|

设计描述:

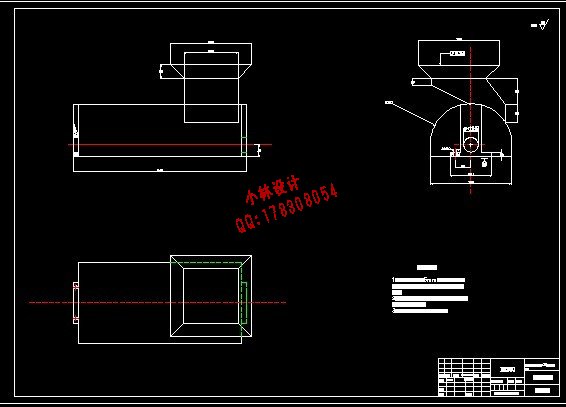

文档包括:

说明书一份,21页,月13000字

CAD版本图纸共14张

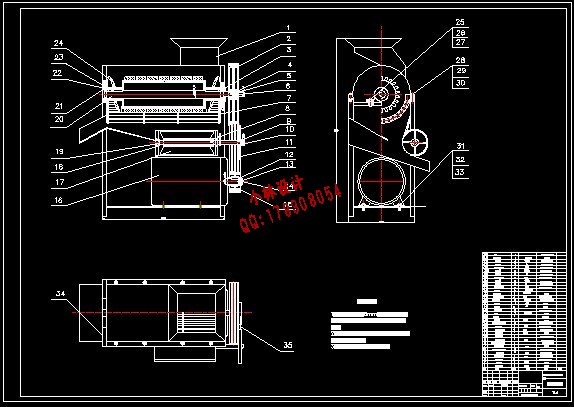

玉米脱粒机的设计

摘 要:长期以来我国玉米脱粒机主要是以打击原理对玉米进行脱粒,导致玉米脱粒过程中玉米的破碎率偏高,不仅降低了其价值,也对其生产效率与农民朋友的收入造成很大的影响。针对我国玉米脱粒现状,对现有玉米脱粒机进行改进设计很有必要。本设计一改传统钉齿脱粒方法,采用挤搓式原理用板齿进行脱粒,板齿呈螺旋均布便于脱粒与排出玉米芯。清选机构采用风机与分离筛,能很好的将玉米籽粒与杂物分离。

关键词:玉米;脱粒机;板齿

The Design of Corns Threshers

Abstract:For a long time,our corn shellers machine using principle of hitting to threshing,which leads to a high breakage rate.It not only decreas the value of corn ,but also has a great influence on it’s production efficiency and the income of farmer. In view of the current situation of the corn threshing in our country,improvement is in the need for corn shellers’machine. This design change our traditional method,which adopt principle of keading that using plank-tooth to threshing,the plank-tooth for threshing is arranged in spiral shape which is convenient to thresh corn and discharge core of corn,Construction of selective machine adopts fans and the separate shifter,which can separate of the corn and sundries.

