|

|

|

|

设计名称 |

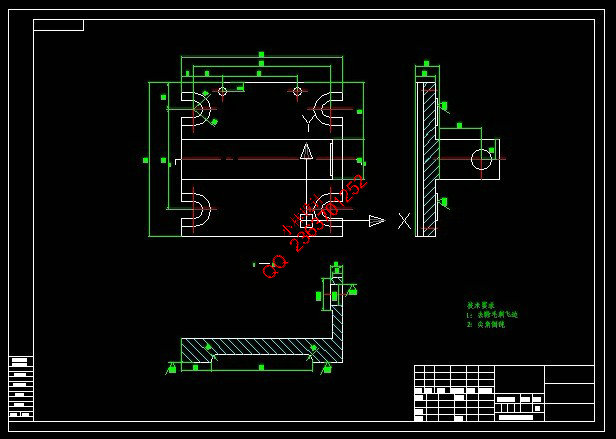

摇臂支架的加工工艺及钻Φ2mm孔夹具设计 |

|

|

设计编号 |

V553 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

5800字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

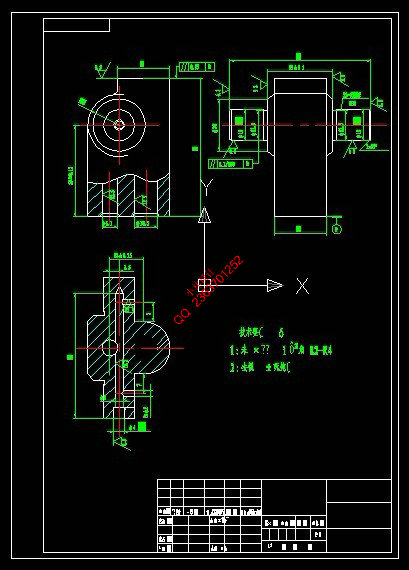

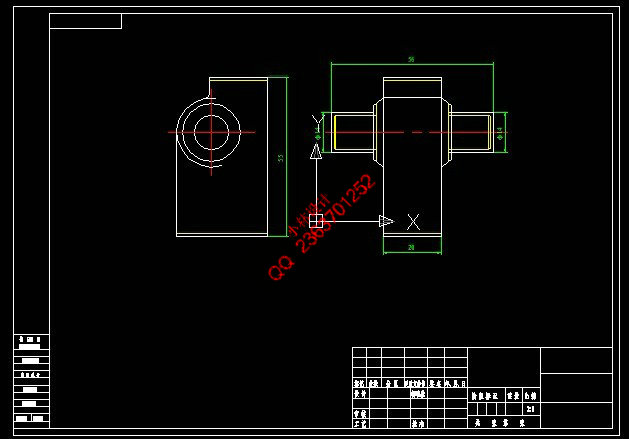

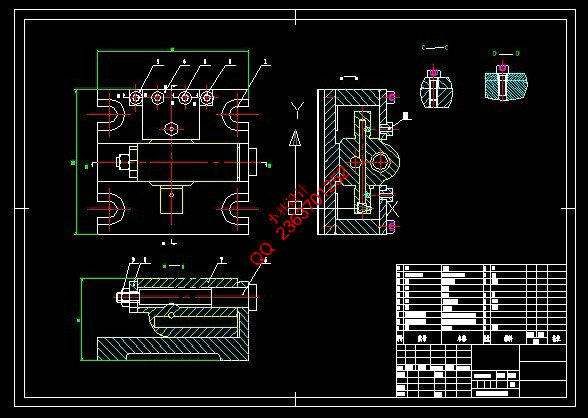

文档包括: CAD版本图纸,共4张

摘 要 工序卡片各一张。根据零件的性质和零件图上各端面的粗糙度确定毛坯的尺寸和机械加工余量。最后拟定

工艺路线图,制定该工件的夹紧方案,画出夹具装配图。 我们在进行毕业设计之前对所学各课程的一次深入的综合性的总复习,也是一次理论联系实际的训练,因此,

它在我们四年的大学生活中占有重要的地位。 分析问题、解决问题的能力。由于能力所限,设计尚有许多不足之处,恳请各位老师给予指导。

Abstract one of the assembly, machining process card and the card with a process. According to the nature of parts and components in the face of the map on the roughness of rough determine the size and mechanical Jiagongyuliang. Finalizing the road map process, the enactment of the

workpiece clamping programme, to draw fixture assembly. course of the University, technology and the most basic course after the specialized, which is our graduation project before conducting the various courses of study by an in-depth comprehensive review of the total, is also a Theory with practical training, therefore, in

our four years of university life occupy an important position. in the work of a real training exercise from its own analysis, problem-solving abilities. As capacity constraints, there are still many deficiencies in the design, ask teachers to give

guidance. |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1