|

设计简介 |

设计描述:

文档包括:

Word说明书1份,共32页,约16000字

CAD版本图纸,共10张

目 录

1 前言 1

2 涡流选粉机的总体设计 2

2.1 粉磨系统的工艺流程分析 2

2.2 涡流选粉机的分级原理 3

2.3 涡流选粉机的构造及工作原理 5

2.4 涡流选粉机的性能特点及应用 7

2.5 涡流选粉机的主要参数选择 7

2.6 涡流选粉机传动方案设计 8

3 涡流选粉机零部件设计 10

3.1 电机选择和传动部件设计 10

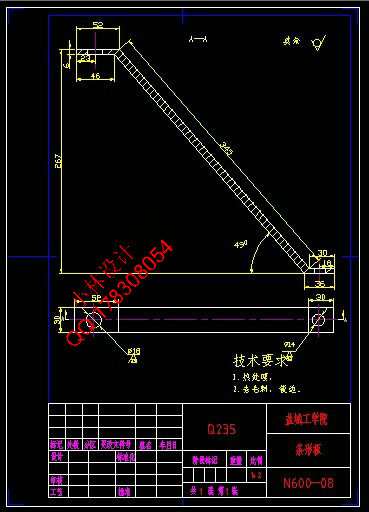

3.2 锥齿轮的设计及其校核计算 11

3.3 传动轴的设计及其强度校核 15

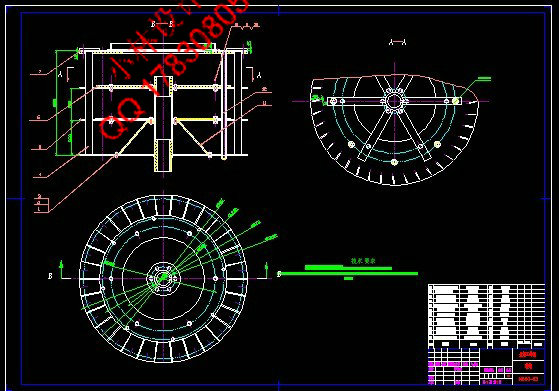

3.4 撒料盘和导向叶片的设计 18

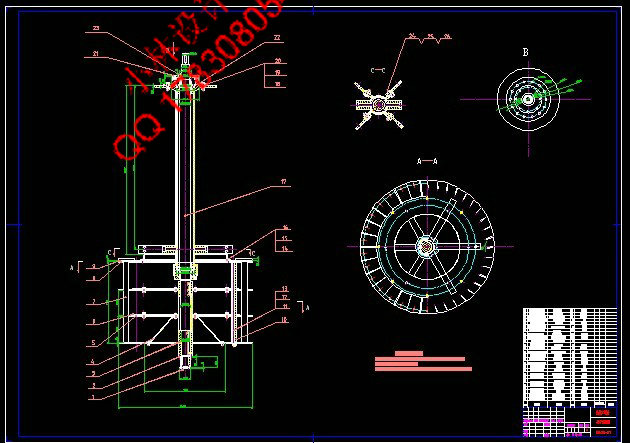

3.5 转子部件的设计 20

3.6 壳体的设计 21

3.7 转子平衡及轴上零件的固定 21

4 设备的制造和安装要求 23

4.1 制造要求 23

4.2 安装要求 23

5 设备的的操作、维护及检修 25

5.1 设备的操作和维护 25

5.2 设备的检修及注意事项 25

6 结论 26

参考文献 27

致 谢 28

附 录 29

N600高效涡流选粉机设计

摘 要:本课题是N600高效涡流选粉机的设计。设计基于日本小野田公司研发的O-SEPA涡流选粉机,并借鉴了当前在生料粉磨中应用较为广泛的新型选粉机。

首先进行了选粉机的总体设计,包括规格尺寸的确定、主轴功率的确定以及传动方案的确定。然后进行了选粉机零部件的设计,包括主轴、撒料盘、导向叶片以及笼型转子等的设计。同时进行了电动机、减速机和轴承的选型。最后进行了总体与部分之间的衔接技术构造。

在设计中通过调整导向叶片的角度及涡流调整装置,并配合分级效率和生产能力,得到最适当的配置,从而实现粉体分级,并且生产效率高,动力消耗少。另外通过调整导流叶片角度、涡流调整范围、分隔板张数三要素,并考虑了分级效率与生产能力,从而使选粉机达到最佳的分级效率。

设计的选粉机满足了运转平稳、工作可靠、结构简单、装卸方便、便于维修、调整等要求。

关键词:选粉机;导向叶片;分级效率;生产能力;笼型转子

Design of N600 efficient-eddy current separator

Abstract: This is the design of N600 efficient-eddy current separator,The design is based on the the O-SEPA eddy current separator which is researched and developped by Onoda company in Japanese and drawed lessons from the new type of separator which applied widely in raw material mill at present.

First, it is going on the overall design of the separator, including the design of the specification sizes, spindle powers and transmission program. And then,it is the design of the parts, including the design of spindle, scattered disk, guide vanes, rotor cagee and so on. Simultaneity,it is going on the selection of the motor, reducer and bearing. Finally, the linking of total and parts must be considered.

In the process of this design,it can get the most appropriate configuration with hierarchical efficiency and production capacity by adjusting the angle of the guide vane and the vortex,so that it can make the powers classifications and production efficiency is high and it consumes little energy. In addition, it is to adjust the angle of the guide vane, the range of the vortex adjusting and the number of separated panel taking into account the hierarchical efficiency and production capacity so that the separator can achieve the best classification efficiency.

The designed separator meet the following requirements:smooth operation, reliable, simple structure and handling convenience, ease of maintenance and adjustment.

Key word: separator; guide vane; hierarchical efficiency; production; capacity

|