|

设计描述:

文档包括:

说明书一份,39页,19000字左右.

CAD版本图纸,共9张:

…………

摘 要

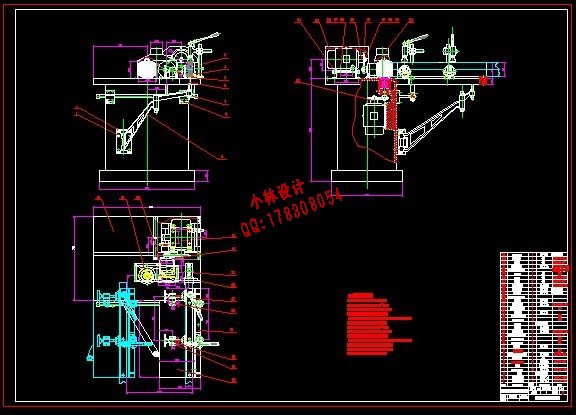

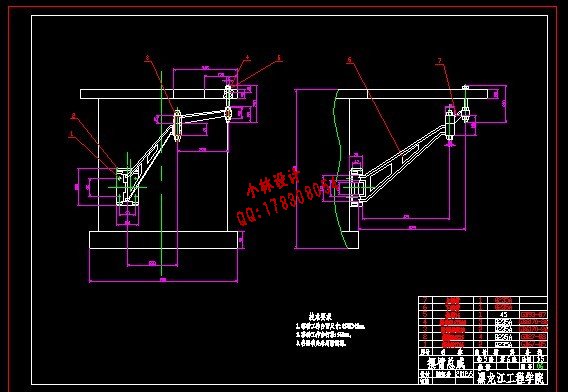

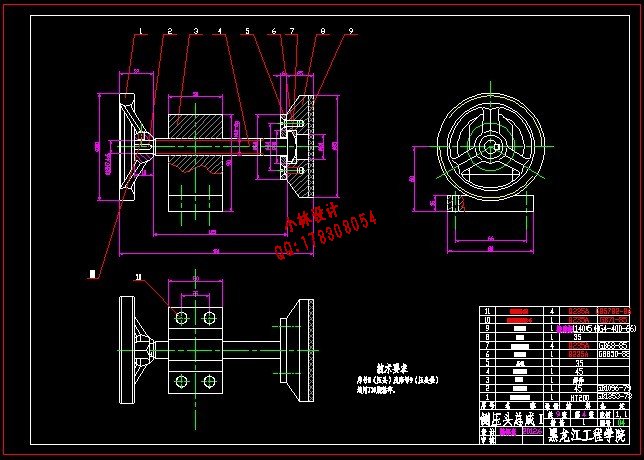

本次设计的指接机端面铣削部分是应用于普及型欧式木窗加工的专用设备,通过指接技术降低类似于欧式木窗的木工产品的生产成本,提高其市场竞争力。

通过对国内外指接设备的分析,在考虑生产成本的基础上,设计了能够满足一般指接需求的设备,并根据较小尺寸对刀具系统进行了完善,使本机床的刀具系统适用较小截面尺寸的木工产品的指榫加工。刀具主轴转速较高,并承受一定的扭矩,文中对其进行了受力分析,确保其在生产中的安全性,同时对其附属部分,如带传动和轴承等进行了校核计算。木材原料夹紧机构采用弹簧压紧,对弹簧力进行了分析,确保在最省力的情况下使木材原料顺利加工。

本题目从生产实际出发,为小径木材指榫加工设计关键设备,对现有的指接机进行改进设计,降低指接生产线成本,使指接技术得以普及。对于我国中小型木工企业的生产改型和技术革新有重要的意义。

关键词:木材;指接;指榫;欧式木窗;木工机械

ABSTRACT

The machine that we designed is a milling installation which is used for the machining of the popularized western-style wooden window. By applying this kind of knowledge, we could reduce the production costs of those products as western-style wooden window and enhance its competitive power.

