|

|

|

|

设计名称 |

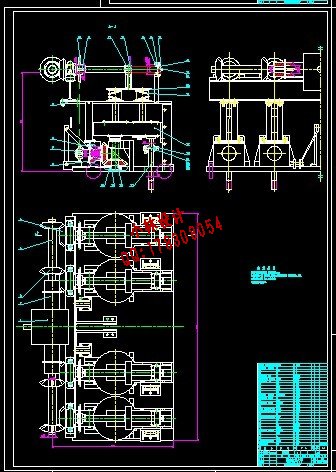

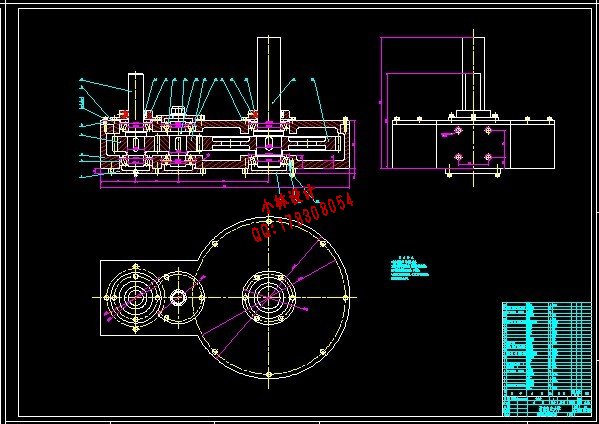

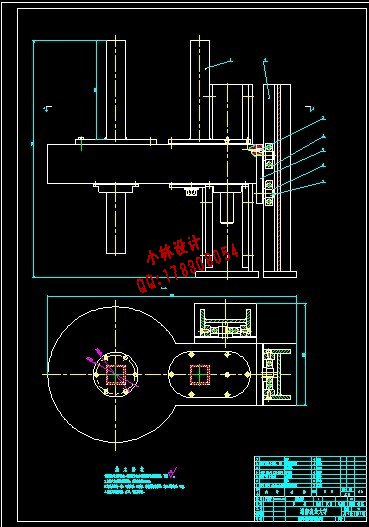

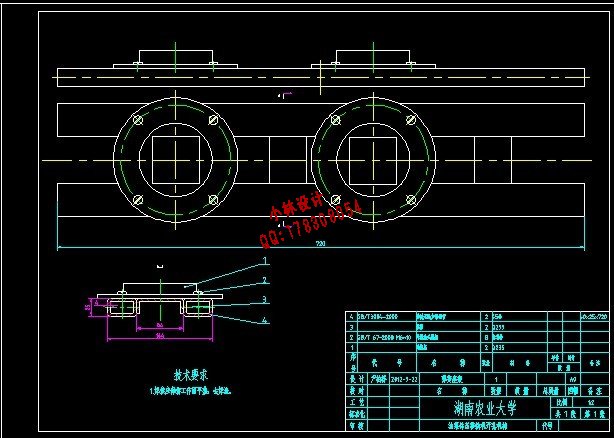

油菜钵苗移栽机开孔机构结构设计 |

|

|

设计编号 |

B040 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

17000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

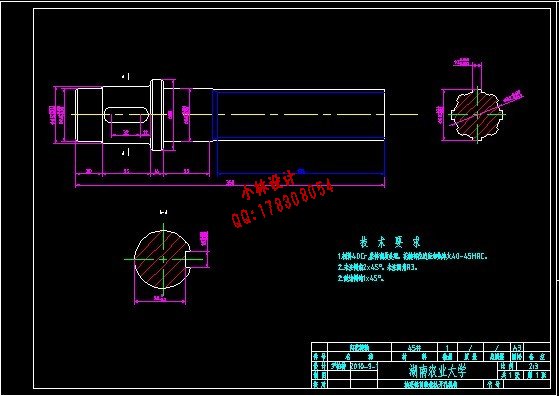

文档包括: CAD版本图纸共17张

摘 要:我国油菜大面积生产采用机械移栽是农时、农艺条件的必然选择,是社会发展的必然需求。但我国油菜移栽机械研究处于刚起步阶段,机械技术与配套农艺技术都缺乏成熟的模式。根据我国国情,油菜移栽机械应追求中小型、多功能复式作业,通过机具作业体现高效率.移栽机具能适应裸苗也能适应带土钵苗,提高机具对秧苗形式和作物种类的适应性。为降低机具造价,多行自动化应是今后油菜移栽机械的主要机型。本文主要对油菜钵苗移栽机开孔机构的动力选型,传动方案的设计,以达到所需要求。

The Design of Rape Seedlings Transplant Machine Hole Institutions Structure

Abstract : Large area of rape planting by machine is not only the farming, agronomic developing inevitable choice, but also the result of social development requirement. But the rape transplanting machine study in our country just at the beginning , mechanical technology and supporting agricultural technology are lack of mature mode. According to national conditions, rape transplanting machine product should pursue small and medium, multi-function as a goal,through machine work show high efficiency compare with handwork. Besides,transplanting machine should adapt to the soilless seedlings but also the taking-soil seedlings. In order to reduce the cost of the machine. The first choice of the rape transplanting machine scheme should be automatic line. In order to meet the requirements, in this paper, the main is put on the design of rack and the transmission project.

目 录

摘要……………………………………………………………………………………1 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1