|

|

|

|

设计名称 |

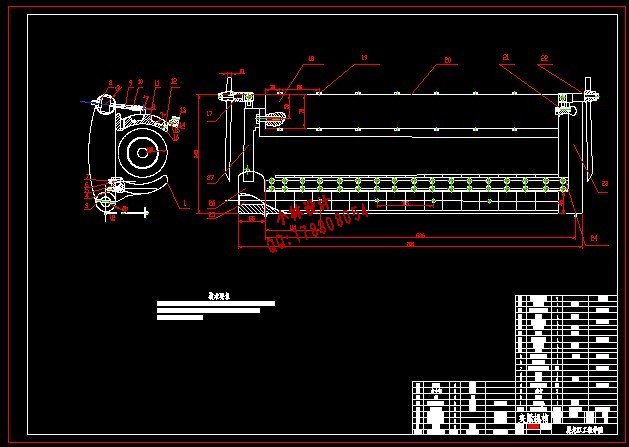

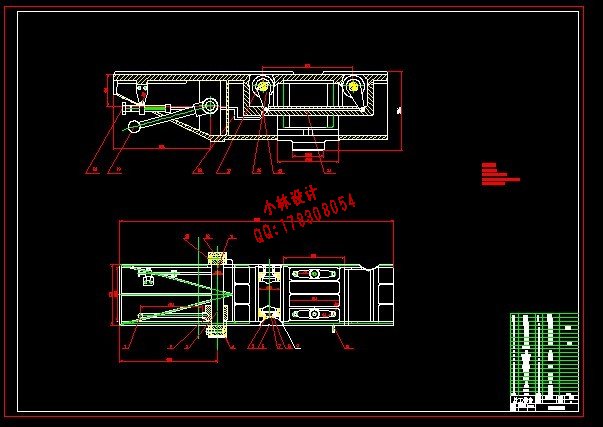

木工专用四面刨床的结构设计 |

|

|

设计编号 |

C054 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

18000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

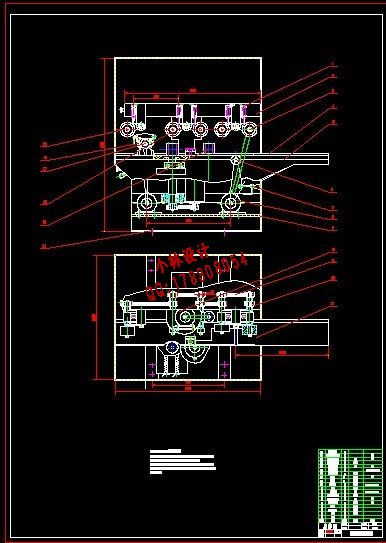

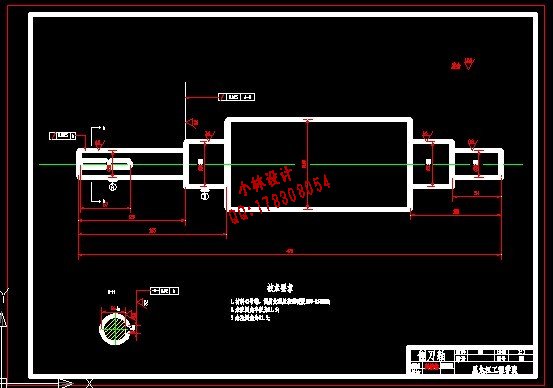

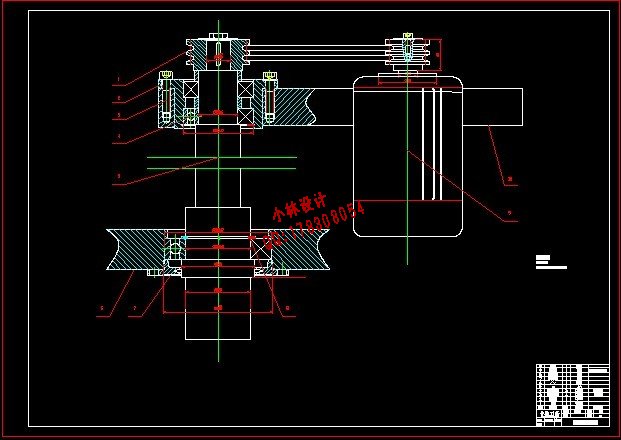

CAD版本图纸,共8张: ………… 摘 要 文章介绍了专用四面刨的的发展状况及其发展前景,联系了当前木工四面刨机床的市场现状,探讨的技术创新对木工四面刨机床的发展的作用,为了当前市场的需求专用四面刨更受到人们的青睐,本文主要是针对四面刨的活动平台、固定平台,升降机构、送料机构、切削机构的设计并介绍了一些有关当今四面刨遇到的问题及其解决办法,四面刨床主要是由床身、工作台、切削机构、进给机构、压紧装置、导板及操纵机构等零件组成。优秀的四面刨一般都是结构紧凑,工作台面镀硬络,经久耐用的。并且主轴特殊加工,精度要好。送料系统,最好是采用无级调速机构,送料辊与减速机构之间用万向节联结传动,才能传动平稳,送料才能强劲有力。进入了二十一世纪以后随着城市化进度的推进,人们对适于加工各种木料、木质板、四面开榫的地板块或木线条的加工有了更深层次的需求,而木工四面刨机床的应运而生恰恰满足了此种需求。 关键词: 四面刨;木工专用机械;机床;木料加工;活动平台;

ABSTRACT In this paper, four side blade is surrounded by a dedicated development and its development prospects, woodworking links on all sides of the current market situation planing machine to explore the technical innovation of woodworking machine surrounded by the role of the development of machine tools, in order to present the needs of the market more by special machine on all sides people's favor, this article is mainly directed against the activities of the platform surrounded by four sides blade, a fixed platform, body movements, body feeding, cutting the design of institutions and introduced the plane is surrounded by some of today's problems and their solutions, is surrounded mainly by the planer bed body, table, cutting body, feeding mechanism, clamping device, guide plate and the manipulation of body parts and other components. Plane is surrounded by fine are usually compact, working hard surface plating network, long-lasting. Spindle and special processing, accuracy is better. Feed system, it is best to adopt stepless speed regulation body, feed rollers and the slowdown between the transmission link with universal joints in order to drive steady, strong in order to feed. Into the twenty-first century with the advance of the progress of urbanization, it is suitable for processing on a variety of wood, wood-based panels, surrounded by open land mortise plate or wood with a deeper level of processing demand, and the wood on all sides planing machine came into being precisely to meet such demand. Key words:four sides bladespecical of Woodworking machine; engine bed;lumber processing ;ram bolster ;

目 录 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1