|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共32页,约15000字

CAD版本图纸,共8张

摘 要

随着数控技术的发展和普及,加工中心的作用越发突显它的重要性。为进一

步提高数控机床的加工效率,数控机床正向着工件在一台机床一次装夹即可完成

多道工序或全部工序加工的方向发展,因此出现了各种类型的加工中心机床,如

车削中心、镗铣加工中心、钻削中心等等。这类多工序加工的数控机床在加工过

程中要使用多种刀具,因此必须有自动换刀装置,也就是所说的刀库,以便选用

不同刀具,完成不同工序的加工工艺。自动换刀装置应当具备换刀时间短、刀具

重复定位精度高、足够的刀具储备量、占地面积小、安全可靠等特性。

本论文是开发设计出一种体积小、结构紧凑、价格较低、生产周期短的小型

立式加工中心刀库本文。首先介绍了国内外加工中心研究现状及发展趋势,阐明

了本课题研究的目的、意义。然后进一步介绍本小型加工中心刀库总体结构和各

部件方案的选择,并在此基础上进行了小型加工中心刀库的机械结构的设计计算,

主要包括刀盘部件设计(含刀盘,夹块,刀爪),刀库转动定位机构设计(含转臂,

槽轮,滚子,锁止盘),刀库总体机构设计(含轴承套,轴,箱盖,箱体)刀库移

动部分设计。

关键词:数控系统 加工中心 刀库 机械手

ABSTRACT

Along with the numerical control technology development and the

popularization, the processing center function reveals its importance even more

suddenly.For further enhances the numerical control engine laths the processing

efficiency, the numerical control engine laths is clamping to the work piece in an

engine laths attire then completes the multi-channel working procedure or the complete

working procedure processing direction develops, therefore appeared each kind of type

processing center engine laths, like the turning center, the boring mill processing center,

drills truncates center and so on.This kind of working procedure processing numerical

control engine laths must use many kinds of cutting tools in the processing process,

therefore must have trades the knife installment automatically, also is the knife

storehouse which said, in order to select the different cutting tool, completes the

different working procedure the processing craft.Trades the knife equipment to have

automatically to have trades the knife time short, the cutting tool repetition pointing

accuracy high, the enough cutting tool margin, the area small, safe reliable and so on

the characteristics.

The present paper is the development designs one kind of volume slightly, the

structure compact, the price is low, production cycle short small vertical processing

center knife storehouse this article.First introduced the domestic and foreign

processing center research present situation and the trend of development, have

expounded this topic research goal, the significance.Then further introduced this small

processing center knife storehouse overall structure and various parts plan choice, and

has carried on the small processing center knife storehouse mechanism design

calculation in this foundation, mainly includes the knife storehouse overall

organization design, the electrical machinery selection, the knife storehouse rotation

detent mechanism design knife storehouse migration part design and so on.

Keywords: numerically controlled lathe; machining centers ; cut database ;

