|

设计简介 |

设计描述:

文档包括:

Word说明书1份,共36页,约16000字

CAD版本图纸,共11张

目 录

1前言 1

2组合机床总体初步设计 2

2.1组合机床工艺方案的制定………………………………………………………..2

2.1.1切削用量的计算 2

2.1.2切削力、切削扭矩及切削功率计算 4

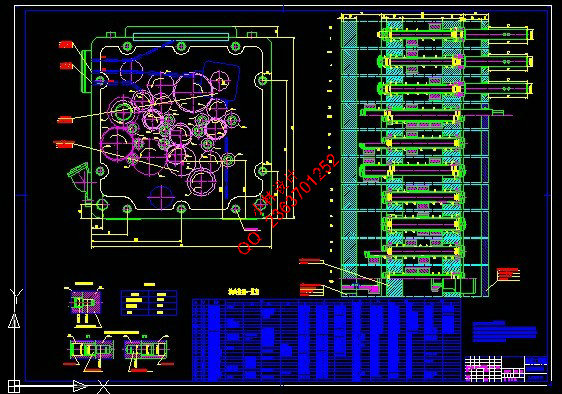

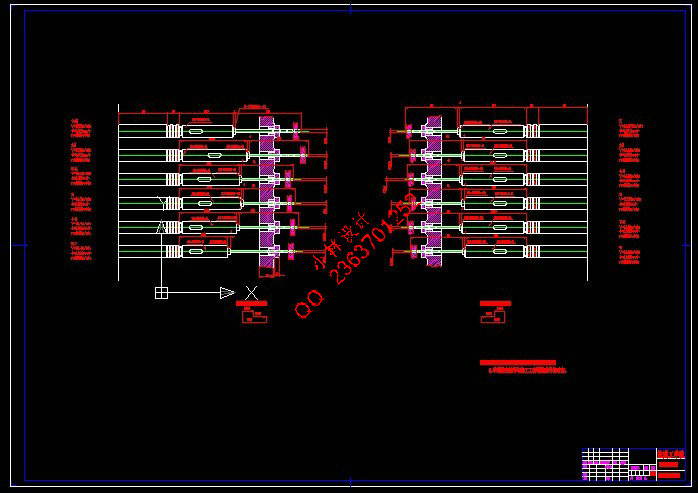

2.2 组合机床总体设计—三图一卡…………………………………………………5

2.2.1 被加工零件工序图 5

2.2.2加工示意图 6

2.2.2.1刀具的选择 6

2.2.2.2导向装置的选择 7

2.2.2.3各主轴直径的确定 7

2.2.2.4选择接杆 8

2.3机床联系尺寸总图………………………………………………………………..8

2.3.1动力箱型号的选择 8

2.3.2动力滑台导轨型式 9

2.3.3确定机床装料高度H 10

2.3.4确定夹具轮廓尺寸 10

2.3.5确定中间底座尺寸 10

2.3.6确定多轴箱轮廓尺寸 10

2.4机床生产率计算卡………………………………………………………………11

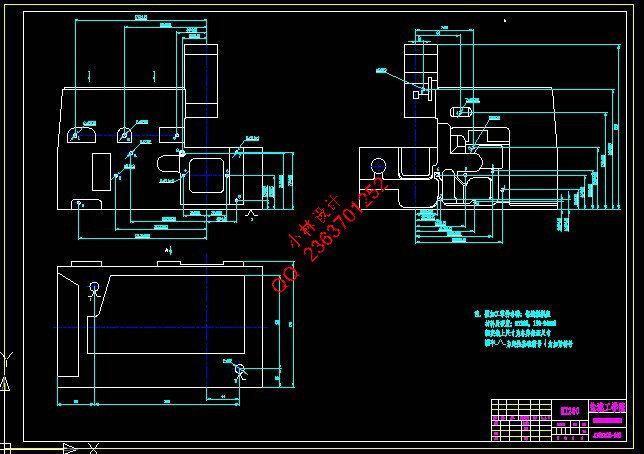

3组合机床多轴箱设计(左主轴箱) 14

3.1绘制左主轴箱设计原始依据图…………………………………………………14

3.2主轴型式和直径、齿轮模数的确定……………………………………………15

3.3主轴箱传动系统的设计与计算…………………………………………………15

3.4多轴箱坐标计算…………………………………………………………………17

3.4.1驱动轴、主轴的坐标计算 18

3.4.2计算传动轴的坐标 18

4零件强度校核 21

4.1齿轮校核…………………………………………………………………………21

4.1.1校核齿根弯曲疲劳强度 21

4.1.2校核接触疲劳强度 22

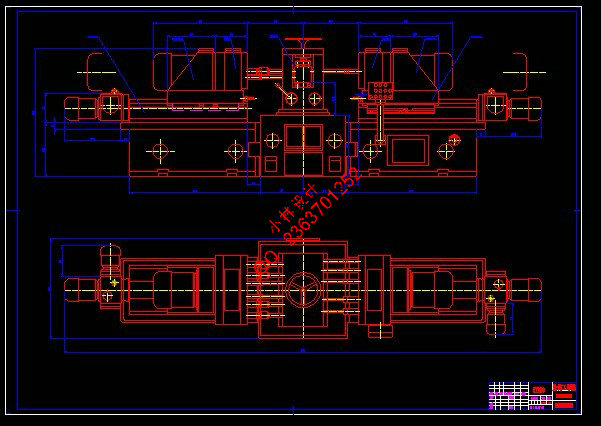

4.2传动轴直径的确定和轴的强度校核……………………………………………22

4.2.1轴的直径的确定 22

4.2.2轴的强度校核 23

4.3轴承和键的校核…………………………………………………………………26

4.3.1键的校核 26

4.3.2轴承的校核 27

5主轴箱体附件的选择设计 28

5.1分油器……………………………………………………………………………28

5.2油杯………………………………………………………………………………28

5.3油塞………………………………………………………………………………28

5.4叶片泵的设置……………………………………………………………………28

6结论 29

参 考 文 献 30

致 谢 31

附 录 32

包缝机机座孔钻孔组合机床总体及左主轴箱设计

摘 要:本课题为包缝机机座钻孔组合机床总体及左主轴箱设计。该机床设计主要分为总体设计和部件设计两部分。在全面了解被加工零件的结构特点、加工部位和技术要求等基础上,首先完成了组合机床的总体设计。具体内容是在确定总体方案的基础上,绘制出三图(被加工零件工序图,机床联系尺寸图,加工示意图)和生产率计算卡。本课题的重点是对左主轴箱的部件设计,首先,在完成组合机床总体设计的基础上,主要完成拟订了主轴箱的传动路线;然后,根据绘制出的主轴箱原始依据图,确定了具体传动方案,应用最优化方法布置齿轮,确定传动参数,设计了轴的结构;最后,进行齿轮、轴承等相关零件的强度校核计算。在满足加工精度的条件下,本方案采用液压滑台来实现进给运动。设计过程中尽量采用了标准零部件,设计出的组合机床结构简单,操作方便,加工精度高,减轻了劳动强度,提高了加工效率,具有较好的经济性和适用性。

关键词:组合机床;钻孔;左主轴箱

Package combination of sewing machine base bored and the design

of the left overall machine tool spindle box

