|

|

|

|

设计名称 |

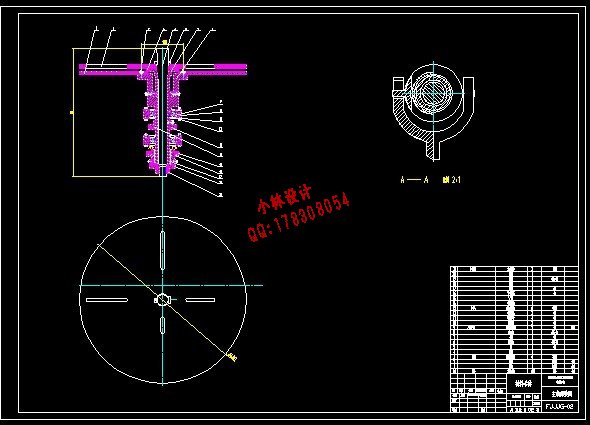

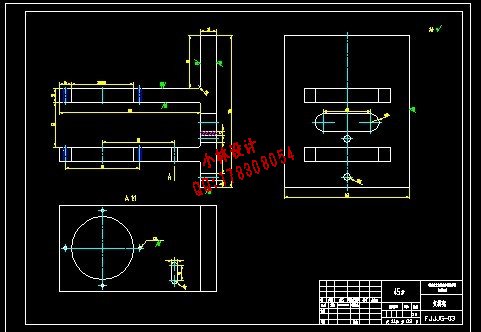

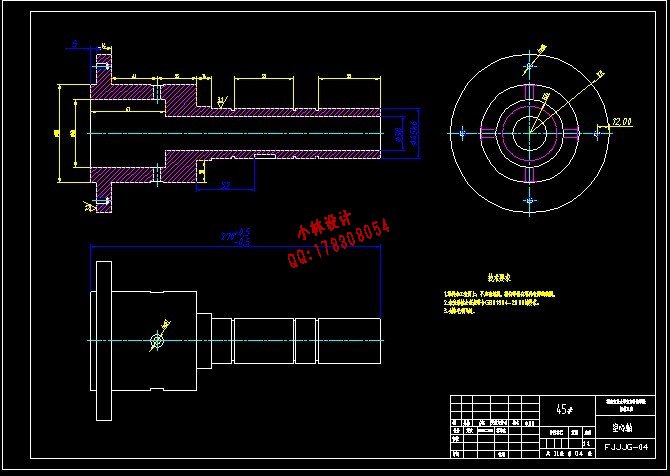

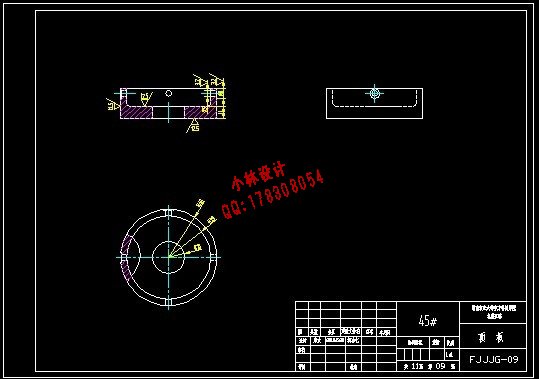

复卷机整机结构设计 |

|

|

设计编号 |

B086 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

20000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

开题报告一份 复卷机整机结构设计

摘 要:本文针对塑胶薄膜复卷机的机械结构部分进行了设计与说明,对于传统大型塑胶薄膜分切机分切之后不能保证宽度在30毫米以下的材料端面平整度的问题,采用本机器进行二次加工,从而达到客户要求。 The Design Of Rewinding Machine Structure

Abstract: This paper plastic film rewinding machine mechanical structure of the design and that part, to traditional large plastic thin film cutting machine after cutting and cannot guarantee the width of the material under 30 mm face the problem of flatness, using the machine in a second process, so as to achieve the requirements of customers.

目 录

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1