|

设计描述:

文档包括:

word说明书一份,共56页,约15000字

CAD版本图纸,共18张

摘要

近年来,我国国用火箭燃料贮箱都是采用了搅拌摩擦焊(FSW)焊接。目前在火箭燃料贮箱的焊接过程中并没有具体统一的夹具使用,导致贮箱表面圆度与精度数值有起伏,甚至有些表面还有微型凹陷,所以设计一套火箭燃料贮箱在搅拌摩擦焊焊接过程中专用的组合夹具迫在眉睫。

火箭燃料贮箱主要由三部分组成,可以分为2个主要工件,分别是中间的薄壁筒体以及两端的半球面体。其中半球面体一般先由6块瓜瓣片形状的金属板焊接成半球面体状,再和一个端盖焊接成完整的贮箱球面盖,所以这里需要一套完整的焊接夹具。由于搅拌摩擦焊焊接机器的旋转局限性,焊接完成两个瓜瓣片之间的纵缝后,需要整个工件和夹具一起旋转60°之后才能继续焊接另外的纵缝,所以需要另外设计一台特定配置的回转工作台用来带动整个夹具和工件一起转动。设计薄壁筒体夹具时,由于用于筒体焊接的搅拌摩擦焊机器有绕中心轴旋转功能,所以不必再设计新的工作台。

设计过程:在FSW的工作原理和工件的结构基础上分析夹具需要的定位面和夹紧面;在Pro/E上绘制初步的三维模型,设计出大概的尺寸;对夹具整体的外形和尺寸进行优化,分析考虑其实用性并进行修改;通过球面体夹具的尺寸算出体积和重力;根据其他数据设计对应的回转工作台;受力分析和校核;在Pro/E上进行零件的装配;根据三维零件模型和装配模型在AutoCAD上绘制二维图;Pro/E上夹具、回转工作台、工件的配合演示。

关键字:火箭燃料贮箱;夹具;回转工作台;设计;筒体;球面体

Abstract

In recent years, friction stir welding (FSW welding) is used in China's rocket fuel tanks. At present, the use of chucking in the welding process of rocket fuel tank lack of standardization, resulting in the record of tank’s circular degree and accuracy up and down, even some surfaces emerge micro sunken. To design a suit of special combination fixture for rocket fuel tank in the friction stir welding process is extremely urgent.

Rocket fuel tank is mainly composed of three parts, can be divided into two main parts, which are thin-wall cylinder and both ends of the hemispherical work piece. Generally, the hemispherical work piece is welded by six scalloped segment metal plates at first, then weld with end cover. It requires a complete set of welding fixture. Due to the limitation of the FSW welding machine’s rotating, after welding the longitudinal seam between two scalloped segment plates, the work piece and fixture need to rotate 60 degrees to continue longitudinal seam welding. It needs designing a specific configuration rotary working-table to drive the fixture and work piece rotate together. When designing the thin-wall cylinder’s fixture, there is no need to design a new working-table because of the standard machine.

The design process: Analyze the locating surface and clamping surface of fixture’s need on the basis of FSW’s operational principle and work piece’s structure; Draw the initial 3D model in Pro/E, design outline dimensions; Optimize the whole size and shape of fixture, considering the practicability and modify; Figure out volume and gravity on the basis of the hemispherical work piece fixture’s size, design the corresponding rotary working-table on the basis of other date; Force analysis and check; Assemble parts in Pro/E; To draw 2D diagram in AutoCAD according to the 3D part model and assembly model; Show the assemble in Pro/E.

Keywords: rocket fuel tank; fixture; rotary working-table; design; cylinder; the hemispherical

目 录

摘 要

Abstract

第1章 绪论 1

1.1 研究的目的及意义 1

1.2 国内外研究现状 3

1.2.1 薄壁筒体夹具研究现状 3

1.2.2 球面体夹具研究现状 4

1.3 主要研究内容 6

1.3.1 筒体夹具分析与设计 6

1.3.2 半球面体夹具分析与设计 6

1.3.3 拟解决的主要问题 7

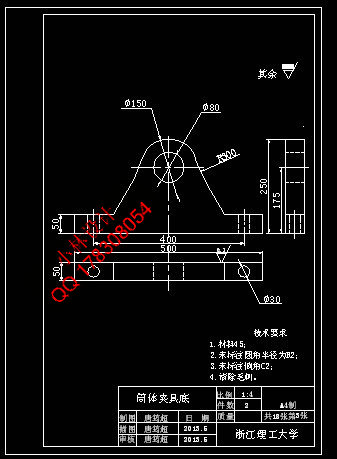

第2章 球面体夹具设计 7

2.1 机械加工工艺分析 7

2.2 夹具的结构方案 8

2.3 半球面体夹具装配图 12

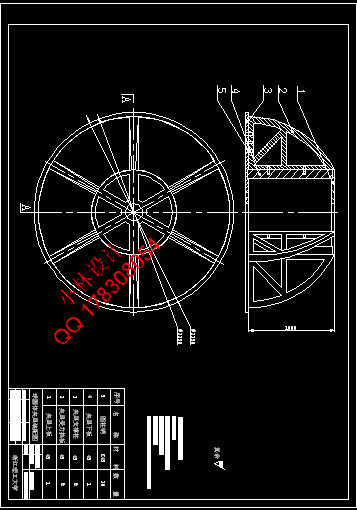

第3章 回转工作台设计 13

3.1 工作台方案分析 13

3.2 电机的选择 14

3.3 动力参数计算 15

3.4 齿轮传动设计 16

3.5 涡轮蜗杆传动设计 20

3.6 轴、键、轴承及联轴器的设计和选择 24

3.7 轴的校核 29

3.8 回转工作台装配图 35

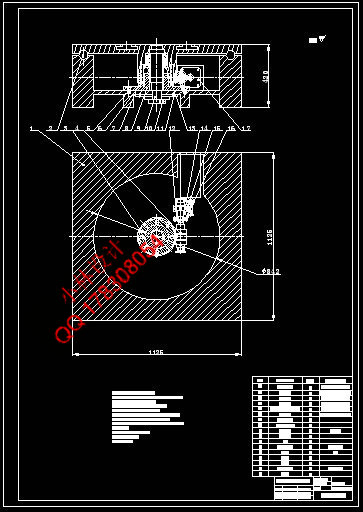

第4章 筒状体夹具设计 36

4.1 机械加工工艺分析 36

4.2 夹具的结构方案 37

4.3 筒体夹具的装配图 41

第5章 AutoCAD与Pro/E软件简介 42

5.1软件简介 42

5.2三维模型 43

第6章 总结 44

参考文献 45

致 谢 46

附录 47

|