------------------------------------------------------6

1.4 生产类型-----------------------------------------------------------------6

2 机械加工工艺规程设计-------------------------------------------------6

2.1 确定毛坯,绘制毛坯简图--------------------------------------------6

2.2 定位基准-----------------------------------------------------------------7

2.3 加工方法-----------------------------------------------------------------7

2.4 加工阶段与工序--------------------------------------------------------8

2.5 10 2,2 R5侧槽与侧孔的加工余量,尺寸公差----------------8

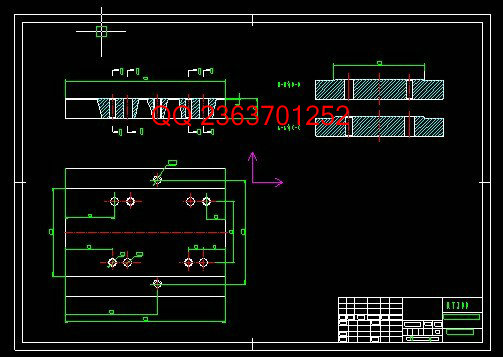

3铣削加工夹具设计-------------------------------------------------------10

3.1夹具定位装置与定位方案--------------------------------------------10

3.2夹紧装置----------------------------------------------------------------12

3.3 对刀装置---------------------------------------------------------------13

3.4 夹具与机床连接元件------------------------------------------------13

3.5 夹具体------------------------------------------------------------------14

4方案综合评价与结论----------------------------------------------------14

5体会与展望----------------------------------------------------------------15

6参考文献-------------------------------------------------------------------17

|