Key words:corns;shellers machine;plank-tooth

目 录

摘要………………………………………………………………………………1

关键词……………………………………………………………………………1

1 前言……………………………………………………………………………2

2 玉米脱粒机的总体构造………………………………………………………3

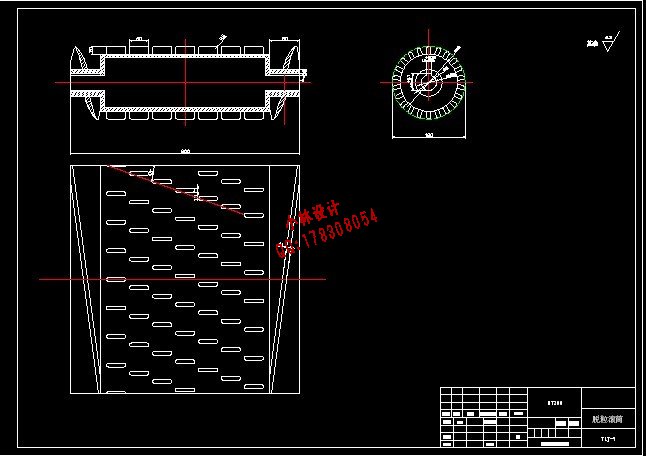

2.1 脱粒机构……………………………………………………………………3

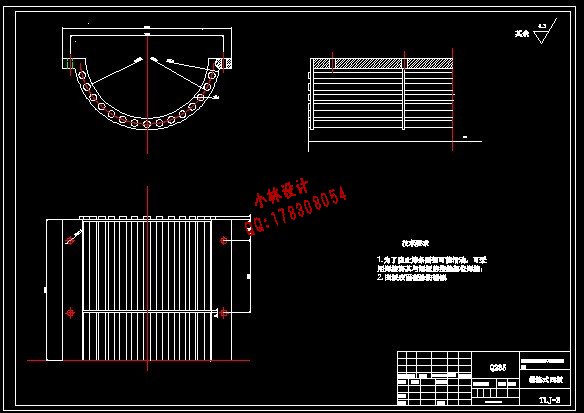

2.2 筛选机构……………………………………………………………………3

2.3 清选机构……………………………………………………………………4

2.4 机架…………………………………………………………………………4

3 玉米脱粒机的设计………………………………………………………………5

3.1 电动机的选择………………………………………………………………5

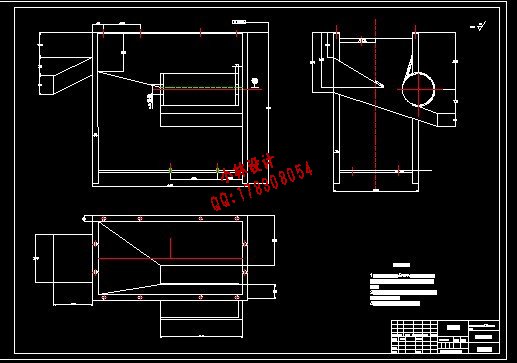

3.2 V带传动的计算……………………………………………………………6

3.2.1 确定传动装置的传动比…………………………………………………6

3.2.2 确定计算功率…………………………………………………………6

3.2.3 确定V带型号…………………………………………………………6

3.2.4 确定带轮直径与验算速度……………………………………………6

3.2.5 确定V带中心距与基准长度…………………………………………6

3.2.6 验算包角………………………………………………………………7

3.2.7 计算V带根数…………………………………………………………7

3.2.8 计算初单根V带拉力最小值…………………………………………7

3.2.9 计算压轴力……………………………………………………………8

3.3 带轮的设计………………………………………………………………8

3.3.1 带轮材料选择…………………………………………………………8

3.3.2 主动带轮设计…………………………………………………………8

3.3.3 从动带轮设计…………………………………………………………9

3.4 轴的结构尺寸设计……………………………………………………………9

3.4.1 传动轴的选择…………………………………………………………9

3.4.2 确定轴的直径长度…………………………………………………10

3.4.3 轴上载荷计算………………………………………………………11

3.4.4 校核轴的长度………………………………………………………13

3.5 轴承的选用……………………………………………………………………13

3.6 键的选择与计算………………………………………………………………14

3.6.1 键的选择……………………………………………………………14

3.6.2 键的强度验算………………………………………………………14

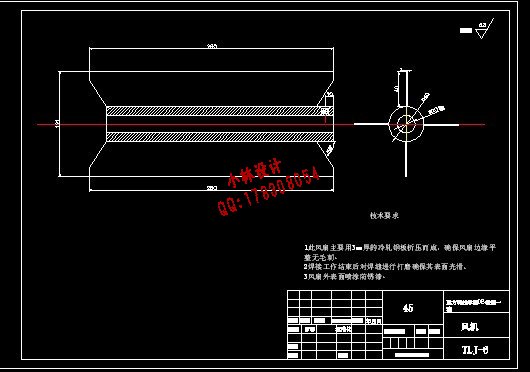

3.7 风机的选用……………………………………………………………………14

3.7.1 风速的计算…………………………………………………………14

3.7.2 受力分析……………………………………………………………15

4 结论…………………………………………………………………………………16

参考文献………………………………………………………………………………16

致谢……………………………………………………………………………………17

附录……………………………………………………………………………………17

|