|

设计简介 |

设计描述:

文档包括:

word说明书一份,共39页,约21000字

CAD版本图纸,共6张

目 录

摘要.....................................................

第一章 绪论.............................................1

1.1 论文研究的背景和意义.............................1

1.2 试验平台研究的必要性.............................2

1.3 国内外研究的进展............................... .2

1.4 实验台的类型.....................................2

1.5 现有试验装置的局限...............................5

1.6 多功能实验台的设计要求和设计内容.................5

第二章 试验台的总体设计 ................................6

2.1 实验台的总体要求.... ............................6

2.2 实验台的功能分析与定位...........................7

2.3 改造方案对比.....................................7

2.4 本实验台的优点分析...............................9

第三章 关键零部件的设计与计算...........................10

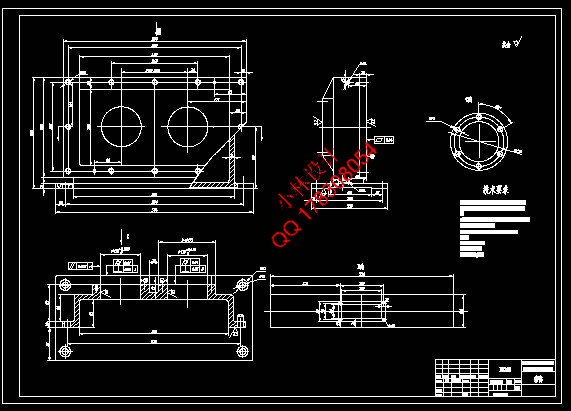

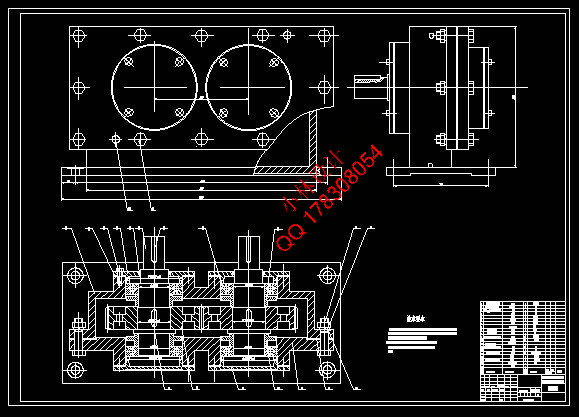

3.1 齿轮的设计与计算.................................10

3.2 轴的设计计算.....................................13

3.3 滚动轴承的选择与寿命计算.........................17

3.4 联轴器的选择.....................................18

第四章 传感器的选择.....................................20

4.1传感器.............................................20

4.2 传感器的分类......................................21

4.3 传感器的选用......................................22

4.4 STY扭矩传感器的基本原理..........................22

4.5 STY系列扭矩传感器技术性能指标....................24

4.6 STY扭矩传感器安装使用:..........................24

4.7 使用特别注意事项.................................25

第五章 数据采集与处理...................................26

5.1 数据采集系统的原理与结构.........................26

5.2 效率的计算的原理.................................26

第六章 中心距的设计.....................................27 6.1 中心距的设计.....................................27

6.2 理想的中心距.....................................27

第七章 螺旋滚珠式机械加载器..............................28

7.1 加载器结构原理...................................28

7.2 螺旋滚珠式机械加载器的特点.......................29

第八章 总结..............................................29

致谢...................................................30

参考文献...............................................31

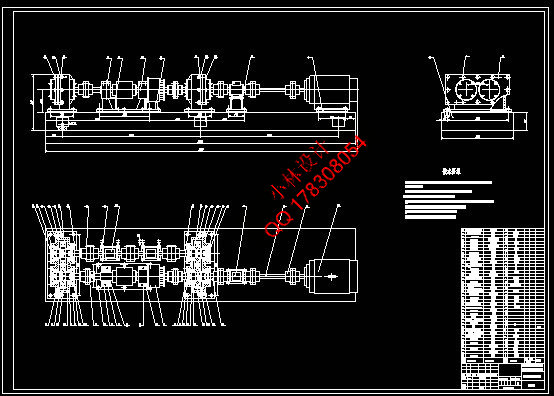

机械传动实验台的研究与设计

摘要:机械传动试验台是用试验的方法研究机械传动的各种失效形式并测定其承载能力、传动效率及有关性能的基本手段,长期以来我国的传动试验台的研制基本上还停留在传统的人工方式水平上。这些试验台都存在一个共同的缺点:自动化程度低,无法模拟实际工况对各种机械传动产品进行试验,试验过程的监控及试验数据的采集和处理都较麻烦且准确性低。近些年来的研究取得一些进步,但目前的绝大多数实验台还只能进行恒定载荷加载或简单的程序控制阶梯加载,实验结果与现场测试依然有较大的差距。

本文提出改进湘潭大学机械原理实验室的齿轮试验台的方案,在成本不高的情况下,增加其测试功能--可以测量联轴器,离合器,带传动的效率和寿命,使其成为一台多功能机械传动试验台.

关键词:

机械传动 齿轮 联轴器 离合器 效率 寿命

Mechanical transmission experiment station designed Research

Abstract: Mechanical transmission experiment platform is a basic device for the study of some types of mechanical failure, the transmission efficiency, and the related performance of mechanical transmission and the measurement of the load ability. In our country, the ability of studying and designing mechanical transmission experiment platform is still at such stage that the experimental device is operated manually, leaving some common shortcomings among those platforms, such as low-automation because they can't simulate real working environment accurately during testing the mechanical products, and the accuracy of acquiring data is low. Although a number of achievements have been made in recently years, these platforms can just perform with invariant load or with simple skip load. There is a big gap between experiments and real working environment.

This paper presents improved mechanical principle of Xiangtan University laboratory test gear program, the costs are not high in the circumstances, increase its test function -- can be measured coupling clutch, belt drive efficiency and lifespan, as a multifunctional mechanical transmission test.

Keyword: Mechanical Transmission Gear Coupling Clutch Efficiency Lif

|