|

设计简介 |

设计描述:

文档包括:

word说明书一份,共35页,约17000字

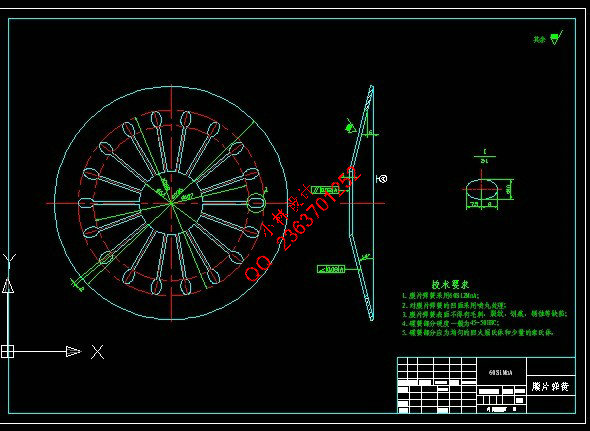

CAD版本图纸,共9张

PROE三维一套

[摘 要]

本论文主要目的是按照整车设计应达到的性能参数进行离合器的匹配设计。

离合器是传动系统中直接与发动机相连接的装置。它的作用是平稳接合、切断发动机和传动系之间的动力传递。离合器可以保证汽车平稳起步;避免变速器换挡时,轮齿间发生剧烈的冲击;防止传动系中各零部件由于过载而损坏。

膜片弹簧离合器相对于螺旋弹簧离合器有着一系列的优点:膜片弹簧的非线性特性使在摩擦片整个磨损过程中保证压盘受到压紧力基本保持不变,保证离合器工作性能更稳定;膜片弹簧的分离指起到分离杠杆的作用,这样,省去了多组分离杠杆装置,零件数目减少,质量也减轻;在满足相同压紧力的情况下,膜片弹簧的轴向尺寸较螺旋弹簧小,在有限的空间内便于布置,使离合器的结构更为紧凑;同时膜片弹簧是圆形旋转对称零件,平衡性好,在高速时,其压紧力降低很少。并且制造工艺水平的不断提高,膜片弹簧离合器越来越广泛运用在现在汽车中。

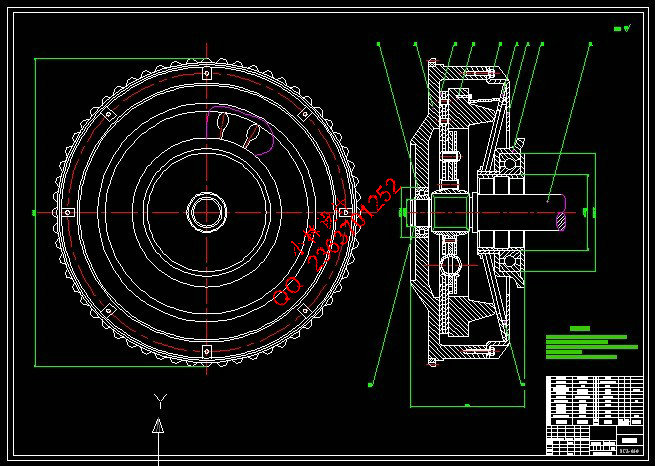

离合器主要由三部分组成:主动部分、从动部分和操作机构。作者设计思路按照这三个部分依次进行,设计过程简要概述如下:

1) 根据整车应达到一系列性能要求完成了汽车的总体设计。

2) 根据前面的汽车总体设计结果,对离合器基本尺寸、参数进行了选择。

3) 对离合器各零部件进行匹配性设计,并进行校核计算。

4) 对操纵机构的选型和设计。通过对机械式操纵机构和液压式操纵机构系统适用场合和优缺点的分析,选择液压式操纵机构作为该轻型汽车的操纵机构。

[关键词]:离合器 操纵机构 压盘 膜片弹簧 非线性弹性特性

Abstract

The paper mainly designs the fundamental parameters of the clutch to make better match to the total performance parameter requirement of the car.

The clutch is the friction device which is connected with the engine directly in the power train .Its purpose is to provide smooth engagement and disengagement of the engine from manual transmission. By means of the clutch, it can make the car reasonable and comfortable start , avoid violent shock while shifting the gears inside the transmission and prevent each parts of the power train from damaging because of overload.

