|

设计描述:

文档包括:

word说明书一份,共33页,约20000字

CAD版本图纸,共12张

目录

摘要 1

Abstract 2

前言 3

1 蔬菜移栽机的研究发展 3

1.1国外移栽机械的研究概况 3

1.2国内移栽机械的研究概况 3

1.3移栽机械的主要类型 4

1.4移栽机械研究存在的问题及发展趋势 9

1.4.1移栽机械研究存在的问题 9

1.4.2移栽机械研究的发展趋势 9

2 悬杯式蔬菜移栽机的工作机理 10

2.1栽苗器整体的运动轨迹分析 10

2.1.1栽苗器整体的运动方程 10

2.1.2栽苗器的运动轨迹分析 11

2.2悬杯式蔬菜移栽机的主要特征参数 12

3悬杯式蔬菜移栽机的结构设计 14

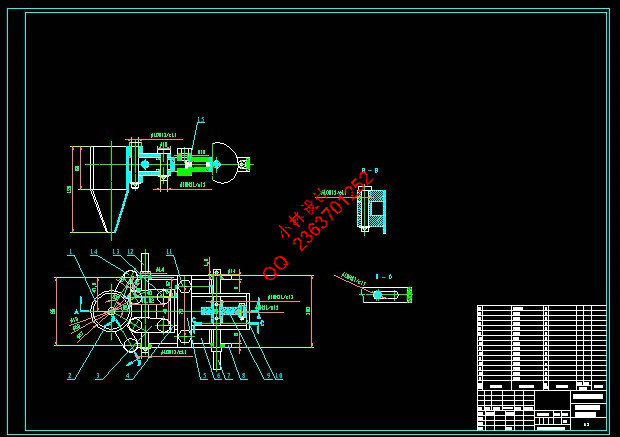

3.1整机结构与工作过程 14

3.1.1整机结构 14

3.1.2整机工作过程 15

3.1.3性能指标 15

3.2栽植单体的设计 16

3.2.1栽植轮 16

3.2.2悬杯式栽苗器 18

3.2.3开沟器 23

3.2.4覆土镇压轮 23

3.3传动系统 24

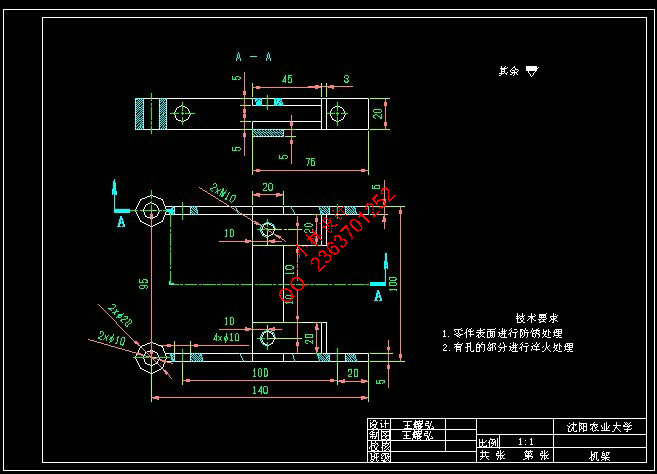

3.4悬挂装置与机架 25

3.5限深轮 26

3.6地轮 27

4结论 28

参考文献 28

致 谢 30

摘要

近年来,随着我国经济结构和农业种植业结构的调整,蔬菜种植面积逐步增加,蔬菜产业在当地的经济收益上占有很大的比重。大多数蔬菜品种都采用育苗移栽的方式种植,而我国蔬菜移栽机械发展缓慢,长期以来蔬菜移栽一直以手工作业为主,制约了我国蔬菜产业的发展。因此实现移栽生产机械化是我过蔬菜产业亟待解决的关键问题。

本文在分析了国内外移栽机械研究概况、发展趋势以及现有主要机型特点的基础上,根据我国蔬菜生产的实际情况,设计并研制了新型的悬杯式蔬菜移栽机。针对吊篮式移栽机在钵苗过高时容易碰苗的问题,设计了悬杯式蔬菜移栽机,阐述了整机的结构及工作原理,并对关键部件进行了具体的结构设计。通过采用水平向后张开的悬杯结构,降低了落苗过程中的伤苗率,提高了整机的栽植质量。由于其悬杯水平左右开启,开口朝后,所以在特征参数 的条件下进行移栽作业时作业时,落苗后张开的悬杯从钵苗的侧面沿机组前进方向离开,有效地解决了现有吊篮式移栽机在钵苗过高的情况下落苗容易出现的碰苗问题。在理论分析的基础上,确定了悬杯式蔬菜移栽机整机的总体配置方案和栽植单体、传动系统、悬挂架、限深轮、地轮等零部件的具体结构,用三维设计软件SolidWorks建立了整机的三维模型,并对其进行干涉检查。

关键词:蔬菜移栽机;悬杯式;栽苗器

Abstract

In recent years, with the adjustment of the economic and agricultural planting structure of China are pushed forward, the acreage of vegetables gradually increases and the vegetable industry accounts for a large proportion of the local economic benefits. Most vegetable production adopts the technology of seedling nursing, but the vegetable transplanter in our country develops slowly and vegetable transplanting is mainly by manual work for a long time. It has seriously hampered the development of vegetable industry in China. So it has become an urgent issue to achieve seedling transplanting mechanization for our vegetable industry.

According to the actual situation of Chinese vegetable production, based on the analysis of domestic and foreign transplanter’s general situations, development trends and characteristics of existing models, a new cantilever cup vegetable transplanter is designed and manufactured. It uses a cantilever cup planting apparatus as the key component to load and plant seedlings. To solve the problem that the hanging basket transplanter is apt to impact the seedlings when the seedlings are too high,the cantilever cup vegetable transplanter was designed.The structure and the working principle of whole machine were introduced,and the detailed structure of key components was designed. By using the cantilever cup which splays in the horizontal plane and opens backwards,the rate of damaged seedlings in the process of dropping seedlings was reduced and the whole machine’S planting quality was improved.Because of its cantilever cup opening backwards in the horizontal plane, so when the vegetable transplanter works under the situation of of characteristic coefficients , the opening cup leaves the seedling from the side along whole machine’s forward direction, which effectively solve the problem that the existing hanging basket transplanter is apt to impact the seedlings when the seedlings are too high. Based on the theoretical analysis, the overall configuration of cantilever cup vegetable transplanter and the specific structure of transplanting unit, transmission system, suspension frame, depth wheel, and ground wheel were determined. Three-dimensional model of the machine was established by 3D design software SolidWorks and did the interference checking.

Key words:vegetable transplanter;cantilever cup;planting apparatus

|