|

|

|

|

设计名称 |

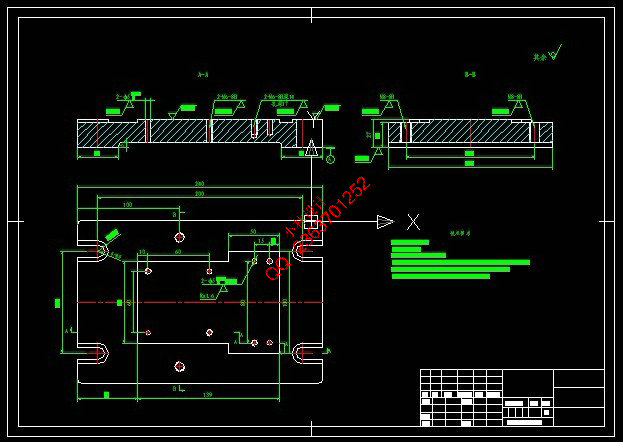

泵体加工工艺及镗Ф30孔的夹具设计 |

|

|

设计编号 |

V565 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

5900字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

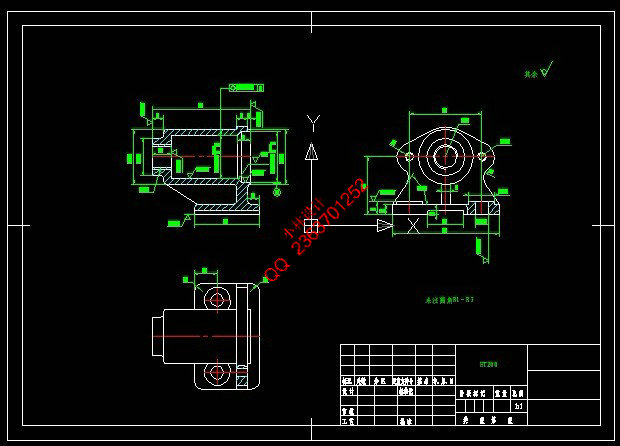

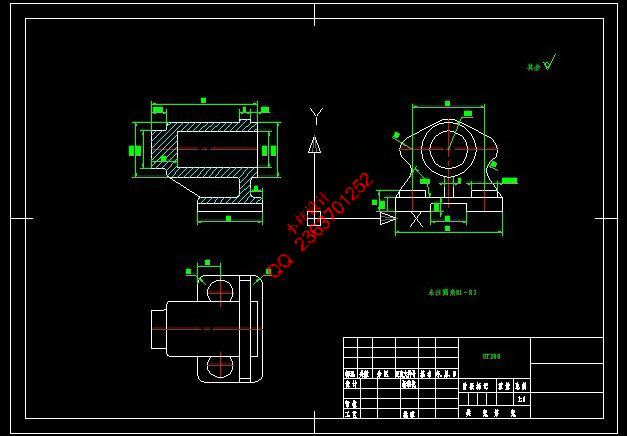

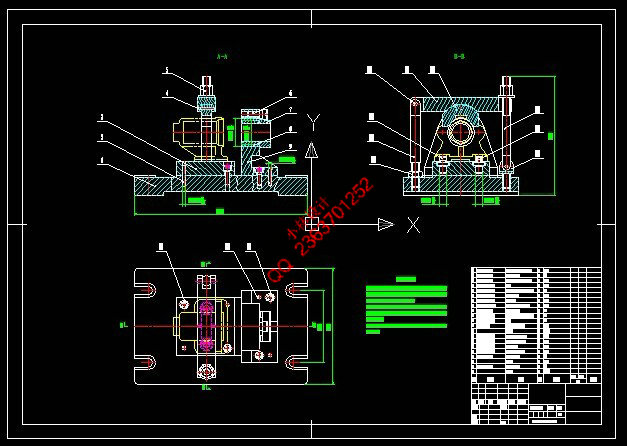

文档包括: CAD版本图纸,共4张 摘 要

本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。 分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基 准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装 备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引 导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合 理性与不足之处,并在以后设计中注意改进。 关键词:工艺、工序、切削用量、夹紧、定位、误差。 ABSTRCT This design involves the machinery manufacturing process and fixture design, metal cutting

machine tool, tolerance and measurement and other aspects of knowledge. machining process design, process design and fixture three. In process design should first of all parts for analysis, to understand part of the process to design blank structure, and choose the good parts machining datum, design the process routes of the parts; then the parts of each step in the process to the size calculation, the key is to determine the craft equipment and the cutting dosage of each working procedure design; then the special fixture, the fixture for the various components of the design, such as the connecting part positioning devices, clamping element, a guide element, fixture and machine tools and other components; positioning error calculated by the analysis of fixture, jig structure the rationality and

the deficiency, pay attention to improving and will design in. localization, the error 目 录 序言…………………………………………………………………1

一. 零件分析 ……………………………………………………2 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!