Diaphragm spring clutch have some advantage over spiral spring clutch: During the whole abrasion of friction plate, the nonlinearity elastic property of diaphragm spring ensures the pressing force to the plate remaining practically unchanged, Therefore, the working performance is much more stability. The center portion of the diaphragm spring is slit into numerous fingers that act as release levers. As several groups of the separation devices leaves out, the number of parts and the total mass decrease to some degree; under the same requirement pressing force circumstances, the axial dimension of the diaphragm spring is shorter than the spiral spring, Therefore, the clutch can depose compactness in confined space; diaphragm spring is circular rotational symmetry part so that it can obtain good balance at high speed. Meanwhile, with the improvement of manufacturing process levels, diaphragm spring clutch application in modern cars is doomed to becoming much more popularity.

The dry clutch mechanism includes three basic parts: driving member, driven member and operating members. The author performs his paper just in accordance with this turns, the procedure sum up as follows:

1) According to the overall requirement of the car, the overall design is accomplished

2) Based on the former overall design outcome, the fundamental structure and parameters is to be selected.

3) By the best match principles, the author designs the various parts of diaphragm spring clutch appearance and material parameters .Through checking calculation and modification again and again, the results is good.

4) The operation device selecting and design. Compared the mechanical type control system with the hydraulic pressure type control system in strengths and weaknesses and application range, the author selects the hydraulic pressure type control system as the light-duty vehicle’s operation device.

[Key words]:Clutch Operating Mechanism Pressure plate Diaphragm Spring Nonlinearity elastic property

目 录

第一章 前言……………………………………………………………………… 2

第二章 离合器的结构设计…………………………………………………… 4

2.1 离合器的结构选择与类型………………………………………… 5

2.2压紧弹簧布置形式的选侧………………………………………… 6

2.3压盘的驱动方式…………………………………………………… 8

3.离合器的设计计算……………………………………………… 11

3.1 离合器设计所需数据………………………………………………12

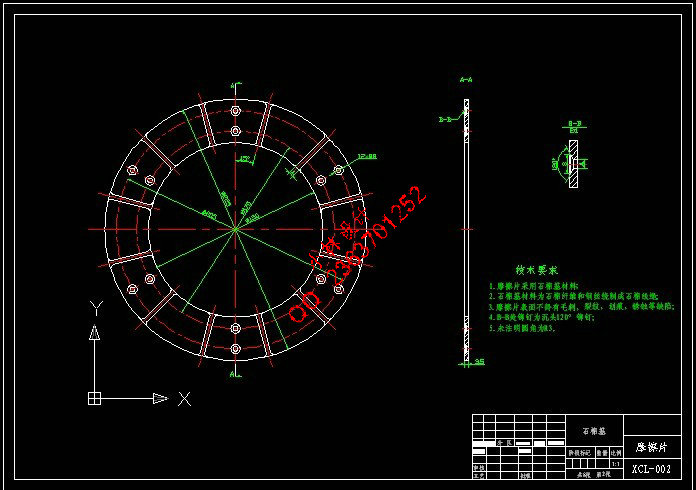

3.2 摩擦片主要参数的选择……………………………………………12

3.3 摩擦片基本参数的优化……………………………………………14

3.4 膜片弹簧主要参数的选择…………………………………………16

3.5 膜片弹簧的优化设计………………………………………………17

3.6 膜片弹簧的载荷与变形关系………………………………………18

3.7 膜片弹簧的应力计算………………………………………………20

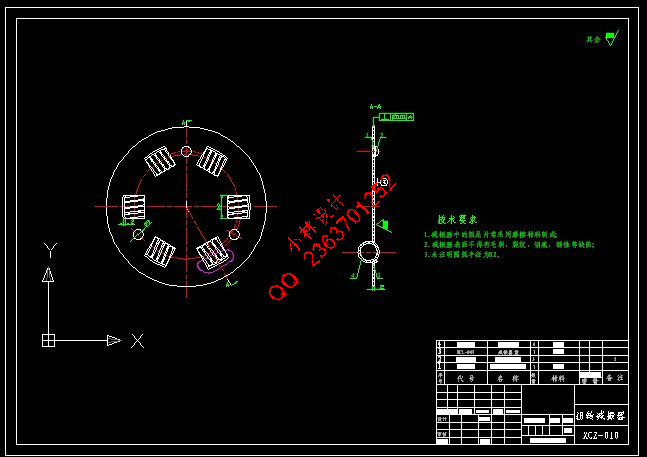

3.8 扭转减振器设计……………………………………………………23

3.9 减振弹簧的设计……………………………………………………25

3.10操纵机构……………………………………………………………26

3.11从动轴的计算………………………………………………………27

3.12从动盘毂……………………………………………………………28

3.13分离轴承的寿命计算………………………………………………29

3.14本章小结………………………………………………………………………30

参考文献………………………………………………………………………31

致 谢………………………………………………………………………32

|