Abstract: The topic for the package combination of sewing machine base bored and the design of the left overall machine tool spindle box.To improve the machining efficiency and to satisfy the processing requirements, the combine machine-tool was designed for drilling and boring the body of the R180 diesel engine cylinder with three facing set. The focal point of this topic is the total design and the design of the right headstock. Basing on studying comprehensively the components in structure characteristic, processing spot and specification and so on, the overall design of the combine machine-tool was completed. Its concrete content is to finish three drawings (process components working procedure chart, engine bed relation dimensional drawing, processing schematic drawing) and the productivity computation card on the foundation of the overall plan. The key of this modular is the right headstock part design. Firstly ,On the basis of completing the total design of machine tool system, the driving route of the headstocks were drawn up. Then according to headstock primitive basis chart and the methods of optimization, the concrete transmission plan was determined, the cogwheels are disposed, the driving parameter were determined. At last, the structure of principal axis were designed and the strength of parts are checked such as the cogwheels and the axletree. Under the condition of satisfying the processing precision, the liquid operated sliding table is used for realizing the movement. This design uses the standard headstock. The headstock uses standard details. This modular mechanical tool has such advantages: high efficiency, low cost, high processing precision, easily operated and it reduces the worker’s labor intensity, and enhances the productivity.

Key words: Modular machine tool; Bored; Left spindle box

|