|

|

|

|

设计名称 |

CA6140车床拨叉[831006]工艺及铣16槽夹具设计【C型】 |

|

|

设计编号 |

B029A | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

20000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

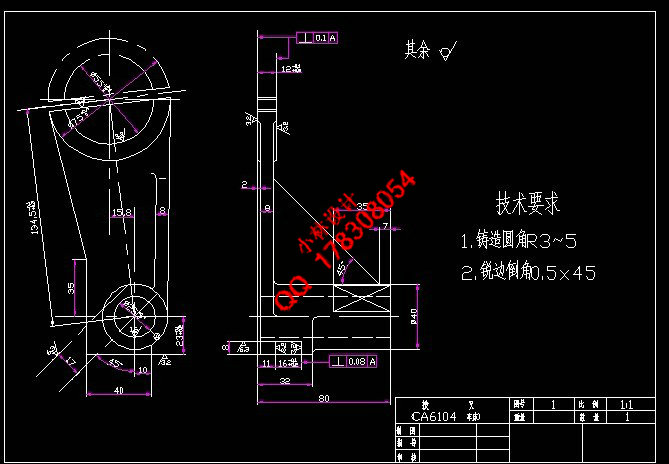

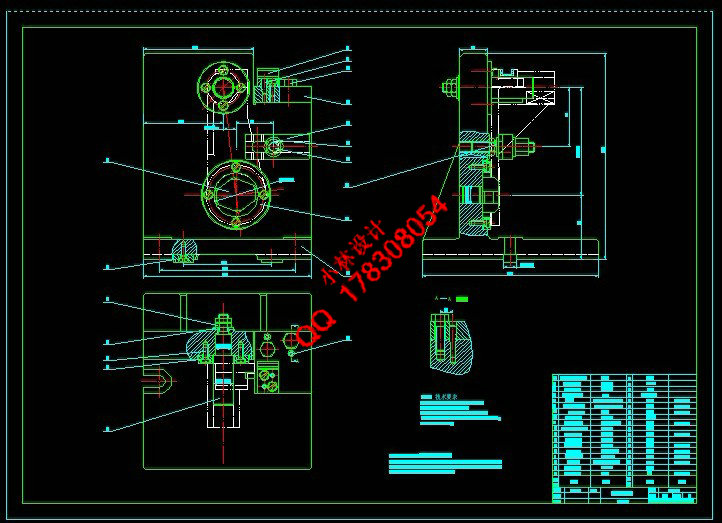

文档包括: 摘 要 本设计是车床拨叉零件的加工工艺及专用夹具设计。从零件的结构外型分析,它的外型复杂,且不易加工,因此该零件选用是铸造件。它的主要加工面是孔、拨叉叉口两端面和槽,在加工中由于面的加工精度要比孔的加工精度容易保证。因此,在设计中采用先面后孔的原则,并将孔与平面的加工划分为粗加工和精加工阶段,以保证加工精度。在本设计中,先以一个面加工出一个基准面,然后,再以该基准面加工相应的孔。在后面的工序中,均以该孔为定位基准,加工拨叉叉口两端面、孔、底平面、槽和斜平面,在整个加工过程中,分别采用了铣床、钻床和镗床。并设计了铣侧面、镗孔和铣槽等的专用夹具,并对它们的定位都采用了一面两销定位。由于该零件的尺寸不大,所需的夹紧力不大。因此,夹紧方式都采用手动夹紧,它的夹紧简单,机构的设计更为方便,满足夹紧要求。

ABSTRACT This design is a lather plectrum parts processing and special fixture designs. Parts from the appearance of the structure, its appearance complex and difficult process, so the selection of parts is casting.The parts are cast parts. In the processing, it is easier to ensure the processing accuracy of plane than the hole. So the parts’ main planes are hole, two blades of the Plectrum and groove. Therefore, in the design, it adopts the principle of plane first and hole second and divides the hole and plane’s working into extensive and intensive processing stages so as to ensure the accuracy. In this design, firstly, it uses the plane to work a datum; secondly, it uses the datum to work according hole. And in the latter process of working, it also takes hole as the poisoning base and works the two bales of Plectrum, hole, bottom plane, groove and inclined plane. In the entire machining process, it uses separately the milling machine, driller and boring machine. And the design aspect of milling, boring and milling ducts special fixture. They also have adopted the positioning of a two marketing positioning. According to the requirement, it designs the special fixture. For the size of parts is not very big, it doesn’t require strong clamping force. Therefore, methods of clamping are manual clamping; that is because it is simple and the design is more convenient to meet the requirements of clamping.

目 录

摘 要………………………………………………………………………………………Ⅰ

1 绪论……………………………………………………………………………………………1 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1