|

设计简介 |

设计描述:

文档包括:

Word说明书1份,共40页,约20000字

CAD版本图纸,共5张

托盘输送机设计

摘要:

现代企业的生产流水线一般都采用国际的先进的流水线。与生产相配合的运送系统要以至相适用。在生产压力的作用下,需要更加现代输送系统。许多企业的物流水平还是停留在人工搬运的原始状态,为了改变这种人员劳动强度大现状,设计垂直输送机来代替人工从高楼搬运到地面的高强度工作。有利于人员的身心健康和寿命。

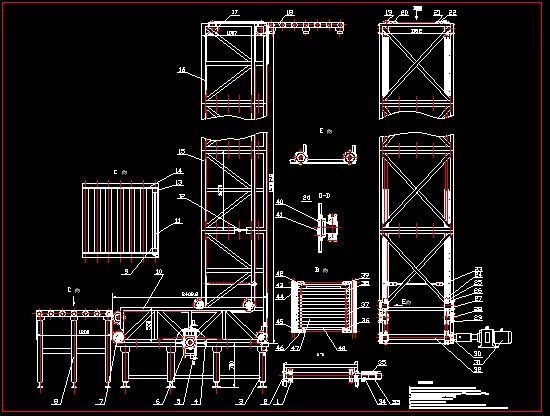

本文概述了输送机的工作原理,对常用输送机进行了说明,并详细分析了各自的特点,然后针对各种方案的优缺点,设计了适用范围比较大的输送机,按其工作方式说明输送系统所涉及各个零件的参数选取依据和连接方法,最后得出整个系统的装配图。

垂直输送机还可以搬运人员无法搬运的物品,而且在环境保护方面有利的,在生产方面可以提高劳动生产率,改善生产环境,降低生产成本,降低劳动强度。

从垂直定向输送既自身内部的特点:机构简单、制造成本低、高效率连续垂直输、送占地面积少、安全可靠、自动输入和输出、可双向运行、全自动控制,来分析可以证明设计制造垂直定向输送机是有利于企业的生存和命运。

关键词:输送机 输送系统 垂直定向

Pallet conveyer design

Abstract:

Modern enterprise production lines typically use the international advanced assembly line. Combined with production of transport system which is suitable to that. The effects of stress in production, need more modern transportation system. Many enterprise logistics level or stay in artificial handling of the original state, in order to change this personnel labor strength present situation, the design vertical conveyor to replace artificial from tall buildings to the ground handling the high strength. To the physical and mental health of the staff and service life.

This paper summarizes the principle of work of the belt conveyor, belt conveyor to commonly used were explained, and detailed analysis of the features of the various solutions then for the advantages, disadvantages and design the application range of the big conveyor, according to the work involved explains conveying system of the various parts of the parameter selection basis and the connection method, and then the whole system of the assembly drawing.

Vertical conveyor also can carry personnel can't handle items, and in protecting environment beneficial, in production can improve labor productivity, improve the production environment, to reduce the production cost, the reduction of labor intensity. From the vertical orientation conveying both inside features: simple structure, low cost, high efficient manufacturing for vertical lose, send covers an area of less, safe and reliable, automatic input and output, two-way operation, automatic control, analysis can prove to design manufacturing vertical orientation conveyor belt conveyor is benefit to the enterprise's survival and destiny.

Key words: conveyor Conveying system Vertical orientation

目 录

第一章 绪论 1

1.1选题目的和意义 1

1.2本课题在国内外的研究状况及发展趋势 1

1.3 主要研究内容 1

第二章 概述 3

2.1垂直托盘式输送机 3

2.1.1 托盘式输送机的分类 3

2.1.2 应用范围及主要优缺点 3

2.1.3 布置形式 4

2.1.4 主要部件 4

2.2底板 5

2.3.驱动装置 5

2.4张紧装置 5

2.5机架 5

第三章 设计方案的确定 6

3.1设计目的 6

3.2设计方案 6

第四章 设计计算 9

4.1确定链条参数 9

4.1.1 链节参数 9

4.1.2 输送功率 9

4.1.3 链条长度 11

4.2确定链轮及轴的参数 12

4.2.1 链轮的参数 12

4.2.2 链轮轴的参数 13

4.3 确定运输单元参数 15

4.4 确定托板参数 16

4.5 确定连接器 19

4.6 确定链条轴销 20

4.7 确定水平滚动装置 21

4.8确定轴承、轴承盖及润滑 22

4.8.1 确定轴承: 22

4.8.2 确定轴承盖: 23

4.8.3 润滑方式及润滑油的选择: 23

4.9 确定电动机 24

4.10 确定机架 24

4.10.1 机架的结构选择 24

4.10.2 机架的制造和材料 25

4.10.3 机架的结构参数 25

4.11 确定联轴器 26

4.12 确定张紧装置 26

第五章 输送机安装与调整 28

5.1安装顺序 28

5.2 安装技术要求 29

5.2.1 机架的安装 29

5.2.2 轨道的安装 29

5.2.3 主要部件的安装 29

5.3 输送机的调整 30

总结 31

致谢 32

参考文献 33

附录 34

|