|

|

|

|

设计名称 |

CA6140车床手柄座加工工艺及钻φ10mm孔夹具设计[B型] |

|

|

设计编号 |

U1732 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

12000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

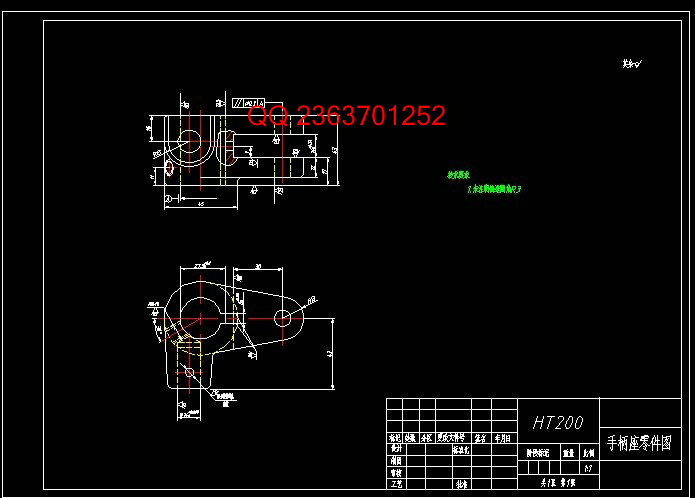

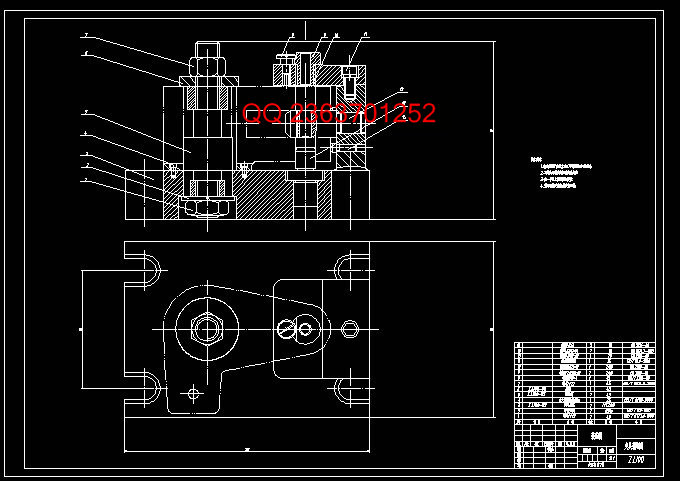

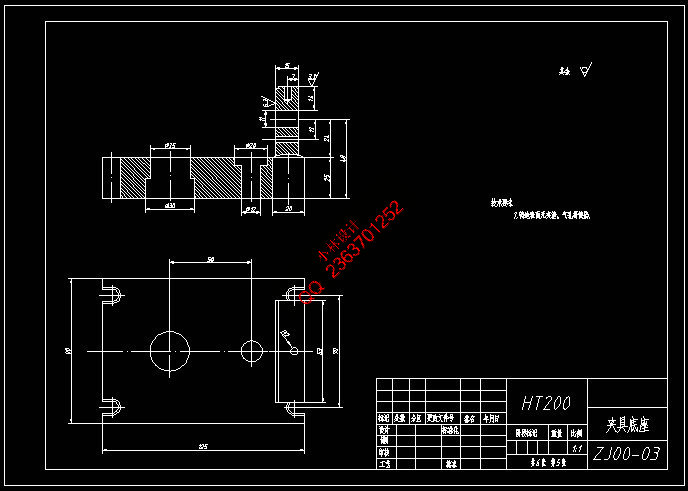

手柄座零件机械加工工艺和典型夹具设计 手柄座零件是车床操纵部分的组成零件之一,该手柄座的作用相当于一个连杆,车床外部手柄的运动是通 过车床手柄座传递到车床内部实现人为对机床的操纵。在设计中,主要目的是根据零件选择合理的工艺路 线,然后制定出一套可行的夹具。本文涉及两大部分,第一部分是对手柄座零件的分析及工艺规程的制定 ;第二部分是对于零件中的两次钻孔加工采用不同的定位、夹紧方式进行典型夹具的设计。通过设计一方 面使我们更进一步熟悉了产品加工设计的全过程,在制定加工方案的时候,充分考虑其经济性和可行性。 另一方面通过对手柄座零件的机械加工工艺规程设计和钻孔用夹具设计,试图找出一种简单、实用的加工 方法,以供生产同类零件的企业参考。 关键字:手柄座;工艺;夹具

ACTS as a connecting rod. Movement is handle by lathe external handles to the lathe internal implementation artificial control for machine tools. In the design, the main task is according to the parts during the design and calculation, including processing machine tools, spindle speed, the three elements of cutting the reasonable selection of the processing technology, as well as the typical fixture design. This article involves two parts, the first part is the analysis of the handle seat parts and processing procedures. Two drilling in the second part is for parts with different way of positioning, clamping typical fixture design. Through the design on the one hand, make us more familiar with the whole process of the product processing design, at the time of processing plan formulation, give full consideration to its economical efficiency and feasibility. On the other hand through the handle parts of the machining process planning design and drilling fixture design, trying to find out a simple and practical processing methods, to provide the reference for the manufacture of similar parts. Key words: the handle seat; process; fixture

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1