|

|

|

|

设计名称 |

普通X62W铣床的数控化改造设计【机+电】 |

|

|

设计编号 |

Z006 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

20000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

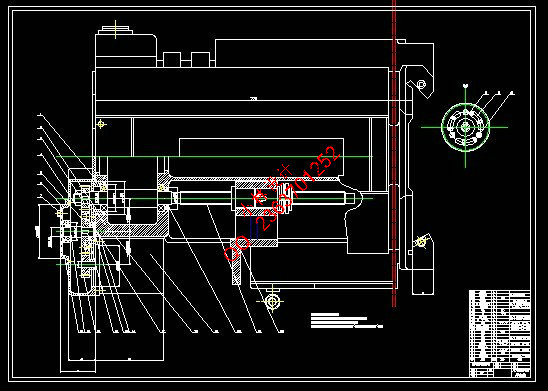

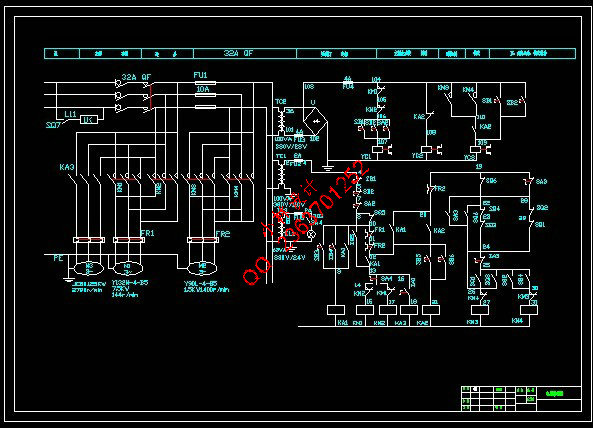

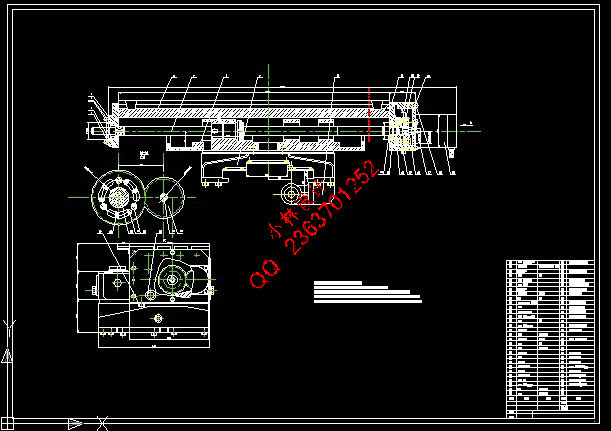

文档包括: CAD版本图纸,共5张

普通X62W铣床的数控化改造设计

ORDINARY X62W MILLING MACHINE ABSTRACT

I design of graduation project for" ordinary milling machine numerical control transformation design". For the machine tool design, I first want to design of machine tool technology research, consulting literature at home and abroad, on the basis of this, the application scope, performance index, scheme comparison and analysis. For universal machine I was referring to a large number of domestic and international relevant milling machine information, formulate the overall plan for the vertical milling machine.

KEY WORDS Numerical control transformation; position precision; stepping motor; ball screws; servo drive system |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1