|

|

|

|

设计名称 |

码坯机升降机构的设计 |

|

|

设计编号 |

Z064 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

5500字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

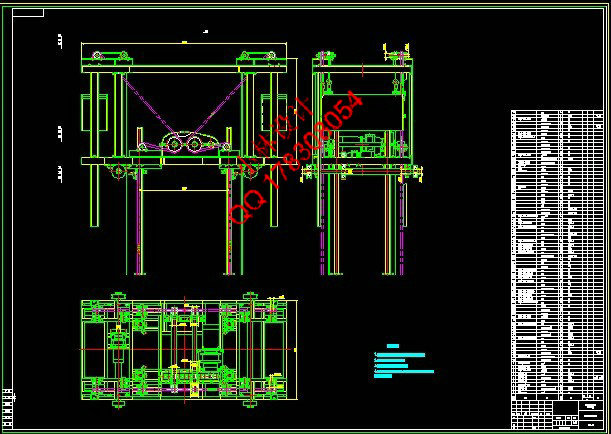

文档包括: CAD版本图纸,共23张 摘要 现在,码坯机主要由切条机、切坯机、分坯机、夹盘机构、行走机构、升降机构、旋转机构和电气系统等组成。其中升降机构是其中一个重要部分,现在升降机构一般采用液压升降与滚子链升降两种方法。液压升降因为液压元件的制造精度要求较高、价格较贵,而且不能得到严格的传动比、效率较低。又由于工作性能易受到温度变化的影响,因此不宜在很高或很低的温度条件下工作,所以设计采用滚子链升降。升降采用滚子链,使其运动准确,避免打滑现象,同时利用四个导向柱,增加设备的稳定性。滚子链由大小链轮带动,共四组,布于四周,通过摆线针轮减速机通过齿轮箱带动两根轴实现同步上升。最后在车架两端加上配重,通过钢丝绳与夹盘机构连接,这样可以减轻滚子链受力,减小功率。行走机构通过另一摆线针轮减速机带动行走轴行走。此为本文设计方案,并且通过计算,论证了该设计方案的可行性。 关键词:码坯机;升降机构;行走机构;滚子链升降

Abstract Now, setting machine is mainly composed of a cutting machine, cutting machine, cutter, chuck mechanism, running mechanism, lifting mechanism, a rotating mechanism and electrical system. The lifting mechanism is one of the most important parts, now lifting mechanism generally adopt hydraulic lifting and roller chain lifting two methods. Hydraulic lift for hydraulic components of the manufacturing precision is high, the price is more expensive, but can not be a strict transmission ratio, low efficiency. Because the working performance are susceptible to the influence of temperature change, therefore not at very high or very low temperature conditions, so the design of the roller chain lifting. Lifting the roller chain, the motion accuracy, avoid the slip phenomenon, at the same time using four guide posts, increases the stability of equipment. Roller chain sprocket drive by size, a total of four groups, the cloth around, through the cycloidal pinwheel speed reducer through the gear box drives two axis synchronous rise. In the final frame ends with counterweight, through the steel wire rope and the chuck body connected, this can reduce roller chain stress, reduce power. Walking mechanism through another cycloid reducer drive shaft walk walking. This is the design, and through calculation, it proves the feasibility of design scheme.

Key words :Setting machine; lifting mechanism; running mechanism; the roller chain lifter

1 绪论 1 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1