Through the analysis of both the domestic and the foreign tenoners and on the basis of the consideration of its production costs, we have designed this kind of equipment which could meet the need for the joint of general tenon need raw materials and have made approve-ments to its tool system. Through this change, we have made its tool system more applicable for the joint of those products in smaller section size. The tool’s primary shaft works in higher rotational speed and withstands certain torque. We have carried out the force analysis in this article to make sure its security and have made checkouts to its accessorial parts, such as transmission belt and transmission shaft and so on. Through the analysis of the spring force, we uses the spring to compact in the lumber raw material jig system to make sure that the lumber raw materials could clamp smoothly in the situation which uses the minimum forces.

Combined from infact of product, this topic is set up both for the design of the key equipments which are used for the machining of this small materials and to make approvements to the existing tenoners so as to reduce the costs of the connect production line and to make this technique popular. With regard to our middle and small carpentry enterprise's production modification and technical innovation, this design has quite a vital significance.

Key words:Lumber; Connect; Tenon; Western-style wooden window; wood working machineny

目 录

摘要 I

Abtract II

第1章 绪论 1

1.1指接技术综述 1

1.2指接设备的研究意义 1

1.3木工机械的国内外发展综述 2

1.3.1木工机械产品的现状 2

1.3.2木工机械发展趋势 2

1.4指接概述 4

1.4.1指接工艺简介 4

1.4.2指接的特点 5

1.4.3指接材的种类 5

1.4.4指榫的加工方法 5

1.4.5指接机床的使用及加工缺陷的调整 6

1.4.6影响指接材质量的因素 8

1.4.7指接材质量评定与检验 9

1.4.8指接刀简介 10

第2章指接机切削部分的设计方案 13

2.1切削部分的设计任务 13

2.2切削部分的主要工作结构 13

2.3指接机的开榫原理及工作方式 13

2.4切削部分的设计方案 14

2.4.1机床的设计方案 14

2.4.2工作要求 14

2.4.3产品的用途 15

2.4.4工段的生产制度和主要经济指标 15

2.5本章小结 15

第3章 端铣系统的设计计算 16

3.1电动机的选择 16

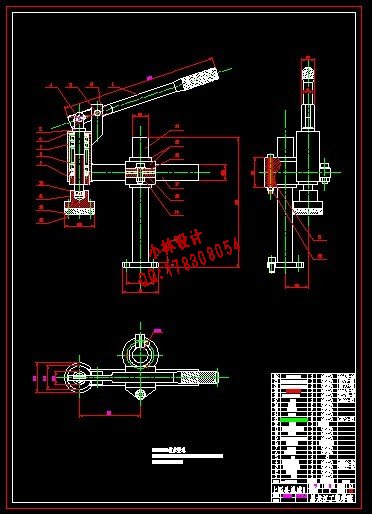

3.2轴的设计计算 17

3.2.1估算轴的基本直径 17

3.2.2轴的结构设计 17

3.2.3轴的受力分析 18

3.2.4按当量弯矩校核轴的强度 19

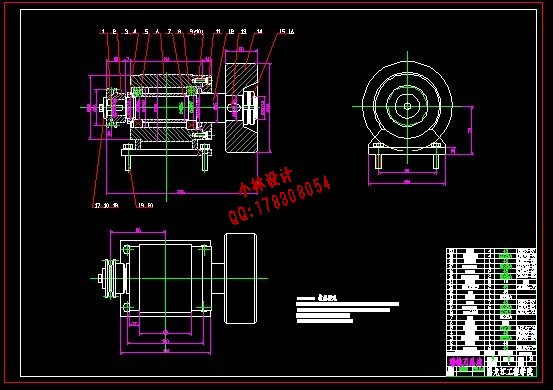

3.3带传动的设计计算 23

3.4轴承的选择与计算 25

3.5平键联结的强度计算 27

3.6本章小结 27

第4章 指接系统的设计计算 28

4.1电动机的选择 28

4.2主轴的设计计算 28

4.2.1估算轴的基本直径 28

4.2.2轴的结构设计 28

4.2.3按当量弯矩校核轴的强度 30

4.3带传动的设计计算 34

4.4轴承的选择与计算 38

4.5平键联结的强度计算 38

4.6本章小结 38

第5章 压紧机构的设计计算 39

5.1压紧机构的结构设计 39

5.1弹簧部分的计算 39

5.2本章小结 42

结论 43

参考文献 44

致谢 46

|