mechanical hand

1、绪言……………………………………………………………4

2、毕业设计工艺要求的基本任务和要求……………………………………4

2.1、基本任务………………………………………………………………………5

2.1.1、工艺设计的基本任务……………………………………………………6

2.1.2、夹具设计的基本任务……………………………………………………6

2.2、设计要求……………………………………………………6

2.2.1、工艺设计的设计要求……………………………………………………6

2.2.2、夹具设计的设计要求……………………………………………………6

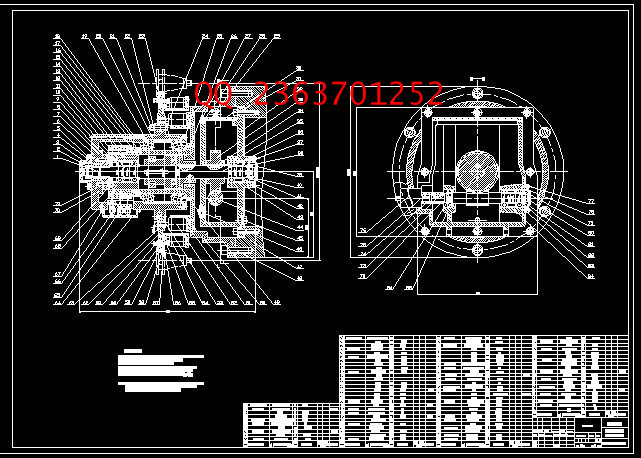

3.1 刀库的结构设计……………………………………………………………8

3.1.1 刀库主要参数的确定………………………………………………… 10

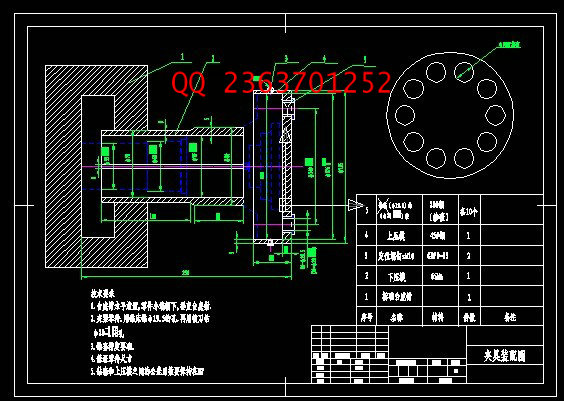

3.1.2 刀盘部分的设计……………………………………………………… 10

3.1.3 刀库转动定位机构的设计……………………………………………10

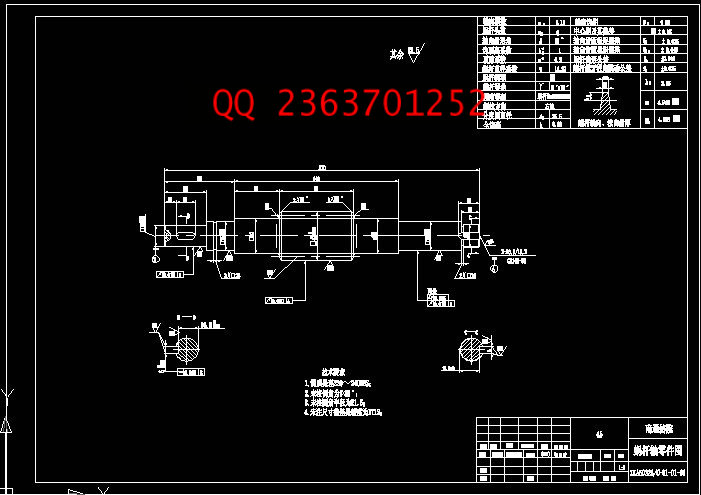

3.1.4 轴的设计…………………………………………………………………11

3.1.5 滚动轴承的选择计算…………………………………………………12

3.1.6 键的选用与计算……………………………………………………… 13

3.1.4 刀库的支承部分的设计…………………………………………… 14

3.2 刀库移动部分的设计…………………………………………………… 14

3.2.1 刀库支承横梁和导轨的设计……………………………………… 14

3.2.2 刀库移动丝杠和电机的选择…………………………………… 15

3.3 刀库、横梁的安装…………………………………………………… 16

4 刀具交换装置的设计…………………………………………………… 16

4.1确定换刀机械手形式………………………………………………………18

4.2换刀机械手的工作原理……………………………………………………22

4.3机械手的自动换刀过程的动作顺序………………………………………22

4.4机械手回转轴4上的齿轮齿条设计………………………………………23

4.5自动换刀装置的相关技术要求……………………………………………24

4.5.1主轴准停装置…………………………………………………………24

4.5.2换刀机械手的安装与调试……………………………………………24

4.6自动换刀程序的编制…………………………………………………… 26

5 自动换刀装置的控制原理………………………………………………… 27

5.1自动换刀装置的液压系统原理图……………………………………… 28

5.2自动换刀装置换刀动作的顺序控制过程……………………………… 29

6、经济型数控机床改造时数控系统的选用……………………… 31

小结………………………………………………………………………………31

参考文献…………………………………………………………………………32

|