|

设计简介 |

设计描述:

文档包括:

Word说明书1份,共20页,约8000字

CAD版本图纸,共7张

摘 要

本课题是基于电子行业,纺织行业的绕线工序,传统行业中大部分依靠手工绕线对人员依赖程度高,导致与绕线工艺相关的绕线行业存在一些无法逾越的问题,首先在电子行业,激烈的竞争以及国内人力成本的逐步提高,导致一些企业利润相当微薄,再次由于磁环绕线工作枯燥乏味,工人流动性极大,从而导致绕线企业缺乏熟练的绕线工,容易产生误差,不能保证产品的高精度,例如在仪表加工行业中,手工绕制的线圈产品,误差相差三圈会导致一起的测量精度会降低0.01,使得产品不能达到万分之五的精准这直接用想到企业的生产效率与生产质量,因此开发自动绕线机成为制造业的一个新的机遇。

本课题主要针对绕线机的传动部分元件,利用Inventor对绕线机的传动装置零件进行三维实体建模,在进行绕线机的传动装置设计时,首先考虑的传动平稳,运动可靠问题,在使用过程中不能存在任何的安全隐患问题,使用简便、容易操作。

运用Inventor软件对设计出线机的传动装置零件进行装配,检查干涉情况,并运动仿真分析。

关键词:Inventor绕线机; 三维建模; 运动仿真

Abstract

This topic is based on the electronics industry, textile industry during the process, the traditional industry rely on hand to personnel during most of the dependent degree is high, cause and winding process related coiling industry has some not insurmountable problem, first in the electronics industry, the fierce competition and domestic the gradual improvement of the human cost, leading some corporate profits are lean, once again, because they can work during boring, workers liquidity is great, leading to coiling enterprise shortage of skilled work during, easy to produce the error, can't guarantee products of high precision, for example in the instrument processing industry, the coil products made by hand, are three laps will lead to the error of measurement accuracy together will reduce 0.01, make product can't reach five over ten thousand of the precise directly with the thought of enterprise production efficiency and production quality, and so develop automatic winding machine be manufacturing a new opportunity.

This subject mainly for coiling machine of the transmission part components, the use of coiling machine Inventor of the transmission parts for 3 d entity modeling, in coiling machine transmission device design, the first consideration of smooth transmission, sports and reliable, in use process can't exist any safety concerns, easy to use, easy to operate.

Using software to design qualification machine Inventor of the transmission parts assembly, check the intervene problem, and motion simulation analysis.

Key words: Inventor software; Autodesk maya; motion simulation。

目 录

摘要…………………………………………………………ⅠABSTRACT………………………………………………………………………………………… Ⅱ

1前言………………………………………………………………………………………………… 1

2总体方案设计……………………………………………………………………………………… 1

2.1曲柄摇杆三维建模………………………………………………………………………… 2

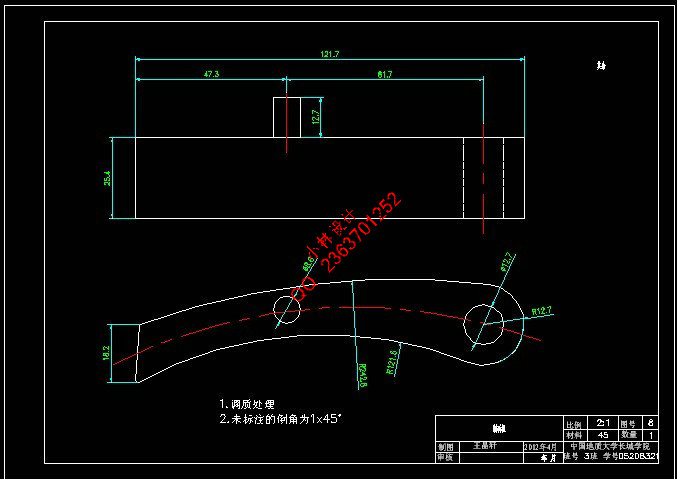

2.2连杆模型绘制……………………………………………………………………………… 3

2.3圆盘曲柄…………………………………………………………………………………… 3

2.4制动爪……………………………………………………………………………………… 4

2.5止动爪的模型构造………………………………………………………………………… 6

2.6棘轮的模型绘制…………………………………………………………………………… 6

2.7轴承与螺母的绘制………………………………………………………………………… 8

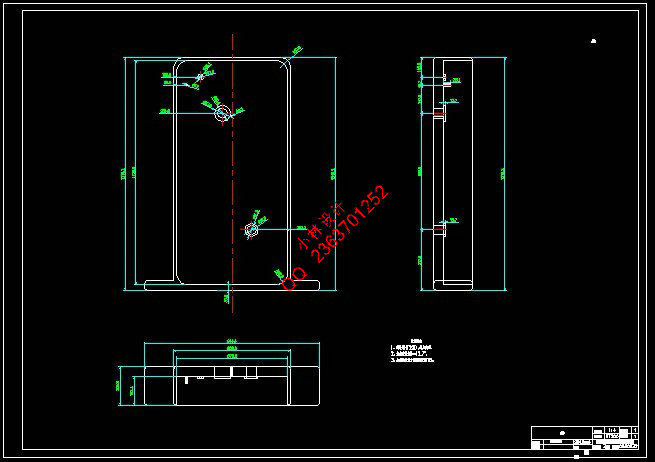

2.8箱体的建模过程…………………………………………………………………………… 10

3零件的装配………………………………………………………………………………………… 12

3.1装配相关技术……………………………………………………………………………… 13

3.2创建新零部件……………………………………………………………………………… 13

3.2.1结果类型控制…………………………………………………………………………13

3.2.2文件名称和位置………………………………………………………………………13

3.2.3默认BOM表结构………………………………………………………………………13

3.2.4虚拟零部件……………………………………………………………………………13

4运动仿真…………………………………………………………………………………………… 13

基本概况……………………………………………………………………………………13

5润滑与封闭………………………………………………………………………………………… 14

5.1 润滑…………………………………………………………………………………………14

5.2封闭…………………………………………………………………………………………14

5.3安全………………………………………………………………………………………… 14

6结论……………………………………………………………………………………………………15

参考文献…………………………………………………………………………………………………16

致谢………………………………………………………………………………………………………17

前 言

绕装机是金属导线生产中最后环节封装,完成家用电器,电机及工业电机线圈绕制的电工专用设备.

它主要目的是把生产出的金属导线缠绕成卷,便于运输。由于是生产的最后环节,所以一定要保证设备不会对产品构成破坏,也要求有记数系统以便于统计产量和方便销售。国外绕线机的线嵌设备已由电器自动控制发展到微机控制.有些还具备关键部位的状态监视和故障诊断功能.然而我国在这类设备的控制方面还基本上采用传统的电器控制,生产效率低,线圈绕制的质量差,属于半手工半自动的操作方式。

2 总体方案设计

|