|

设计描述:

文档包括:

word说明书一份,共46页,约22000字

CAD版本图纸,共4张

X6132经济型数控化改造

-------控制部分设计

内容摘要: 利用数控系统改造铣床是提高老设备利用率的一种重要手段。改造后的数控铣床,不仅适合加工椭圆弧面和凸轮曲面,而且大大地减轻了工人的劳动强度。

本文介绍了一种用单片机控制伺服电机的X6132万能升降台铣床的工作台的数控改造的半闭环控制系统设计方案。改造后的机床能利用微型计算机来控制直流伺服电机,驱动工作台进行X、Y、Z三个方向的进给运动,从而实现二轴联动,该半闭环控制数控系统由测速发电机来反馈伺服电机的速度,同时由感应同步器来反馈滚珠丝杠的角位移量,具有机床自动进给的功能。该系统可实现直线插补和圆弧插补,数控加工按轮廓编程,能自动适应刀具尺寸的变化。

关键词: 数控改造 X6132 半闭环控制

X6132 Economic Transformation NC

------Control part of the design

Abstract: It is implement the rebuilding of general machines to NC machines,it could increase work efficiency of old equipment. Rebuilt NC machines,not only process the oval of Arc-shaped face and the oval curved face,but also meanwhile alleviated the worker’s labor strength consumedly.

This text introduced a kind of all-powerful working panel lifter in X6132 miller that use the half that the number of the work set of the single servo electrical engineering in control in a machine control reforms to shut the wreath control system design project. Rebuilt NC machines making use of the microcomputer controls servomotors, the three axes in the X、Y、Z plane enters to reforms to sport mutually control with the servo electrical engineering in direct current, realize the two stalks contacting move, this half closed-loop control system makes the tachogenerator to feed back the servomotors’ speed and the respond synchronous machine feed back the ball screw-bar’s angular displacement, and designed to realize the machine bed enters automatically to of the number controls the device, the numeral control system adopts the half closed-loop control .The servo electrical engineering drives, can realize the straight line put to repair and put to repair with the arc. The number controls to process to press outline plait distance procedure but can adapt to the variety that knife have size.

Key Word: numerization rebuilding X6132 the half closed-loop control

目 录

前 言 1

正 文 6

1.总体设计方案的设计 7

1.1原来的X6132普通升降台铣床的用途 7

1.2总体设计任务 7

1.3总体设计方案 7

1.4、主传动系统的改造 10

1.4.1电气部分的改造 10

1.4.2机械部分的数控化改造 11

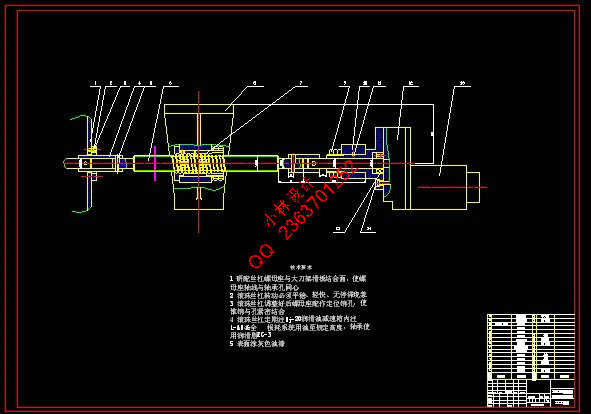

1.5给传动系统的改造 11

1.5.1改造设计要求 11

1.5.2进给传动系统的改造方案 11

1.6.数控系统的硬件与软件设计 12

1.7.改造后的布局及功能 14

2.控制系统的硬件设计 15

2.1单片机的选择 15

2.1.1 CPU的比较和选用 15

2.1.2存储芯片的选择 17

2.1.3 I/O接口芯片 17

2.1.4越界报警和急停电路 18

2.2伺服电机的驱动 19

2.2.1光电耦合电路 20

2.2.2PWM功率放大器电路 21

2.3检测装置 24

2.3.1测速发电机 24

2.3.2感应同步器 25

2.4实现机床自动进给的数控装置 26

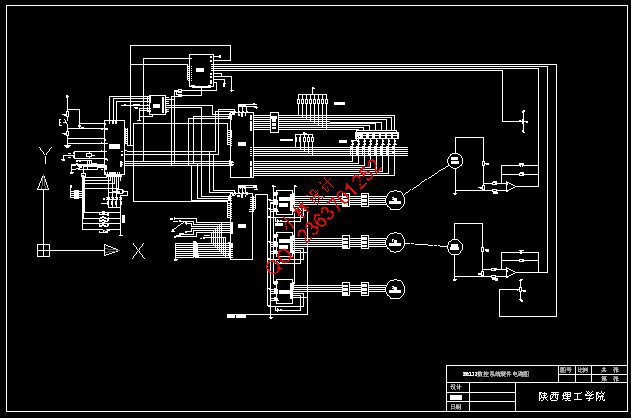

2.4.1自动进给数控装置框图 26

2.4.2总电路图 27

2.4.3 单元电路 28

3.软件部分的系统设计 30

3.1数控系统软件功能的实现 30

3.2数控系统的软件设计 33

3.2.1系统初始化 33

3.2.2 工作方式选择 33

3.2.3机床控制 34

3.3数控系统的软件设计举例 34

3.3.1 A/D转换电路的程序设计 34

3.3.2显示器显示程序 36

4.总 结 39

|