|

设计简介 |

文档包括:

设计word版本说明书一份,共17页,约7200字

开题报告一份

外文翻译一份

CAD版本图纸,共3张

目 录

1前言 4

1.1国内外夹具行业及机床夹具的现状 4

1.1.1国内夹具行业的现状 4

1.1.2 国外夹具行业的现状 4

1.1.3 机床夹具现状 4

1.2设计的目的 4

1.3设计的意义 5

1.4任务来源 5

1.5设计原则 5

1.6设计主要资料 5

1.7设计工艺规程 5

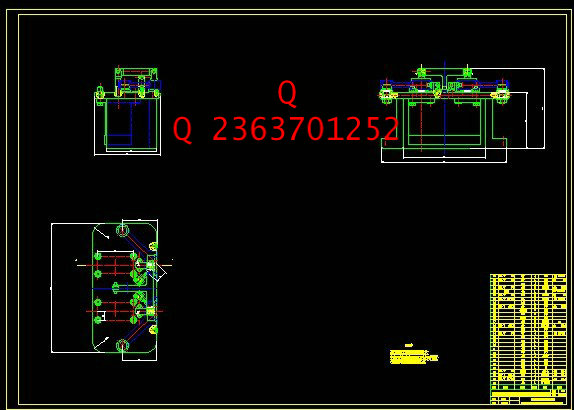

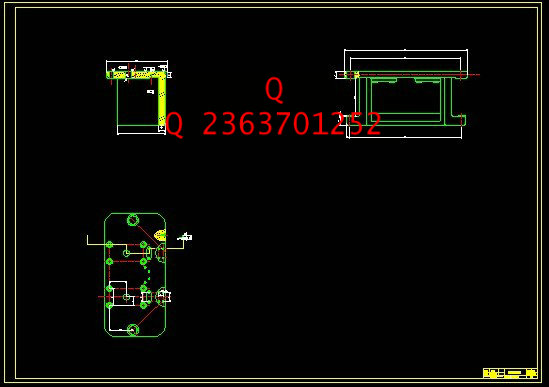

2连杆体拉结合面夹具设计 6

2.1连杆的加工工艺 6

2.2生产纲领的计算 7

2.3连杆体拉结合面夹具定位方式的选择 7

2.4拉削加工方案的选定 7

2.5切削力的计算及拉削方式的确定 9

2.5.1半精拉切削力的计算 9

2.5.2精拉切削力的计算 11

2.6拉削加工时间的计算 12

2.7气缸的选取 12

2.8夹紧机构间传动小轴的选择及校核计算 13

3.总结 14

4.参考文献 15

5.致 谢 16

摘 要

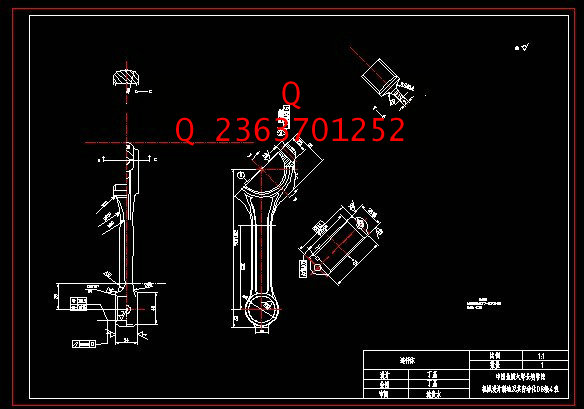

连杆是柴油机运动的主要关键件之一,它工作的稳定性、可靠性对柴油机的整机质量至关重要,质量轻、精度高的连杆,有助于降低柴油机的能耗和噪声。该设计说明书首先介绍了国内外夹具及机床夹具的现状、夹具设计的目的、意义、原则和一些设计所需要的主要的资料,主要说明了连杆拉结合面夹具设计过程,其中包括连杆的加工工艺、生产纲领的计算、连杆体拉结合面夹具定位方式的选择、拉削加工方案的选定、切削力的计算及拉削方式的确定、拉削加工时间的计算、气缸的选取、夹紧机构间传动小轴的选择及校核计算,最后简洁的总结设计所取得的结果及此次设计的优点,譬如采用了气动夹紧装置,对以后夹具的发展方向给予一些建议。

关键词 连杆体精拉结合面;夹具设计;工艺分析

ABSTRACT

Diesel engine connecting rod is the key piece of sports, it works the stability, reliability is critical to the quality of the diesel engine machine, light weight, high precision, connecting rod, help reduce energy consumption and engine noise. The design specification introduces the domestic and international fixtures and the status of jigs and fixtures, fixture design purpose, meaning, some design principles and key data needed, mainly to explain the combination of surface tension rod fixture design process, including the connecting rod Processing technology, the calculation of the production program, connecting rod body pull mode with the choice of surface fixture, broaching processing program selected, the calculation of cutting force and determine the way broaching, broaching the calculation of processing time, the cylinder selected folder Tight inter-agency drive the choice of a small shaft and checking calculations, the final design brief summary of the results achieved and the advantages of this design, such as using a pneumatic clamping device, fixture on the future direction of development to give some suggestions.

Key words: connecting rod body with fine surface tension; fixture design; Process Analysis

|