|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共25页,约11000字

CAD版本图纸,共17张

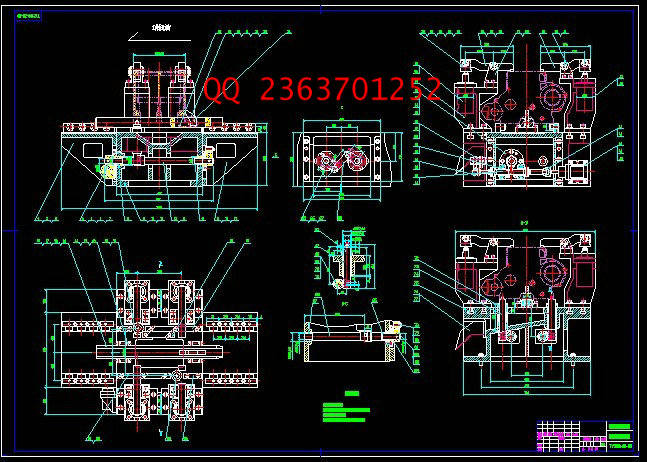

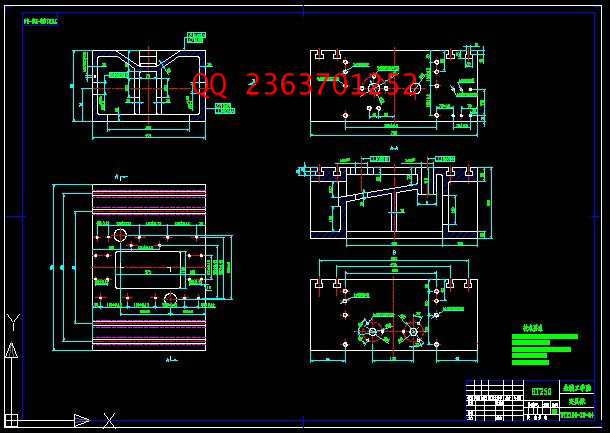

TY2100柴油机机体缸孔粗镗组合机床及夹具计

摘要 :组合机床是以系列化、标准化的通用部件为基础,配以少量的专用部件组成的专用机床。

组合机床兼有低成本和高效率的优点,在大批、大量生产中得到广泛应用,并可用以组成自动生产线。组合机床装备的发展思路是以提高组合机床加工精度、组合机床柔性、组合机床工作可靠性和组合机床技术的成套性为主攻方向更关键的是现代通信技术在机床装备中的应用,信息通信技术的引进使得现代机床的自动化程度进一步提高,操作者可以通过网络对机床的程序进行远程修改,对运转状况进行监控并积累有关数据;通过网络对远程的设备进行维修和检查、提供售后服务等。

本次设计的是一台加工TY2100柴油机机体缸孔的粗镗组合机床,具体进行总体设计和夹具设计。课题来源于盐城市江动集团。先制定工艺方案,确定机床配置型式及结构方案。然后进行三图一卡设计,其中包括被加工零件工序图、加工示意图、机床联系尺寸图、生产率计算卡、有关设计计算、校核。最后是夹具设计,其中包括夹具总装图、夹具体零件图、其它零件图、有关计算、校核等。

关键词 组合机床;粗镗;配置;夹具

TY2100-cylinder engine block rough boring machine tool and fixture combinations of

Abstract: The combination of machine tools is serialized, standardized components based on the common, supported by a small number of dedicated components for the machine.

Machine combination of both low-cost and high efficiency advantages of a large number of the large number of widely used in the production, and for the composition of automated production lines. The combination of machine tools and equipment development ideas on improving precision machining portfolio, flexible combination of machine tools, machine tools combination of reliability, and the combination of machine tool technology packages for the main direction of the more critical that modern communications technology in machine tools and equipment in the application of information and communication technology Makes the introduction of modern machine tools to further enhance the degree of automation, network operators can be passed on the machine remotely modify the procedures for monitoring the status and operation of the accumulated data through the network of remote equipment maintenance and inspection, to provide after-sales service, and so on.

The design is a processing TY2100-cylinder engine block the combination of rough boring machine, a specific design and fixture design. Jiang's move from Yancheng subject Group. To the development of the programme, established pattern and structure of machine-targeted programmes. Followed by three one card design plans, including the processing parts process map, diagram processing, machine tools Contact size map, productivity calculation cards, the design, check. Finally, there is fixture design, including the fixture hand, folder specific parts map, other parts map, relevant terms, such as checking.

Key words: combination machine; rough boring; allocation Fixture

目 录

1 前言 1

2 组合机床总体设计 3

2.1 总体方案论证 3

2.1.1 加工对象工艺性分析 3

2.1.2 机床配置型式的选择 3

2.1.3 定位基准的选择 3

2.2 确定切削用量 4

2.2.1 选择切削用量 4

2.2.2 计算切削力、切削扭矩及切削功率 5

2.3 三图一卡设计 8

2.3.1 被加工零件工序图 10

2.3.2 加工示意图 9

2.3.3 机床联系尺寸图 10

2.3.4 机床生产率计算卡 11

3 组合机床夹具设计 13

3.1.1 零件的工艺性分析 13

3.1.2 夹具设计的基本要求 13

3.2 定位方案的确定 13

3.2.1 定位方案的论证 14

3.2.2 定位基准的选择 15

3.2.3 定位的实现方法 15

3.3 误差分析 15

3.3.1影响加工精度的因素 15

3.3.2保证加工精度的条件 16

3.4 夹紧方案确定 17

3.4.1 夹紧装置的确定 17

3.4.2 夹紧力的确定 18

3.4.3 夹紧液压缸的选择 19

3.5 导向装置的选择 20

3.5.1 镗模型式的选择和设计 20

3.6 夹具体确定 20

4 结论 22

参考文献 23

致 谢 24

附 录 25

|