|

设计描述:

文档包括:

word版设计说明书一份,共36页,约14000字

CAD版本图纸,共3张

六档箱体双面攻丝机床左主轴箱设计

摘 要

组合机床是一种专用机床,它是由系列化标准化的通用部件和按被加工零件的形状及加工工艺要求设计的专用部件组成。。组合机床随着生产力的发展,是由万能机床和专用机床发展而来的。

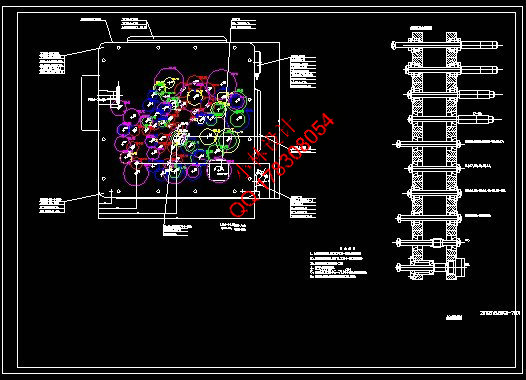

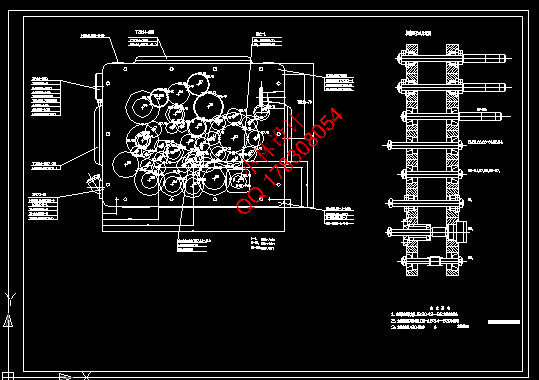

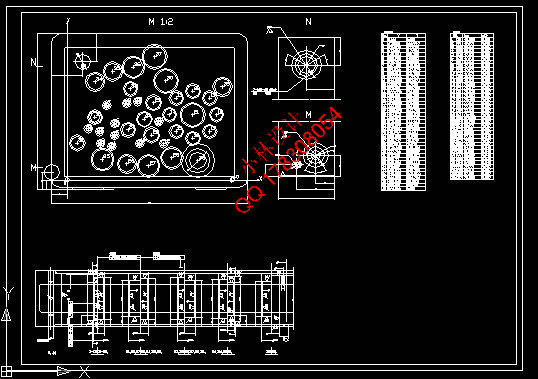

此次设计的目的就是设计一台攻丝组合机床,用于加工六挡箱 侧支架的12个孔。任务是六挡箱双面攻丝机床左主轴箱的设计。这次设计的内容有组合机床“三图一卡”,组合机床的简要设计,主轴箱设计及其液压系统设计,选择出机床总体及各部件的主要参数,画出液压系统图。主轴箱的设计是这次任务的重点,它是组合机床的重要部件之一。它是由通用部件,按照被加工零件的加工要求,根据专用要求设计的。

合理的安排每一根轴的的位置,选择合适的各级传动比,将动力和运动由电机或动力部件传给各工作主轴,使之得到要求的转速和转向从而实现对零件的加工。其次,合理安排各主轴和传动轴上齿轮所在的排数;合理布置进油口、放油螺栓、分油盘及油管的位置;确定主轴和传动轴的支撑方式和预紧方法也是非常重要的工作。

本文依据主轴箱的设计原则完成了对结构型式的选择及动力计算,传动系统的设计与计算,主轴箱总图设计,主轴箱坐标计算和液压部分的设计。

关 键 词:组合机床,主轴箱,传动轴,攻丝,齿轮

DESIGN OF VERTICAL HEADSTOCK USED IN THE DRILLING OF SIDE SUPPORT

ABSTRACT

The modular machine-tool is one kind of special purpose machine. It is composed by the general part and the special-purpose part. The general parts are designed according to the serialized standardization design. The special-purpose part is according to the machined and the processing technological requirement. The modular machine-tool is along with the productive forces development. It comes by the general purpose machine and the special purpose machine development.

The aim of our current design is to design a aggregate drill machine tool , which is used for processing the 12 holes in the stent of tractor. The task is the design of vertical headstock. This design involves the content that including the aggregate machine-tool’s a three charts card"、the designing of vertical headstock and its hydraulic system、the brief designing of aggregate machine-tool、choosing the overall engine bed and various parts main parameter and drawing the hydraulic scheme. The key point of present design is the vertical headstock designing. Theheadstock is one major components of aggregate machine-tool . It is designed by according to the special-purpose request. It is composed by the general part. It acts according to which is processed the components the processing request. It reasonably arranges each the position of axis. The all levels of velocity ratios is choosing suitably. The power and the movement bequeathed by it to the electrical machinery or the power part each work main axle. It enable each work main axle to obtain the request the rotational speed and changes thus realizes to the components processing. And, reasonably arranging rows between the main shaft and transmission gear; reasonably arranging the position of oil import ,oil-site, vitta, and oil bolt; determining the support way and preload methods between the principal axis and transmission shaft .It’s also my main task.

This article has completed in line with the headstock principle of design to the structure pattern choice and the power computation。Transmission system designing and computation、multi-spindle box assembly drawing designing and partial hydraulic pressure designing hydraulic pressure partial designs.

KEY WORDS:aggregate machine-tool , headstock, driving shaft,vertical,gear

目 录

前 言 1

第1章 组合机床概述 2

§1.1 组合机床简介 2

§1.2 组合机床的特点 2

§1.3 组合机床工艺范围及发展方向 4

§1.3.1 组合机床工艺范围 4

§1.3.2 组合机床发展方向 4

第2章 被加工零件工艺方案的制定 6

§2.1 零件分析 6

§2.1.1 零件的用途 6

§2.1.2 零件的技术要求 6

§2.2 工艺方案的制定 7

§2.3 组合机床切削量及切削力的确定 8

§2.3.1组合机床切削量的确定 8

§2.3.2组合机床切削力的确定 8

§2.4 主轴直径的确定和主轴箱所需动力计算 9

§2.4.1主轴直径的确定 9

§2.4.2动力箱的选用 9

第3章 侧支架立式主轴箱的设计 11

§3.1 主轴箱的基本机构及表达方法 11

§3.1.1 主轴箱简介 11

§3.1.2 通用主轴箱的组成 11

§3.1.3 通用主轴箱的通用零件 11

§3.2绘制主轴箱设计原始依据图 12

§3.3确定主轴结构型式及齿轮模数 13

§3.4主轴箱的传动系统设计 14

§3.4.1对主轴箱传动系统的一般要求 14

§3.4.2传动系统的设计与计算 15

§3.5主轴箱总图设计 27

§3.5.1 绘制主轴箱总图及补充加工图 27

§3.5.2主轴箱补充加工图设计 28

结 论 29

参考文献 30

致 谢 31

|